An automatic adjustment device and adjustment method for the return flow of mixed liquid in a small purification tank

A technology for automatic adjustment of mixed liquid return flow, applied in chemical instruments and methods, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve the problem of damaging denitrification conditions, unstable gas volume, and large time-varying coefficients, etc. problems, to achieve the effect of ensuring anoxic environment and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

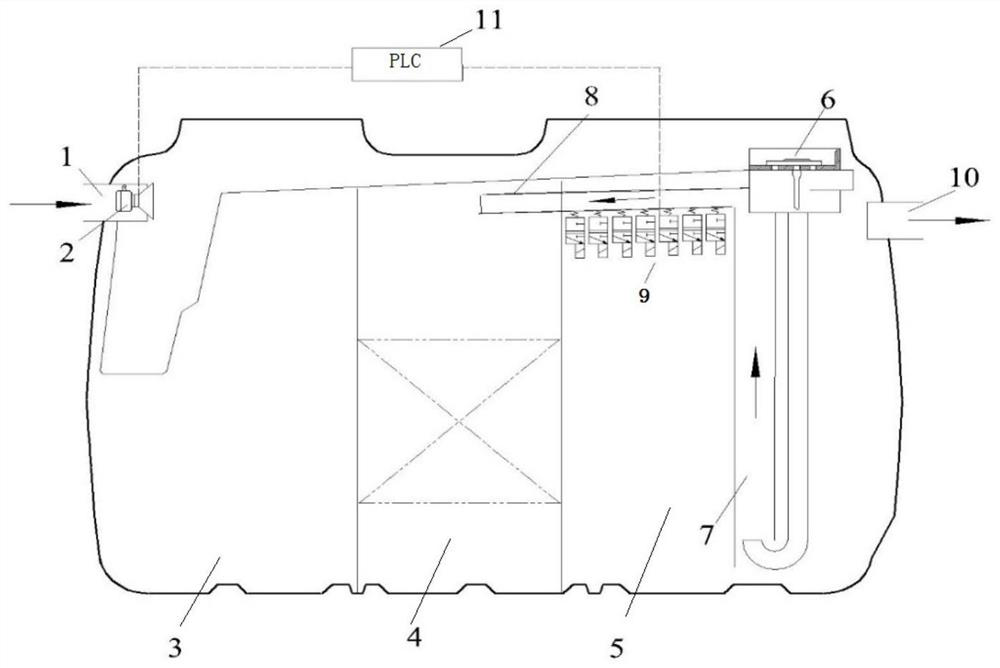

[0025] Embodiment 1: as figure 1 As shown, a small-scale purification tank mixed liquid return flow automatic adjustment device, the automatic adjustment device includes a water inlet tank 1, an ultrasonic liquid level detection device 2, a pre-settling area 3, an anoxic denitrification area 4, and an aerobic nitrification area 5 , air lift valve 6, mixed liquid lift pipe 7, return tank 8, solenoid valve assembly 9, water outlet tank 10 and controller 11 (program logic controller, PLC); solenoid valve assembly 9 is composed of 7 parallel solenoid valves, The solenoid valve assembly 9 and the ultrasonic liquid level detection device 2 are respectively connected to the controller 11 in communication.

[0026] The water inlet of the automatic adjustment device is provided with a water inlet tank 1 for the sewage to be treated to enter, and an ultrasonic liquid level detection device 2 for detecting the water level depth of the water inlet tank is installed in the water inlet tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com