Power supply circuit for filament of high-power electronic tube

A technology of power supply circuit and electron tube, applied in the direction of output power conversion device, DC power input conversion to DC power output, electrical components, etc., can solve the problem of limited adjustment range and achieve effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

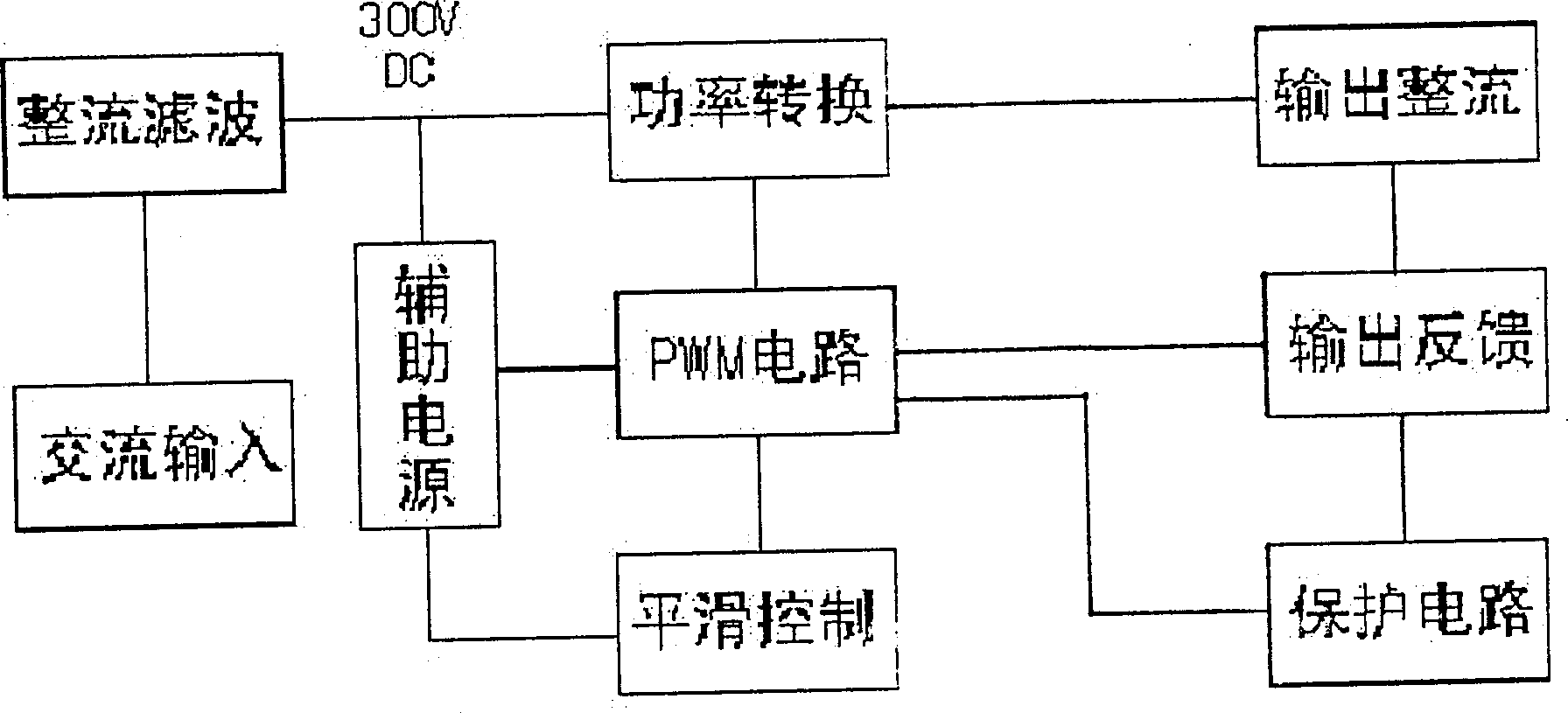

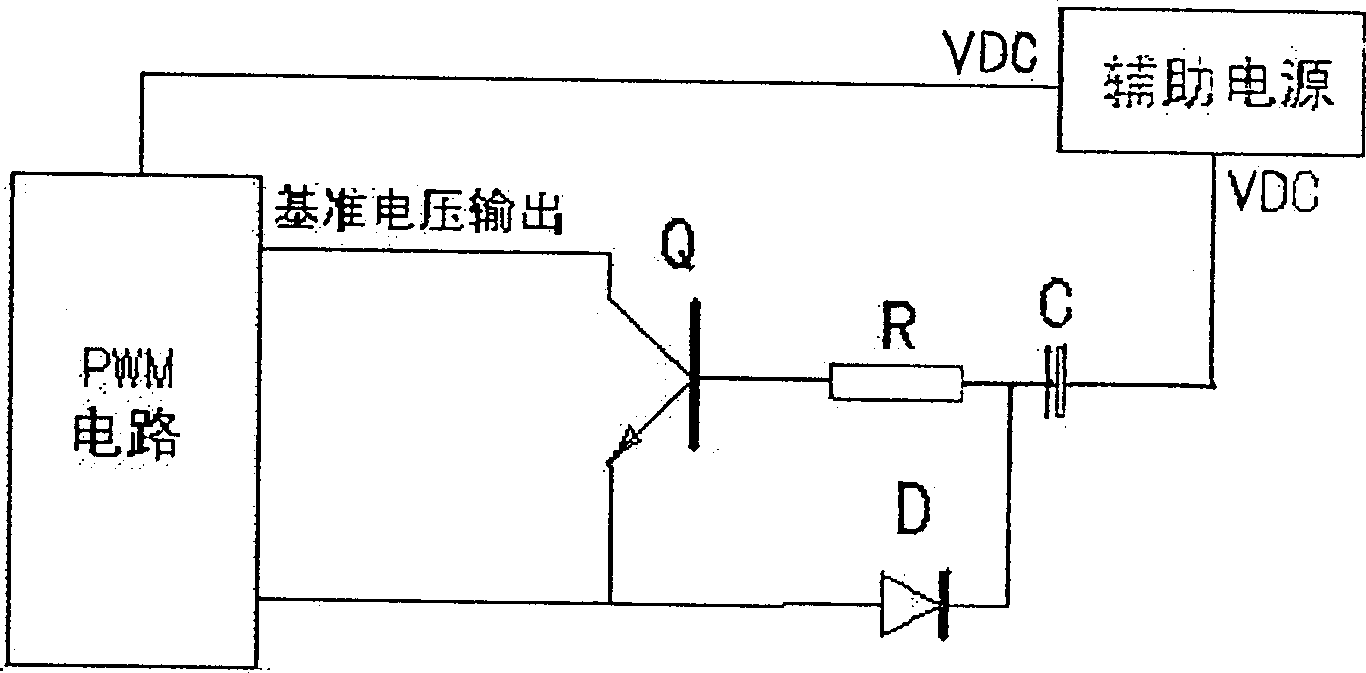

[0022] See attached figure 1 , figure 2 , the present invention adopts the switch regulated power supply with pulse width modulation circuit PWM as the control circuit, and provides a smooth control circuit for the switch regulated power supply that can smoothly raise its reference voltage to the rated value from zero.

[0023] Such as figure 1 As shown, the switching regulated power supply in this embodiment takes the AC power supply as the AC input, directly rectifies and filters to obtain a 300V DC high voltage, and then sends it out in two ways, one way provides power for power conversion, and the other way generates 12-25V auxiliary power supply. As a working power supply for other unit circuits such as pulse width modulation. A series of output pulse voltages with adjustable pulse width are generated in the pulse width modulation circuit, and the voltage is fed back to the output terminal of the power tube to control the power tube to be in the on or off state, and th...

Embodiment 2

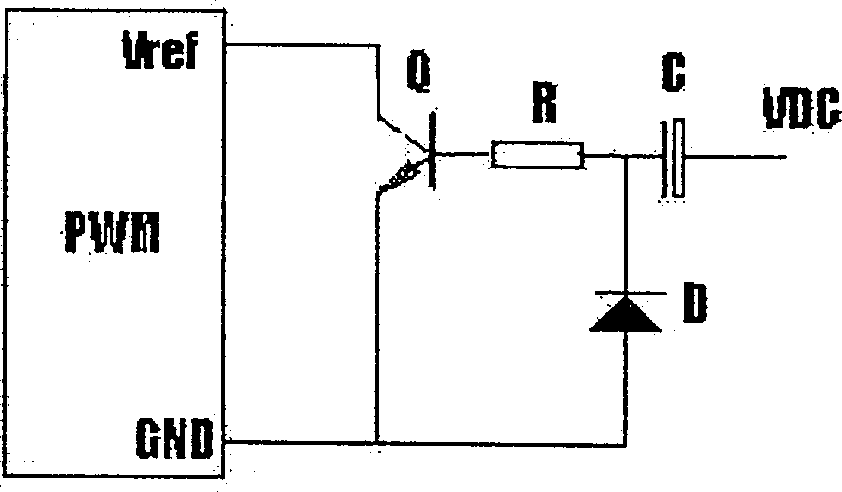

[0029] see Figure 4 , Image 6 The difference from the above-mentioned embodiment 1 is that in this embodiment, the collector of the transistor Q is connected to the reference voltage output terminal of the voltage comparator of the XX1525 chip, which is pin 1, and the emitter is grounded. The circuit is especially suitable for the reference voltage input terminal of the voltage comparator to have external pins on the chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com