Environment-friendly water-based metallic colored paint

A metallic color, water-based technology, applied in the field of color paint, can solve the problems of physical health threat and air pollution of paint construction personnel, achieve excellent metallic luster and decorative properties, reduce VOC content, and reduce the harm to the environment and construction personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

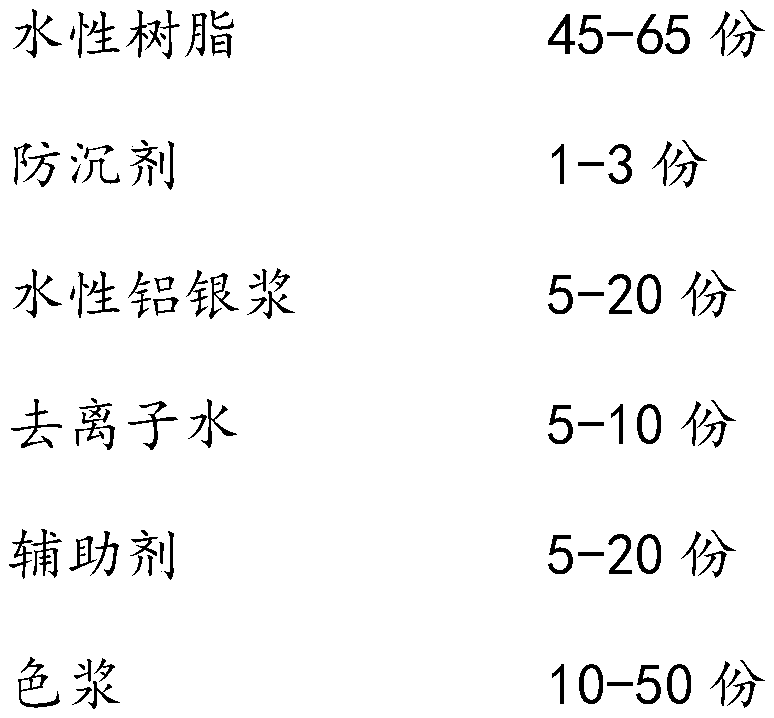

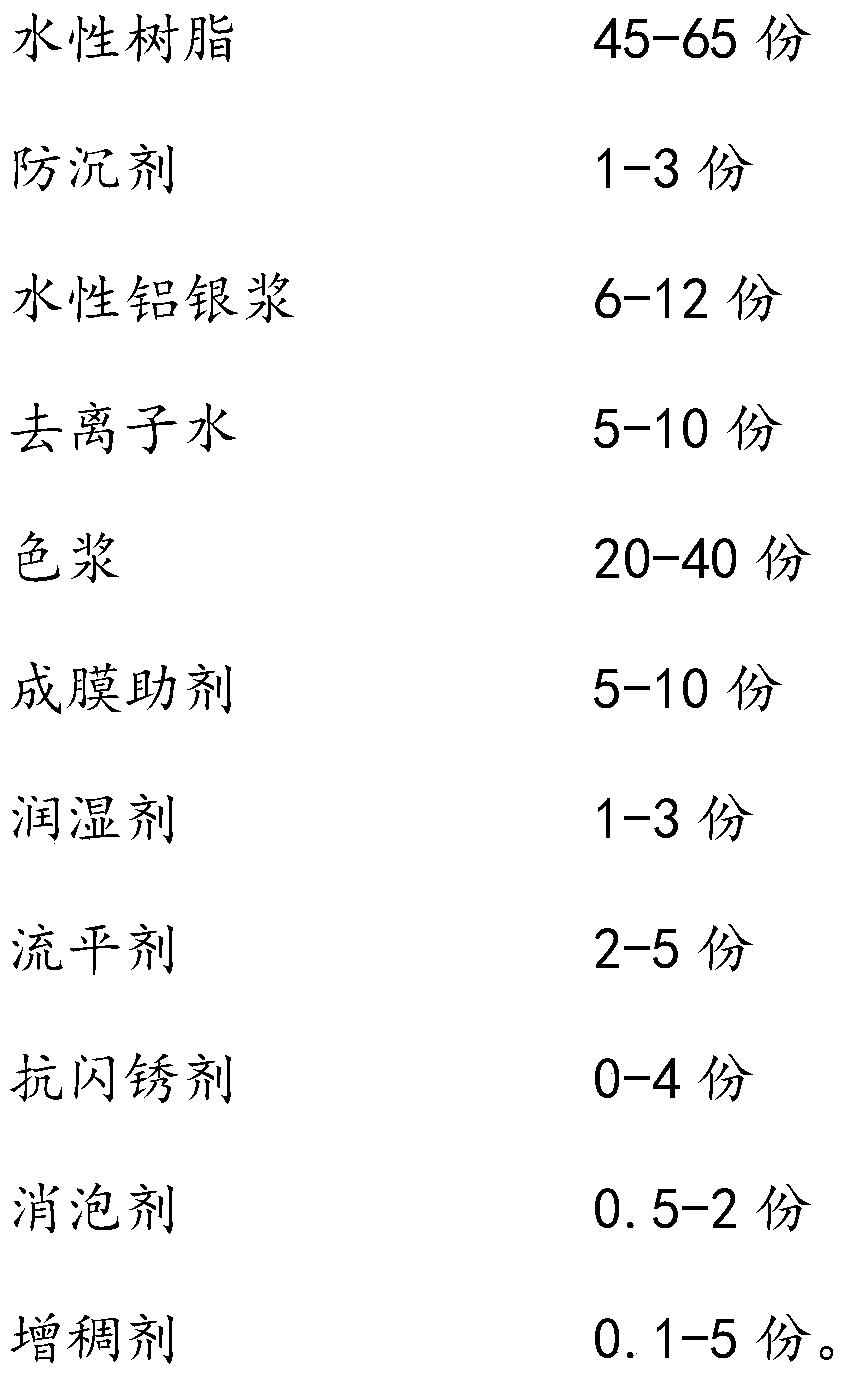

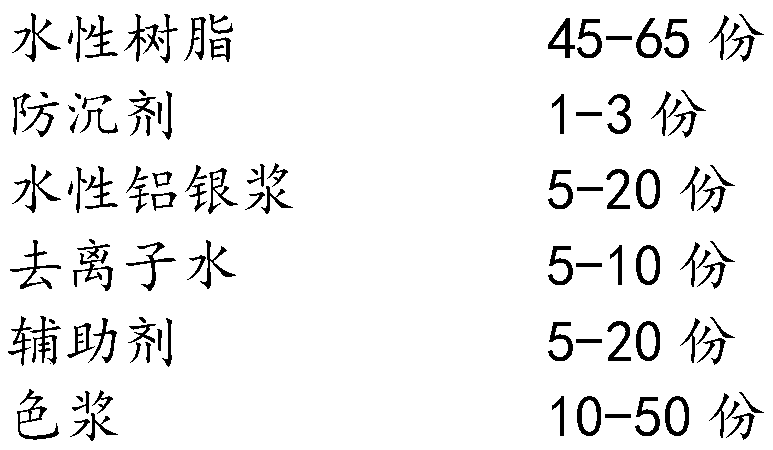

[0028] A kind of environment-friendly water-based metallic color paint 1, comprises A, B two components, and A component comprises the raw material of following weight ratio:

[0029] 50 parts of water-based resin, 20 parts of water-based red paste, 10 parts of water-based aluminum silver paste, 2 parts of wetting agent, 3 parts of leveling agent, 0.5 part of anti-flash rust agent, 1 part of defoamer, 0.4 part of thickener, composition 5 parts of membrane aids, 8.1 parts of industrial pure water.

[0030] Preparation method: 50 parts of water-based resin, 2 parts of wetting agent, 3 parts of leveling agent, 0.5 part of anti-flash rust agent, 1 part of defoamer, 8.1 parts of industrial pure water, thickener are added under the condition of stirring at 800 rpm 0.4 parts, stirred for 10 minutes, added 5 parts of film-forming aids, stirred for 20 minutes, continued to add 20 parts of red color paste, 10 parts of water-based aluminum silver paste, stirred for 30 minutes, the prepar...

Embodiment example 2

[0033] An environmentally friendly water-based metallic paint 2, including two components A and B, and the A component includes the following raw materials in weight ratio:

[0034] 45 parts of water-based resin, 35 parts of water-based blue paste, 5 parts of water-based aluminum silver paste, 2 parts of wetting agent, 2 parts of leveling agent, 1 part of anti-flash rust agent, 1 part of defoamer, 0.6 part of thickener, 4 parts of film-forming aids, 4.4 parts of industrial pure water.

[0035] Preparation method: 45 parts of water-based resin, 2 parts of wetting agent, 2 parts of leveling agent, 1 part of defoamer, 1 part of anti-flash rust agent, 4.4 parts of industrial pure water, thickener are added under the condition of stirring at 800 rpm 0.6 parts, stirred for 10 minutes, added 4 parts of film-forming aids, stirred for 20 min, continued to add 35 parts of blue color paste, 5 parts of water-based aluminum silver paste, stirred for 30 minutes, the preparation of component...

Embodiment example 3

[0038] An environmentally friendly water-based metallic paint 3, including two components A and B, and the A component includes the following raw materials in the weight ratio:

[0039] 60 parts of water-based resin, 13 parts of water-based black paste, 7 parts of water-based aluminum silver paste, 2 parts of wetting agent, 3 parts of leveling agent, 1 part of anti-flash rust agent, 1 part of defoaming agent, 0.5 part of thickener, composition 5 parts of membrane aids, 7.5 parts of industrial pure water.

[0040] Preparation method: 60 parts of water-based resin, 2 parts of wetting agent, 3 parts of leveling agent, 1 part of defoamer, 1 part of anti-flash rust agent, 7.5 parts of industrial pure water, 0.5 parts of thickener are added under the condition of stirring at 800 rpm part, stirred for 10 minutes, added 5 parts of film-forming aids, stirred for 20 minutes, continued to add 20 parts of black color paste, stirred for 30 minutes, the preparation of component A was comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com