An opposed burner system for a supercritical carbon dioxide coal-fired boiler

A carbon dioxide, coal-fired boiler technology, which is applied in the combustion of various fuels, the combustion of lump fuel and powder fuel, the combustion of lump fuel and gaseous fuel, etc. Large temperature deviation, unstable flame and other problems, to achieve the effect of efficient and stable pulverized coal combustion, preventing local over-temperature, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

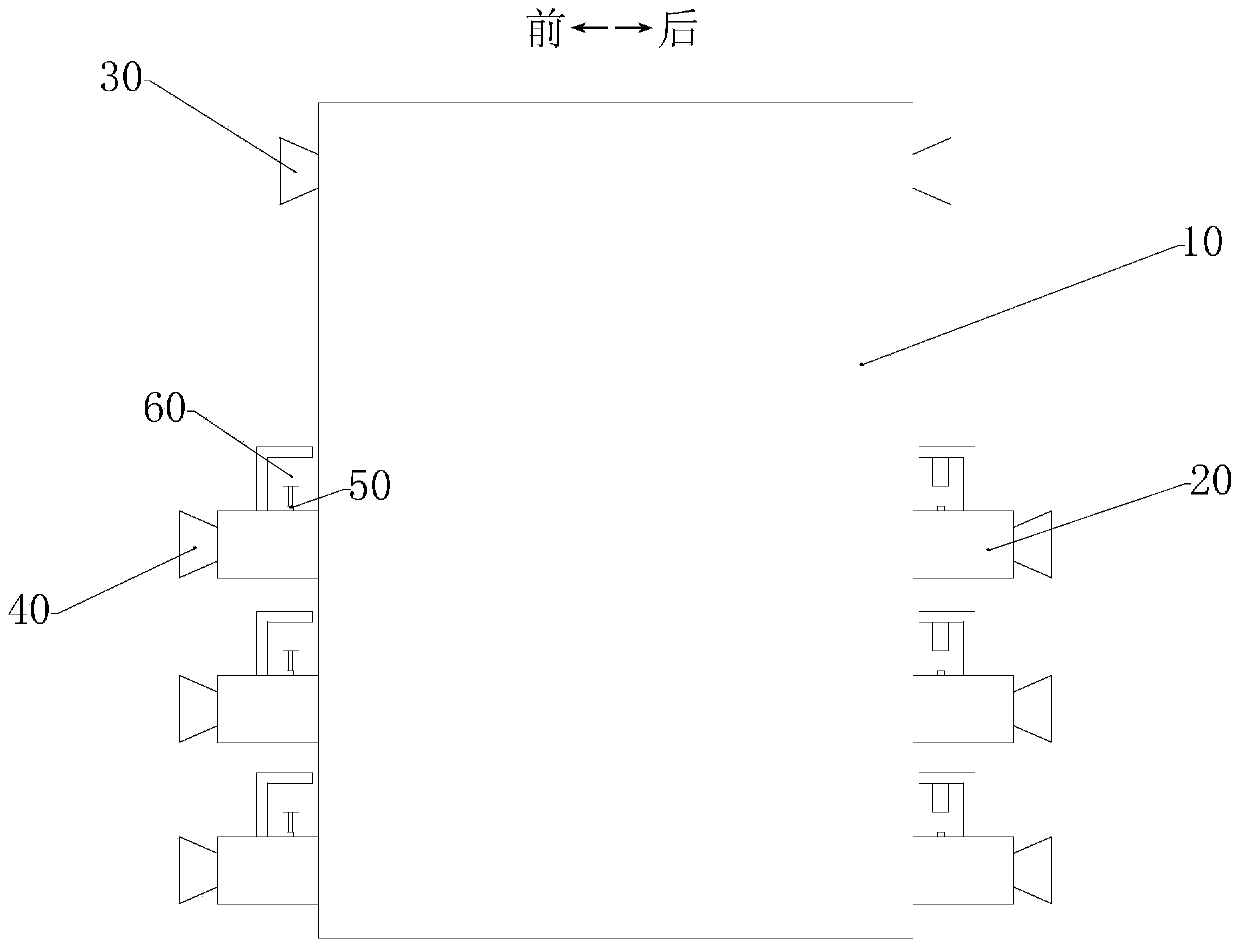

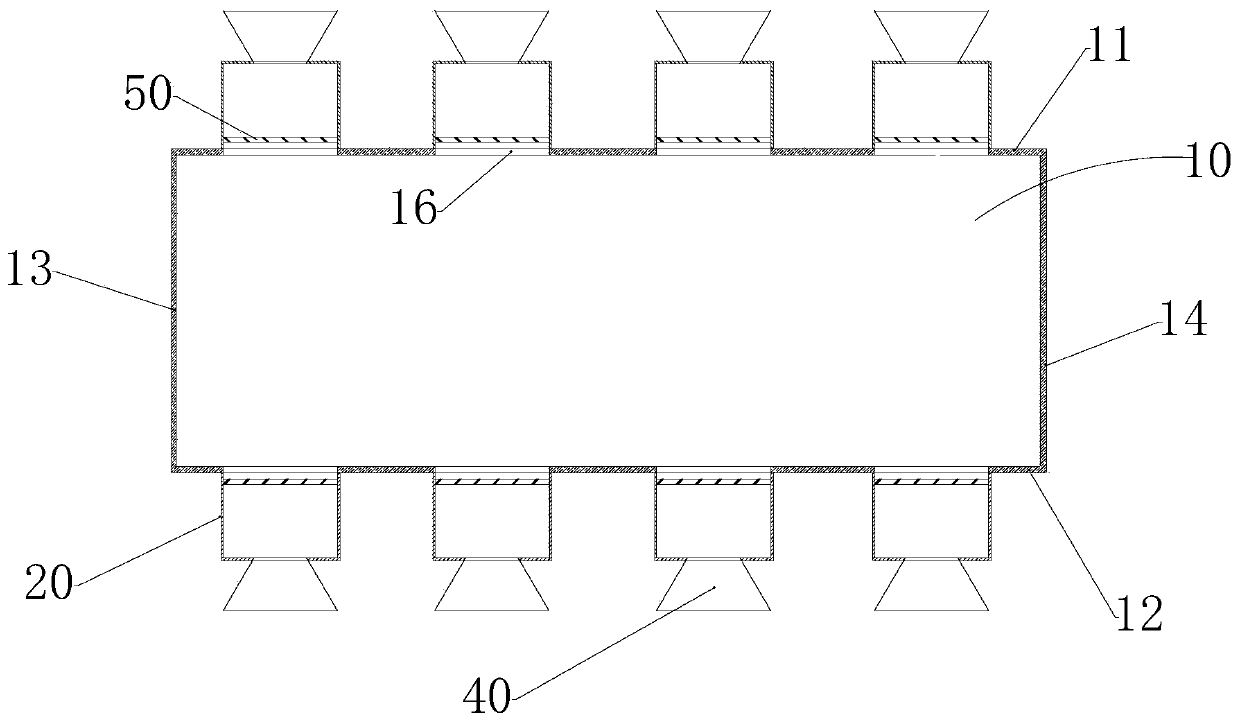

[0035] Under a specific load requirement, the second burner 40 is symmetrically installed on the front side wall 11 and the rear side wall 12 of the boiler 10, and is equidistantly opposed to each other. The additional fuel chamber 20 is a rectangular parallelepiped structure. Correspondingly, the baffle 50 is a rectangular parallelepiped structure, and the length L of the additional fuel chamber 20 along the movement direction of the primary wind is 1.5L 0 , the length d of the additional fuel chamber 20 perpendicular to the movement direction of the primary wind is 0.2H, the opening s of the baffle plate 50 is selected as 50%, L 0 is the ignition distance, and H is the width of the wall of the boiler 10 where the second burner 40 is arranged.

Embodiment 2

[0037] Under another specific load requirement, the second burner 40 is symmetrically installed on the front side wall 11 and the rear side wall 12 of the boiler 10, and is equidistantly opposed to each other. The additional fuel chamber 20 is a cylindrical structure, corresponding to Yes, the baffle plate 50 is a cylindrical structure, and the length L of the additional fuel chamber 20 along the movement direction of the primary wind is 1.5L 0 , the diameter d of the additional fuel chamber 20 perpendicular to the movement direction of the primary wind is 0.2H, the opening s of the baffle plate 50 is selected as 50%, L 0 is the ignition distance, and H is the width of the wall of the boiler 10 where the second burner 40 is arranged.

Embodiment 3

[0039] Under another specific load requirement, the second burner 40 is symmetrically installed on the front side wall 11 and the rear side wall 12 of the boiler 10, and is equidistantly opposed to each other. The additional fuel chamber 20 is a square structure, corresponding to Yes, the baffle plate 50 is a cube-shaped structure, and the length L of the additional fuel chamber 20 along the movement direction of the primary wind is 1.5L 0 , the outlet diameter d of the additional fuel chamber 20 perpendicular to the movement direction of the primary air is 0.2H, the opening s of the baffle plate 50 is selected as 50%, L0 is the ignition distance, and H is the wall surface of the boiler 10 where the second burner 40 is arranged width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com