Supported gold nanocluster catalyst as well as preparation method and application thereof

A gold nano-cluster, supported technology, applied in the field of supported gold nano-cluster catalysts and its preparation, can solve problems such as difficult to achieve catalytic activity, reaction conversion rate, unstable product selectivity, etc., achieve low equipment requirements, Good industrial application prospects, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for preparing gold nanoclusters, specifically as follows:

[0054] (1) 20mM HAuCl 4 ·3H 2 O solution 0.25mL, mixed with 3-mercaptopropionic acid solution (MPA) 2mL in 2.35mL ultrapure water to form MPA-Au complex.

[0055] (2) Add 0.3mL of 1mol / L NaOH solution to the above solution, then add 0.1mL of the above NaBH 4 solution, magnetically stirred for 3h, and collected by centrifugation (8000rpm, 4min) to obtain Au 25 (MPA) 18 Nanoclusters, i.e. Au 25 (MPA) 18 NCs.

[0056] Among them, NaBH 4 The solution was prepared as follows: 43 mg of NaBH 4 Dissolve the powder in 10mL of 0.2mol / L NaOH solution to obtain the product.

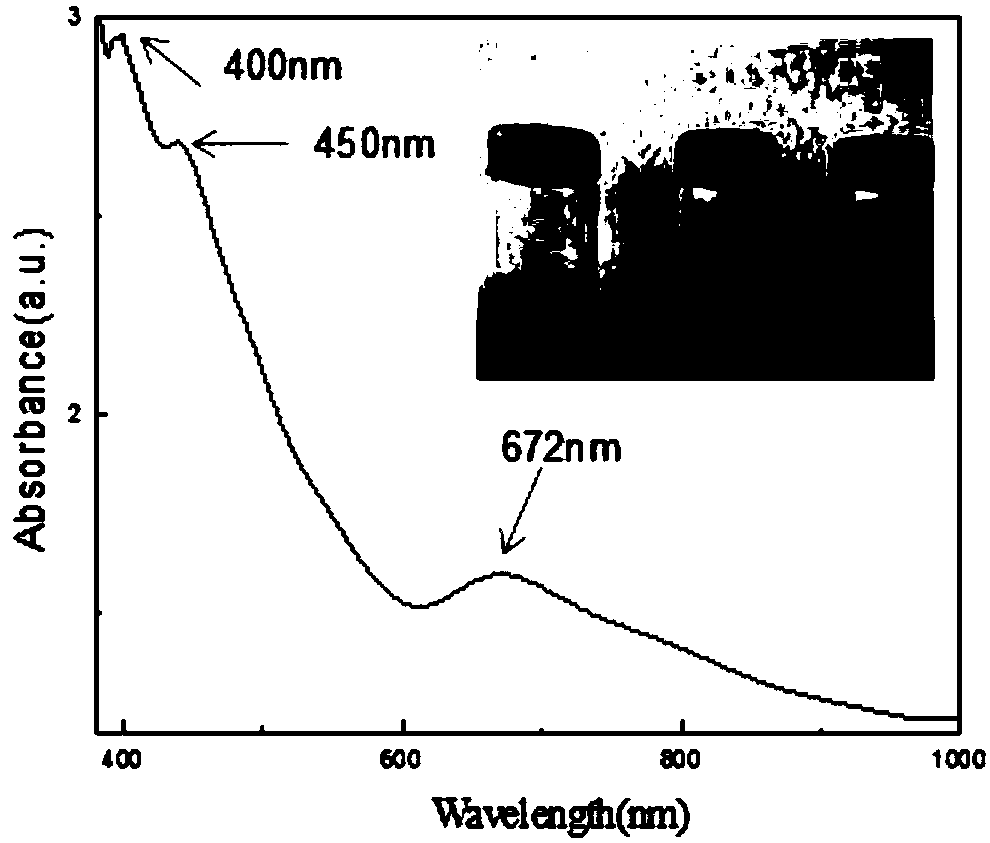

[0057] For the Au prepared above 25 (MPA) 18 NCs were characterized by UV-Vis, and the results were as follows figure 1 shown. Depend on figure 1 It can be seen that Au 25 (MPA) 18 NCs have triple absorption peaks in the ultraviolet-visible region: (1) the absorption peak at 672nm is attributed to the ...

Embodiment 2

[0059] Example 2 Nano CeO 2 Preparation of vector

[0060] Add 60mL of 7mol / L NaOH solution to 20mL of 0.25mol / L Ce(Ac) through a constant pressure funnel 3 In the solution, control the dropping rate to 3 seconds / drop, magnetically stir for 0.5h, transfer the solution to a hydrothermal kettle, heat it in water at 180°C for 24h, collect the obtained solid by centrifugation, and then wash it three times with deionized water and absolute ethanol at intervals. Dry at 100°C for 24 hours, and grind thoroughly in a mortar to obtain a sample.

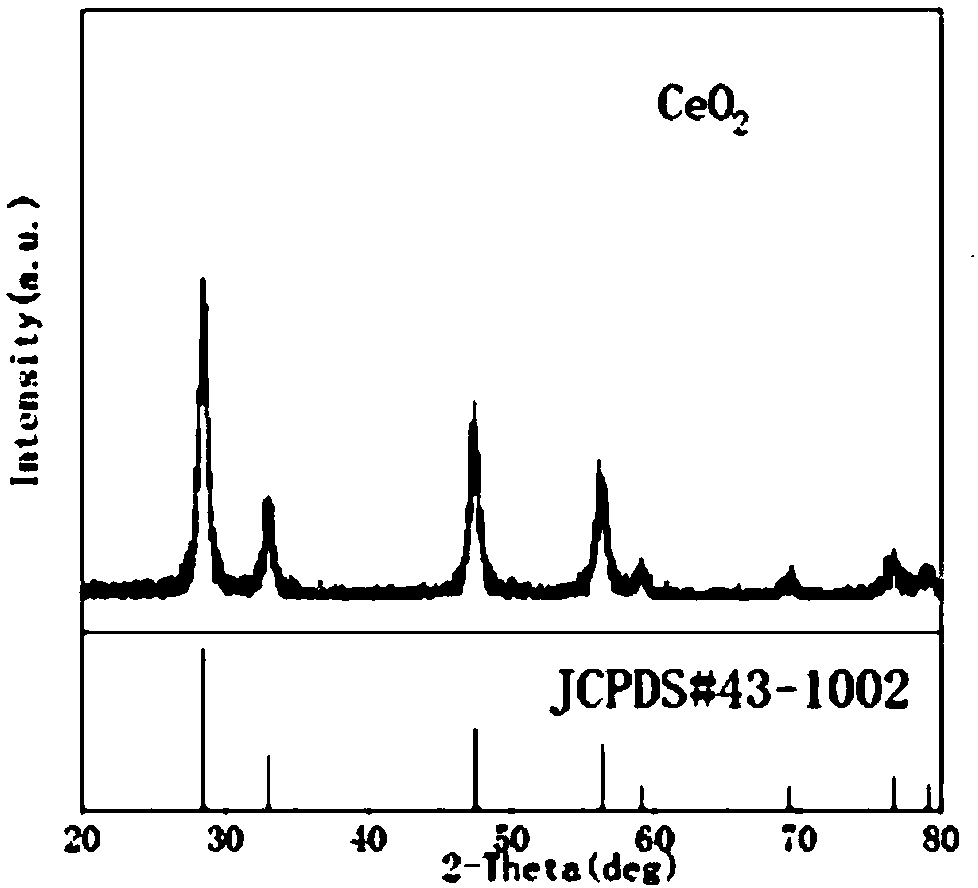

[0061] Adopt X-ray diffraction (XRD) to characterize the sample that prepares, the result is as follows image 3 As shown, compare it with the standard card (JCPDS#43-1002), the two are consistent, indicating that the prepared sample is pure CeO 2 . And carry out SEM characterization to it, the result is as follows Figure 4 As shown in a, the rod-like structure (nano-rods) can be observed in the figure, and the prepared nano-rods have hig...

Embodiment 3

[0062] Example 3 Au 25 (MPA) 18 NCs / CeO 2 preparation of

[0063] With the Au prepared in Example 1 25 (MPA) 18 NCs powder is used as the active ingredient, which is loaded on the carrier. Wherein, the carrier is the CeO prepared in Example 2 2 nanorod powder.

[0064] CeO prepared in 500mg embodiment 2 2 The Au prepared in the embodiment 1 of nanorod powder and 5mg 25 (MPA) 18 Disperse NCs powder in 10mL of dichloromethane, seal and stir for 24h, let stand to separate layers, dry the bottom layer at 60°C for 4h, and calcinate at 300°C for 2h (heating rate 2°C / min) to obtain Au 25 (MPA) 18 NCs / CeO 2 , where the mass fraction of loaded Au is about 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com