Pharmaceutical formulation with high stability and dissolution and manufacturing process

A technology of pharmaceutical dosage form and high stability, applied in the field of preparing the pharmaceutical dosage form, can solve problems such as poor solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

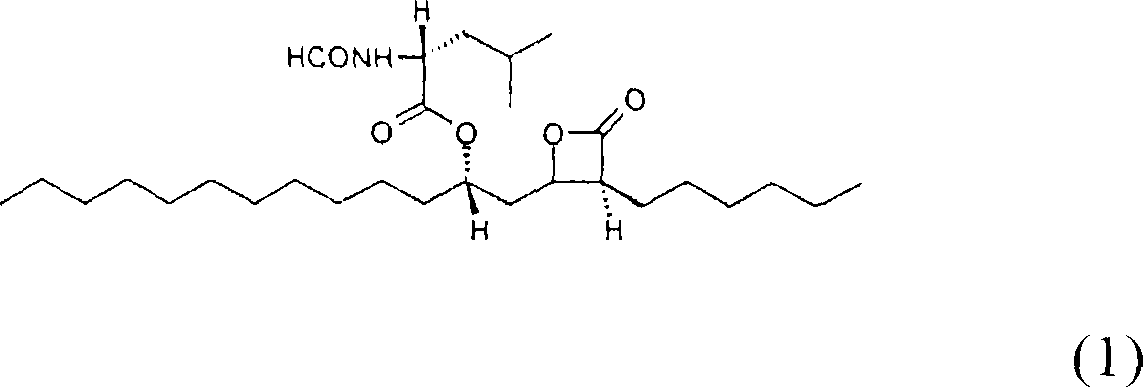

Image

Examples

Embodiment 1

[0043] Heat 10 grams of polyethylene glycol 400, 10 grams of polyoxyethylene castor oil (Cremophor (Kremophor)), 10 grams of polysorbate and 5 grams of tocopherol acetate (tocopherolacetate) to 40-60 ° C, and then To this was added 120 grams of orlistat. The mixture was uniformly stirred to prepare a pale yellow transparent liquid dosage form. This liquid state transforms into an opaque solidified state at room temperature.

[0044] A portion is used for liquid stability testing. Other fractions are adsorbed to an adsorbent, to which excipients are then added. The obtained mixture was compressed to prepare tablets, followed by film coating (wrapping) to obtain 800 tablet samples.

[0045] 1) Cool a liquid sample to form a solidified mass. The solidified mass has a uniform shape and composition, and exhibits no phase separation and reagglomeration. A series of storage at low temperature (4°C) and high temperature (40°C) was repeated several times, after which a dissolution...

Embodiment 2

[0052] 10 grams of polyoxyethylene castor oil (Cremophor) was heated to 40-60° C. to obtain a clear liquid, and then 10 grams of polysorbate was added thereto while stirring gently. 120 grams of orlistat was added to the mixture and stirred evenly to form a pale yellow transparent liquid dosage form. This liquid state transforms into an opaque solidified state at room temperature.

[0053] A part was used to observe the state of the liquid, while the other part was absorbed to prepare tablets, followed by coating to obtain 800 tablet samples.

[0054] 1) Phase separation and re-agglomeration were not observed in liquid samples. Following the procedure of Example 1, a series of storage at low temperature and high temperature was repeated several times, after which a dissolution test was carried out. As a result, a dissolution rate of about 59% was obtained. These observations indirectly suggest that the solvent chosen in the present invention is suitable and necessarily maxi...

Embodiment 3

[0057] When mixing 10 grams of polyethylene glycol, 10 grams of polysorbate and 5 grams of tocopheryl acetate while heating to obtain a clear liquid, 120 grams of orlistat were added to the mixture. The obtained mixture was uniformly stirred to prepare a pale yellow transparent liquid dosage form. This liquid state transforms into an opaque semi-solidified state at room temperature.

[0058] Following the procedure of Example 1, certain fractions were isolated, rapidly absorbed, and then compressed to prepare tablets.

[0059] 1) During solidification, phase separation, reagglomeration and recrystallization of separated liquid samples were observed. Following the procedure of Example 1, a series of storage at low and high temperatures was repeated several times, after which a dissolution test was performed. As a result, a dissolution rate of about 23% was obtained. These observations suggest that solubilizers are an indispensable component for stable dissolution of dosage f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com