Gas-liquid two-phase flow measurement system

A measurement system and phase flow technology, which is applied in the field of new gas-liquid two-phase flow measurement system, can solve problems such as difficult industrial promotion and application, difficulty in phase holdup measurement, etc., and achieve low maintenance costs, simple structure, and enhanced spin effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below with reference to the accompanying drawings.

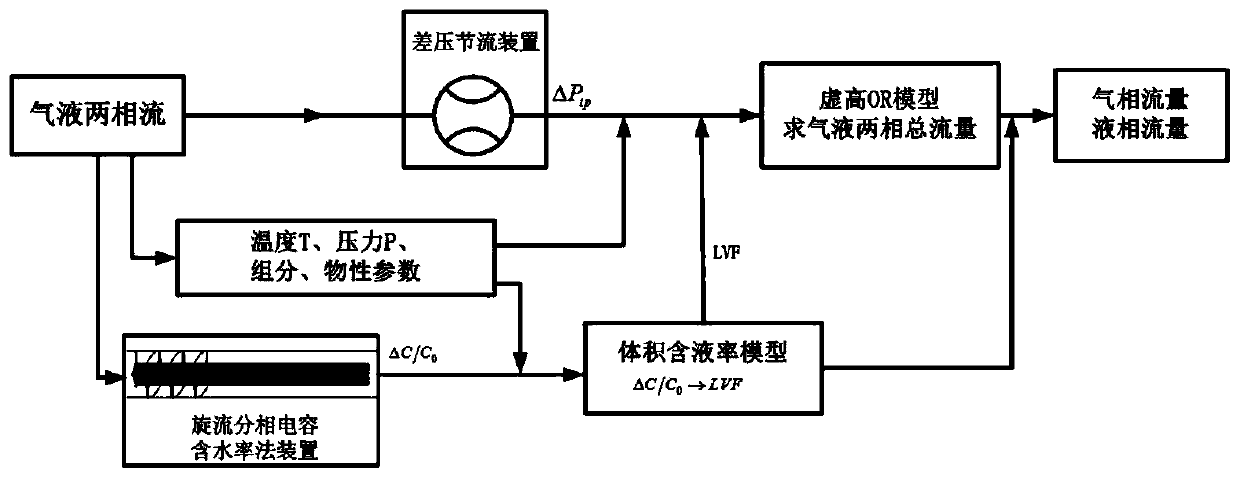

[0030] In order to avoid the influence of the flow pattern during the swirling phase-separation capacitor water content method device, the present invention uses a multi-blade diversion type swirl phase-separation capacitor water content method device to rectify and separate the gas-liquid two-phase through the diversion-type spiral blades , so that the liquid phase is forced to distribute on the tube wall to form a liquid film. Since the measurement system uses multiple sets of helical blades, the spinning effect is remarkable.

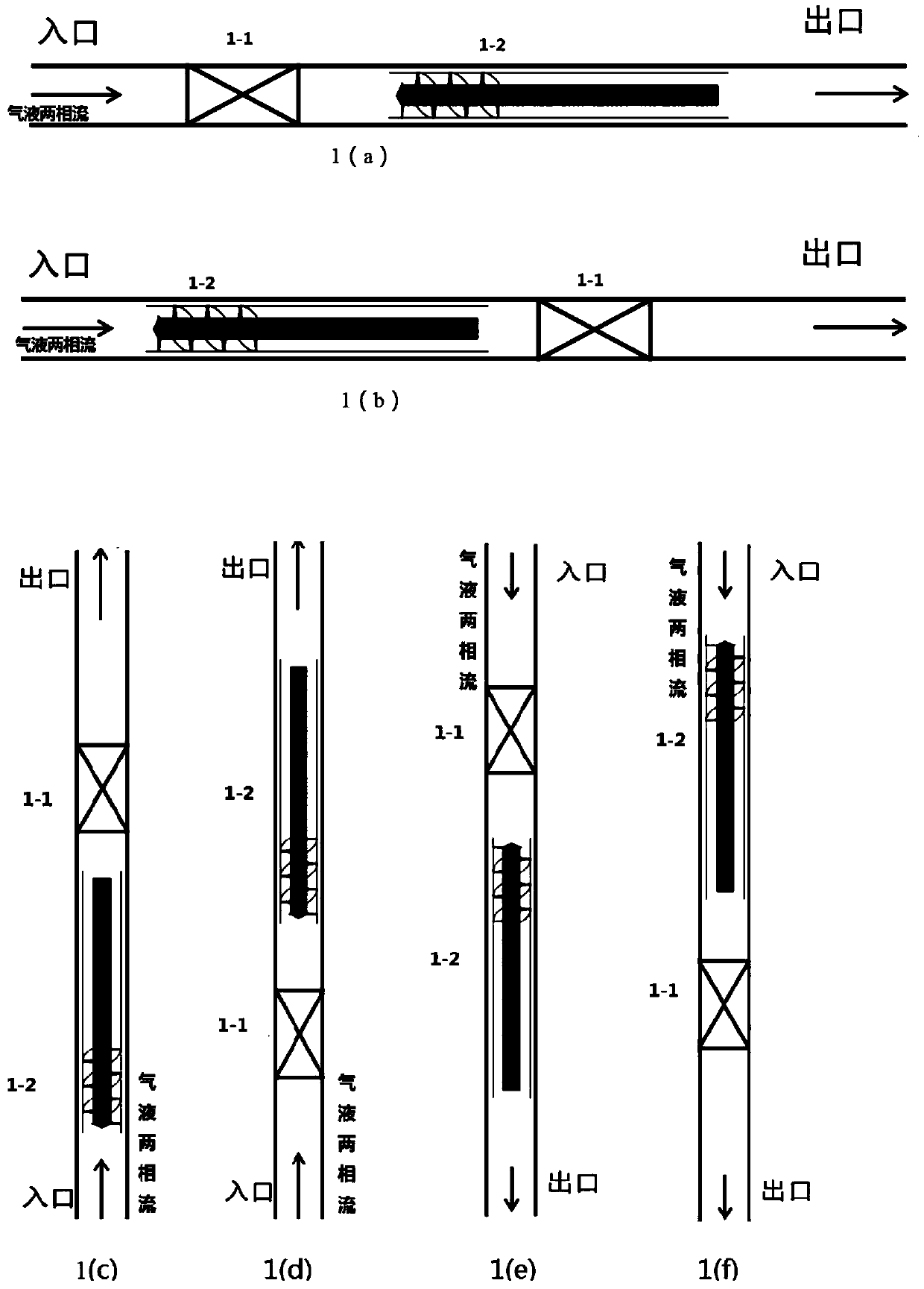

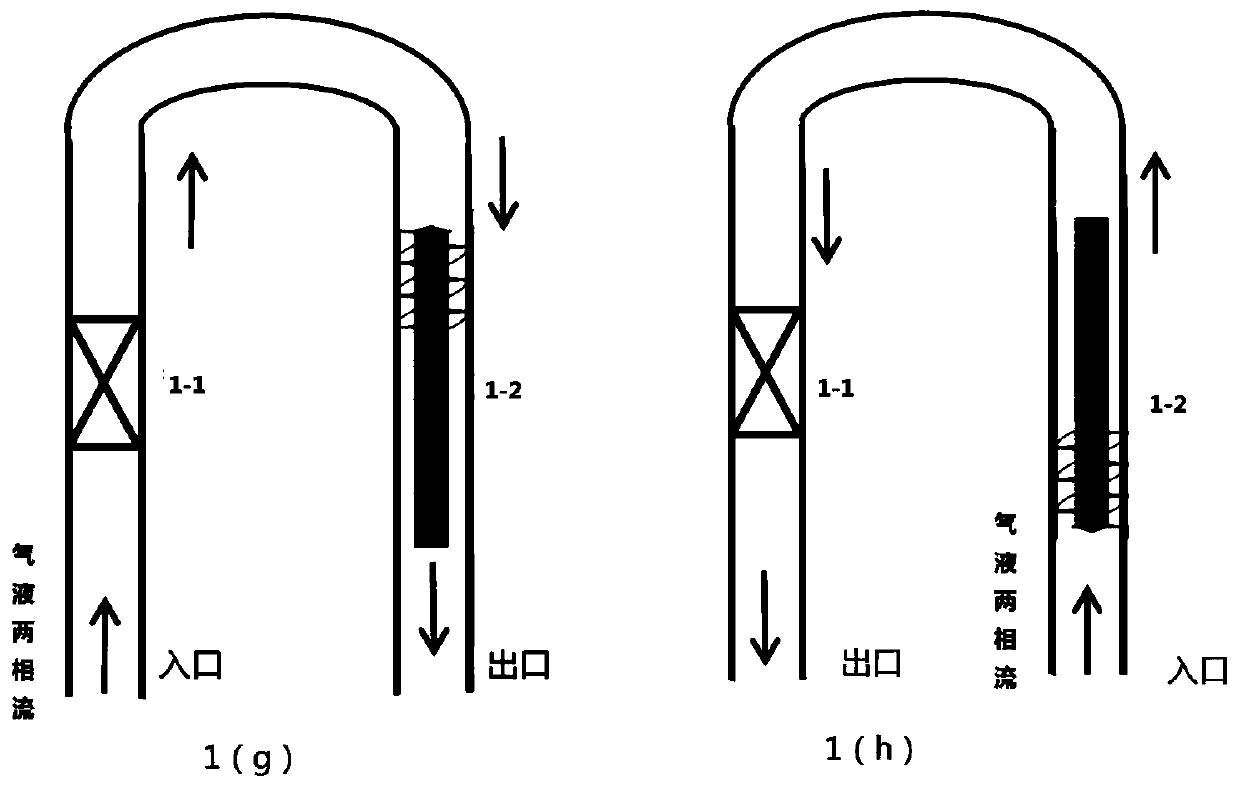

[0031] Such as figure 1 As shown, it is a schematic diagram of the installation method of the flow system for measuring the gas-liquid two-phase flow rate combined with the differential pressure method throttling device and the swirl phase separation capacitance water content method device involved in the present invention. The measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com