Method and device for measuring the reflectivity of a heliostat

A measurement method, heliostat technology, applied in the direction of scattering characteristics measurement, color/spectral characteristics measurement, etc., can solve the problems affecting the design and operation of solar power plants, and the measurement deviation of heliostat reflectivity, so as to achieve no dependence on light source, measurement Precise, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

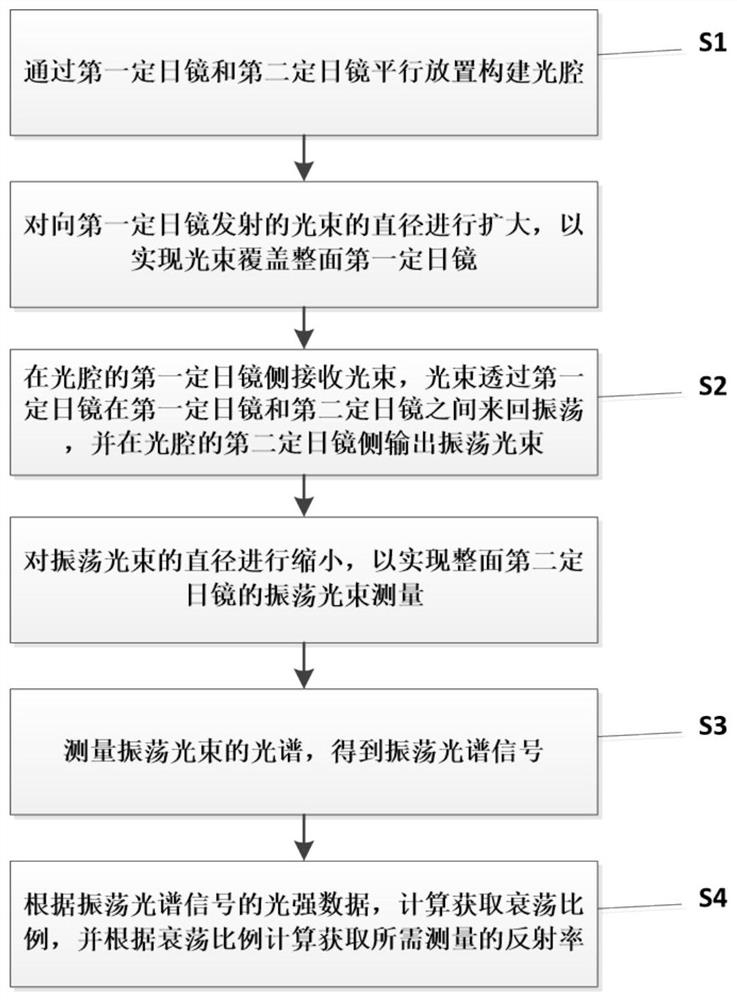

[0043] see figure 1 , the present embodiment provides a method for measuring the reflectivity of a heliostat, comprising the following steps:

[0044] S1: constructing an optical cavity by placing the first heliostat and the second heliostat in parallel;

[0045] S2: The light beam is received on the first heliostat side of the optical cavity, the light beam passes through the first heliostat and oscillates back and forth between the first heliostat and the second heliostat, and oscillates on the second heliostat of the optical cavity Side output oscillating beam;

[0046] S3: measuring the spectrum of the oscillating beam to obtain an oscillating spectrum signal;

[0047] S4: Calculate and obtain the ring-down ratio according to the light intensity data of the oscillation spectrum signal, and calculate and obtain the reflectance to be measured according to the ring-down ratio.

[0048] Now specifically describe this implementation in detail:

[0049]Specifically, the lig...

Embodiment 2

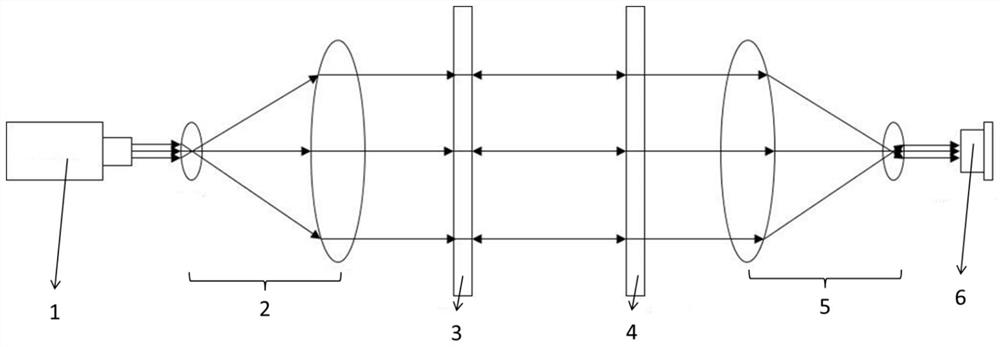

[0077] see figure 2 , the present embodiment provides a heliostat reflectivity measurement device based on Embodiment 1, including: a pulsed light source 1, a beam expander module 2, an optical cavity, a beam shrinker module 5, a spectrum receiving module 6, and a data processing module;

[0078] The beam expansion module 2 is used to expand the diameter of the original beam emitted by the pulse light source 1, and output the expanded beam;

[0079] The optical cavity includes a first heliostat 3 and a second heliostat 4 arranged parallel to each other. The optical cavity is used for the back-and-forth oscillation of the beam, wherein the optical cavity receives the expanded beam on the side of the first heliostat 3, and the expanded beam Through the first heliostat 3, oscillate back and forth between the first heliostat 3 and the second heliostat 4, and output the oscillating beam on the side of the second heliostat 4, wherein the expanded beam covers the first heliostat mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com