Multilayer electronic part and method for producing the same

A technology of electronic components and multi-layer bodies, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve problems such as low pass rate, unstable size, and performance fluctuations, and achieve reduction Effects of performance fluctuation, elimination of terminal electrode distance fluctuation, and improvement of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

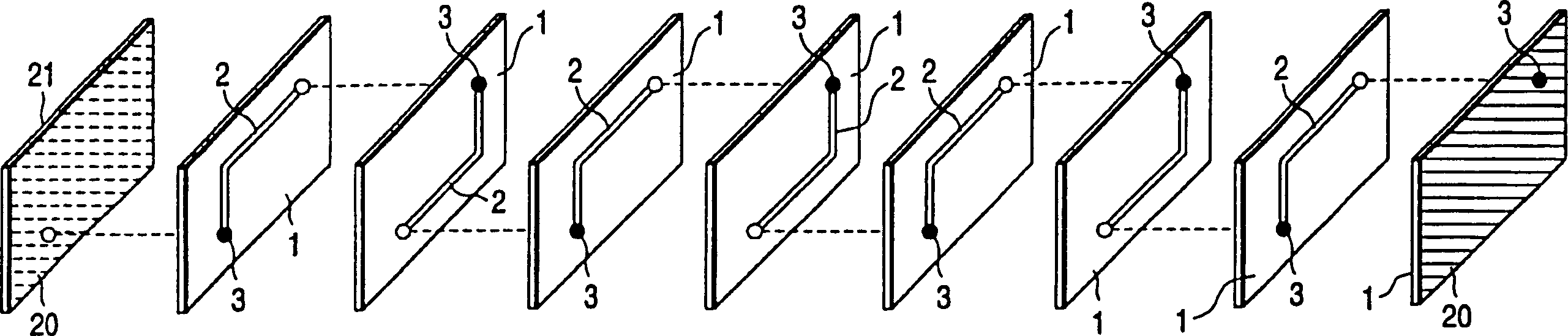

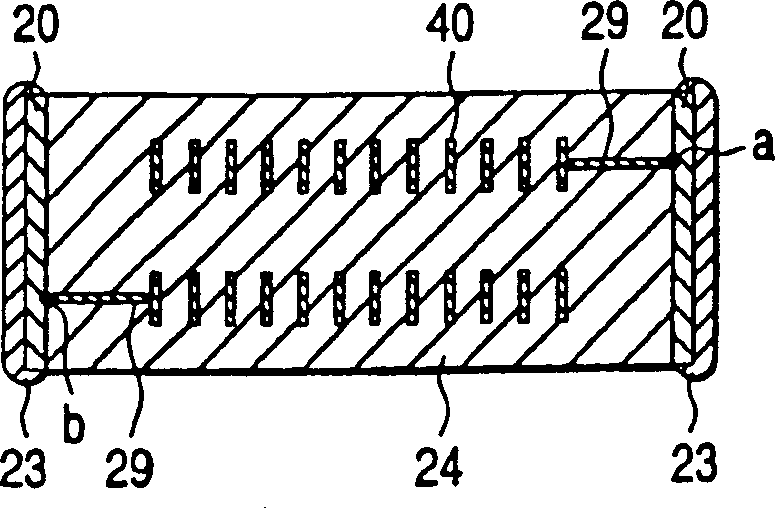

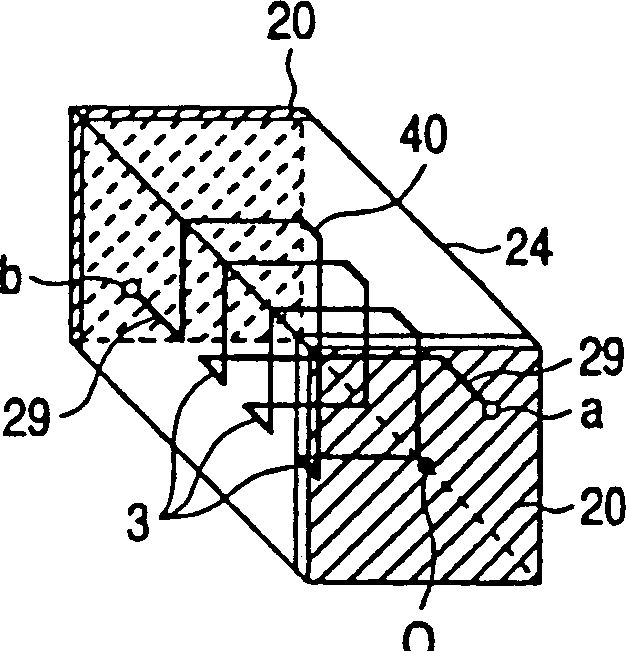

[0042] Figure 1A It is a perspective view corresponding to the layer structure of a chip as an embodiment of the electronic component of the present invention; Figure 1B with 1C are the cross-sectional and perspective views of the fabricated electronic components, respectively, Figure 1D is a plan view of electronic components mounted on a printed circuit board. figure 2 is a perspective view of the layer structure used to fabricate a plurality of chips of this embodiment. Figure 3A Perspective view of an assembly of stacked sheets. by Figure 1A Based on the layer structure shown, this embodiment of the electronic component was fabricated as follows.

[0043] A U (3 / 4 turn) or L (1 / 2 turn) shaped coil conductor 2 made of, for example, silver or silver alloy is printed on a green board 1 made of low magnetic permeability non-magnetic material. Form through hole 3 in each green board of these green boards 1 again, as Figure 1A As shown, the end of the coil conducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com