A Frequency Conversion Asynchronous Cavity Structure

A cavity structure, non-tuning technology, used in magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problem of increasing the acceleration gradient of the cavity, the large voltage gap between the short-circuit terminal and the open-circuit terminal of the cavity, and the increase of the cavity power loss, etc. problems, to achieve the effect of increasing the working voltage and acceleration gradient, increasing the working voltage gradient, and ensuring the temperature and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to more clearly understand the objects, features and advantages of the present invention. It should be understood that the embodiments shown in the accompanying drawings are not intended to limit the scope of the present invention, but are only intended to illustrate the essential spirit of the technical solutions of the present invention.

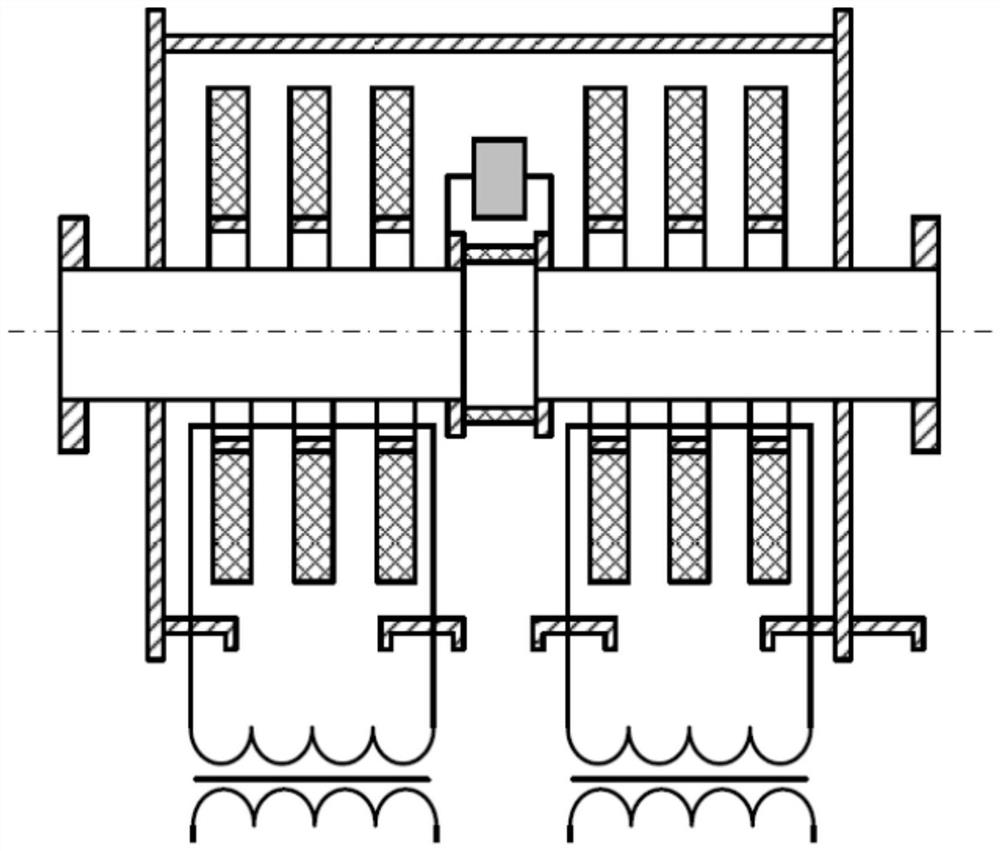

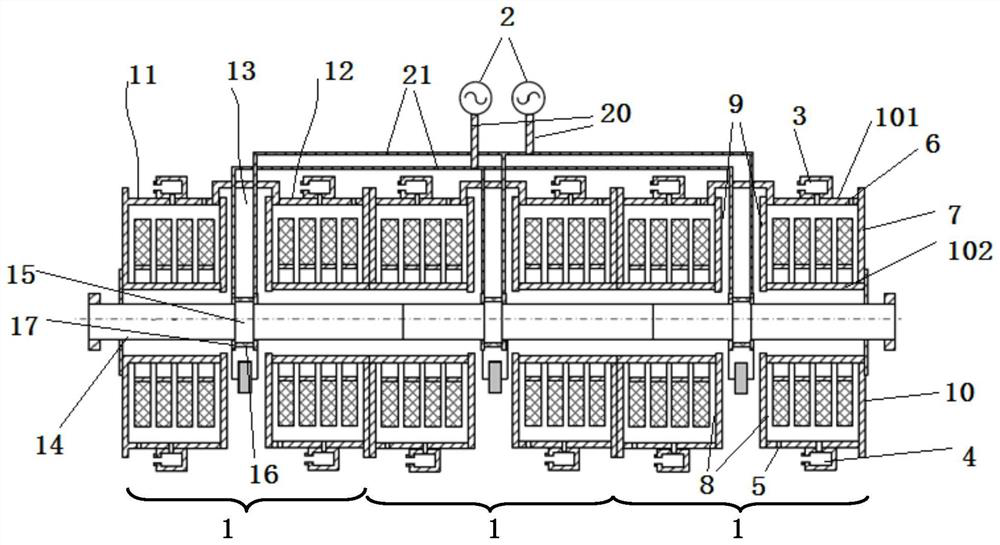

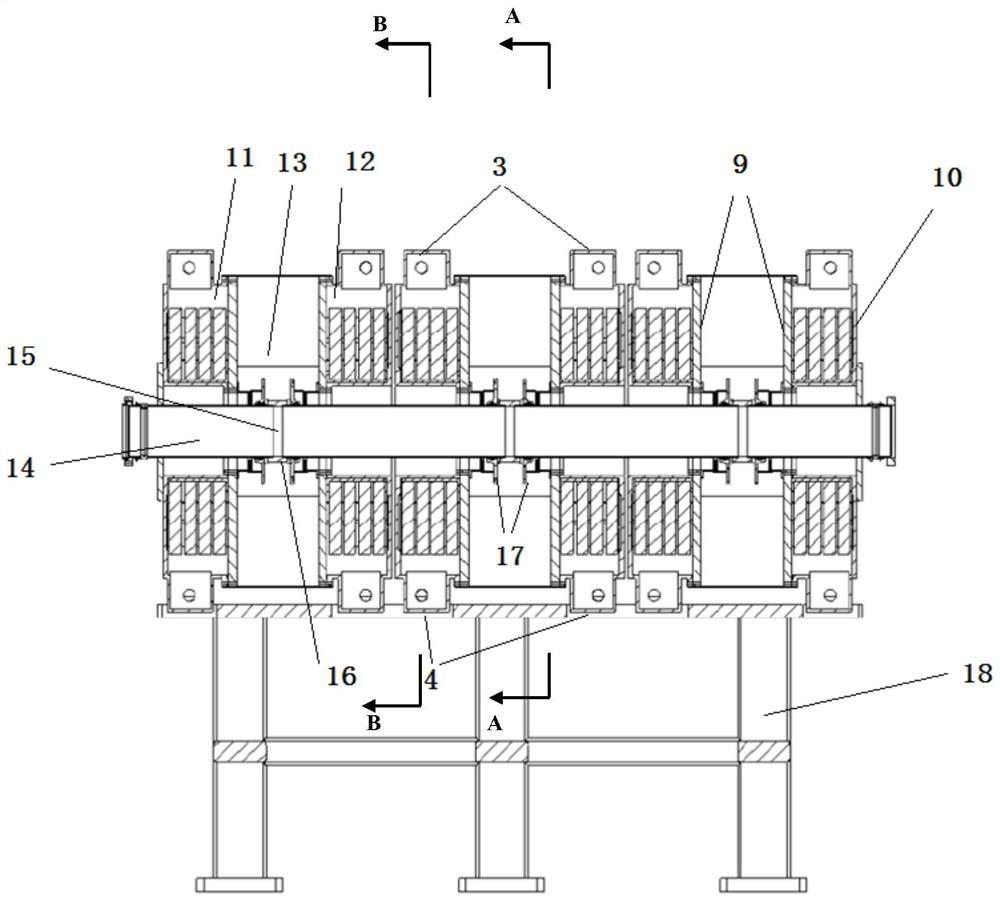

[0034] like Figures 2 to 6 As shown, the present invention provides a frequency conversion non-tunable cavity structure, which includes: at least two basic coaxial resonant cavity units 1 arranged in sequence; each basic coaxial resonant cavity unit 1 includes a resonant cavity 11 connected in a coaxial manner and the resonant cavity 12, and the acceleration gap 13 arranged coaxially between the resonant cavity 11 and the resonant cavity 12; The flow pipe 14 and the beam pipe 14 in the resonant cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com