High-protein-content compound flour and preparation method thereof

A compound flour and high-protein technology, which is applied in the direction of food ingredients as taste improvers, grain processing, and the function of food ingredients, etc., can solve the problems of long time consumption, poor taste, complicated preparation methods, etc., and achieve uniform distribution and high gluten. , pink pure and natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A high-protein content compound flour is prepared from the following raw materials by weight: 150 parts of wheat, 25 parts of soybean protein, 30 parts of walnut protein, 5 parts of cocoa powder, 50 parts of red dates, 15 parts of red beans, 5 parts of butter, and 3 parts of modified agent;

[0048] The high-protein compound flour is made as follows:

[0049] Step S1, the red dates are washed and pitted, baked at 70° C. to a water content of 10%, and ground to make red dates powder with a particle size of 100 meshes;

[0050] Step S2, roasting the red bean at 150° C. for 5min, grinding, and making the red bean powder with a granularity of 100 meshes;

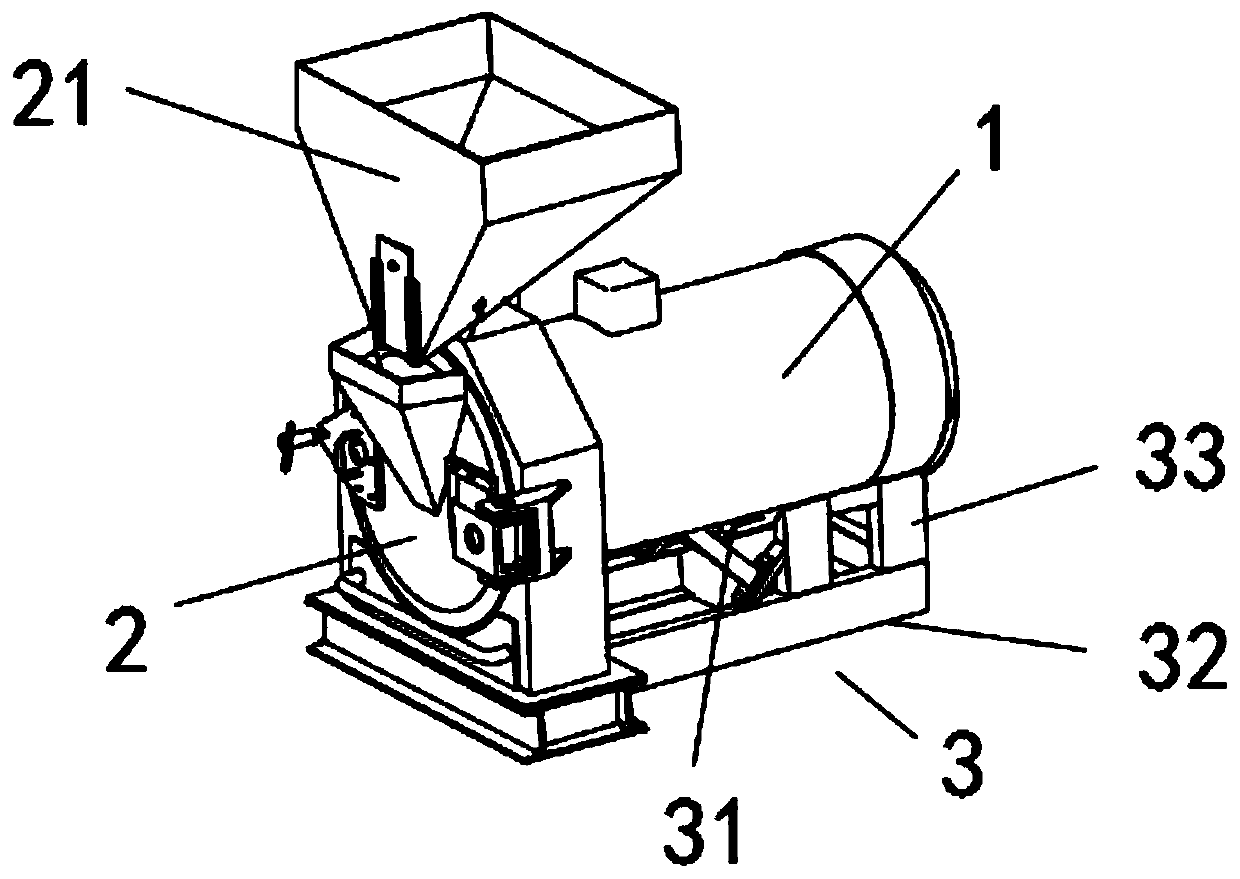

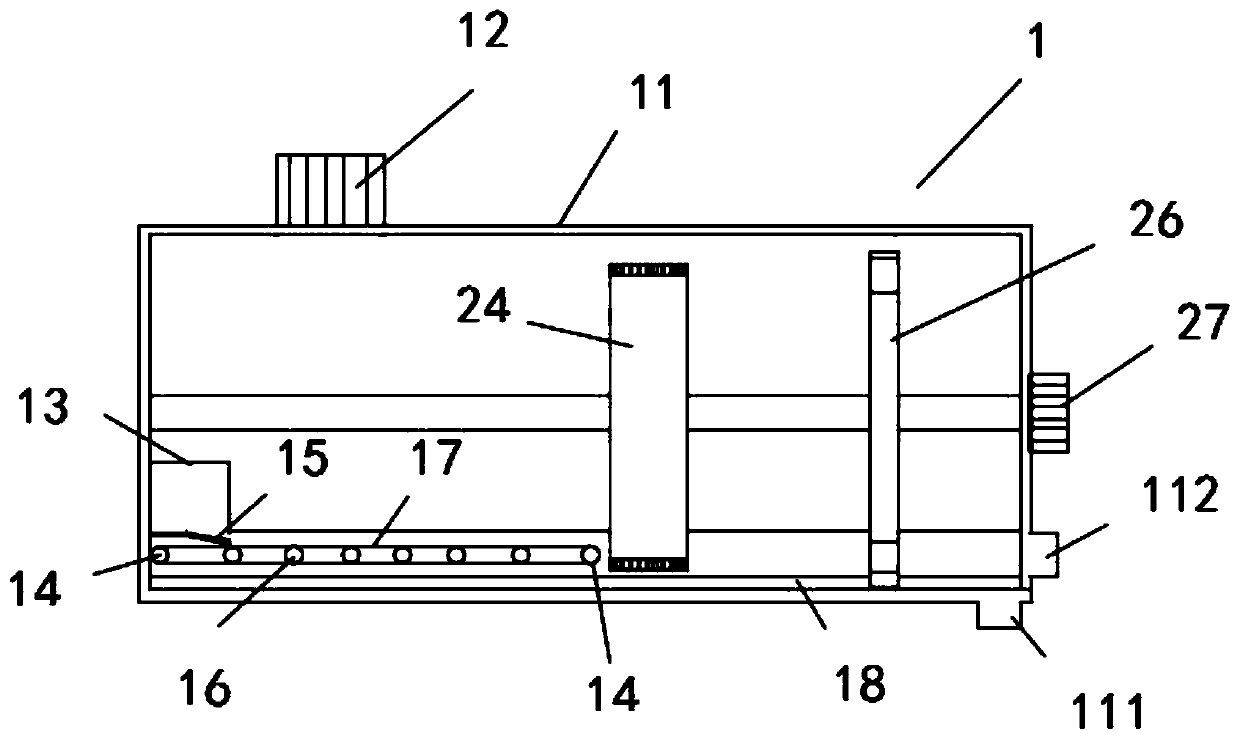

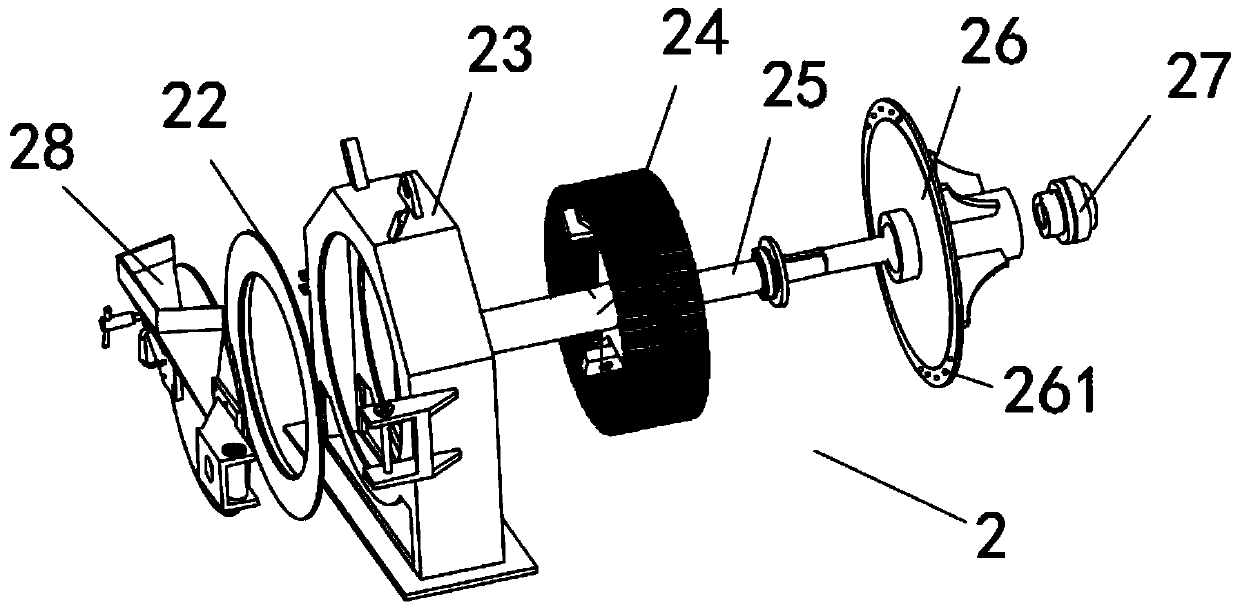

[0051] In step S3, the wheat is ground by the wheat grinding device, and the specific steps are as follows:

[0052] The first step, turn on the second motor, the transmission rod rotates, drives the fine grinding ring to rotate, adjust the cone, turn the two ends of the cone without the shell discharge hole into the in...

Embodiment 2

[0060] A compound flour with high protein content is prepared from the following raw materials by weight: 160 parts of wheat, 30 parts of soybean protein, 35 parts of walnut protein, 8 parts of cocoa powder, 55 parts of red dates, 20 parts of red beans, 8 parts of butter, and 3 parts of modified agent;

[0061] The high-protein compound flour is made as follows:

[0062] Step S1, the red dates are washed and pitted, baked at 70° C. to a water content of 10%, and ground to make red dates powder with a particle size of 100 meshes;

[0063] Step S2, roasting the red bean at 150° C. for 5min, grinding, and making the red bean powder with a granularity of 100 meshes;

[0064] In step S3, the wheat is ground by the wheat grinding device, and the specific steps are as follows:

[0065] The first step, turn on the second motor, the transmission rod rotates, drives the fine grinding ring to rotate, adjust the cone, turn the two ends of the cone without the shell discharge hole into t...

Embodiment 3

[0069] A high-protein content compound flour is prepared from the following raw materials by weight: 150-200 parts of wheat, 25-50 parts of soybean protein, 30-50 parts of walnut protein, 5-15 parts of cocoa powder, 50-70 parts of red dates, 15 parts of -30 parts red beans, 5-15 parts butter, 3-5 parts improver;

[0070] The high-protein compound flour is made as follows:

[0071] Step S1, the red dates are washed and pitted, baked at 70° C. to a water content of 10%, and ground to make red dates powder with a particle size of 100 meshes;

[0072] Step S2, roasting the red bean at 150° C. for 5min, grinding, and making the red bean powder with a granularity of 100 meshes;

[0073] In step S3, the wheat is ground by the wheat grinding device, and the specific steps are as follows:

[0074] The first step, turn on the second motor, the transmission rod rotates, drives the fine grinding ring to rotate, adjust the cone, turn the two ends of the cone without the shell discharge h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com