Antibacterial stainless steel composite powder, antibacterial stainless steel and preparation method thereof

An antibacterial stainless steel and composite powder technology, applied in the field of antibacterial stainless steel composite powder, antibacterial stainless steel and its preparation field, can solve the problems of insufficient antibacterial performance of stainless steel, uneven distribution of silver phase, poor antibacterial performance, etc., and achieve the cost of manufacturing and use. Low, uniform distribution of silver phase, the effect of improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

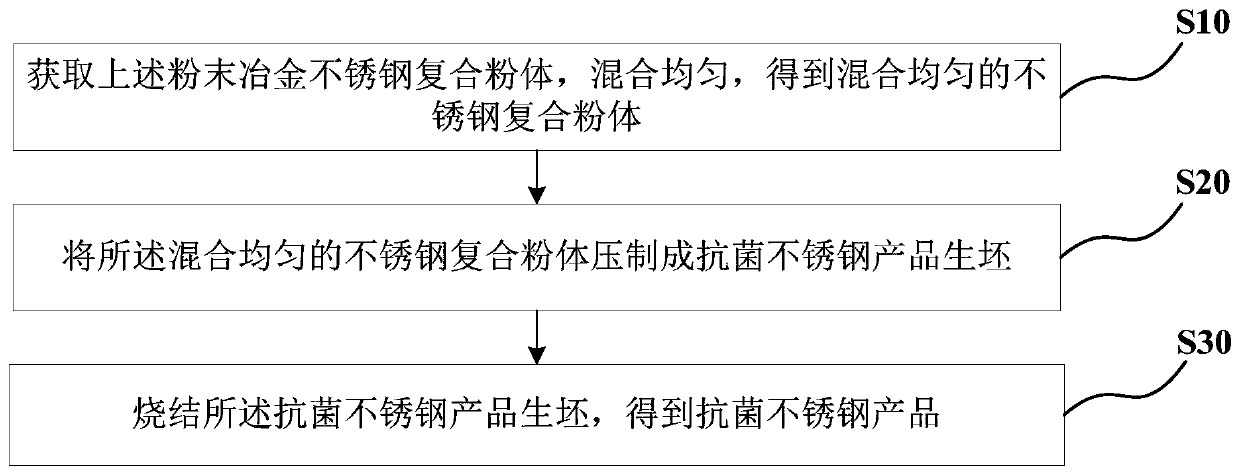

[0047] as attached figure 1 Shown, the embodiment of the present invention also provides a kind of preparation method of antibacterial stainless steel, comprises the following steps:

[0048] S10. Obtain the formula amount of the above-mentioned antibacterial stainless steel composite powder, and mix uniformly to obtain a uniformly mixed antibacterial stainless steel composite powder;

[0049] S20. Pressing the uniformly mixed antibacterial stainless steel composite powder into an antibacterial stainless steel product green body;

[0050] S30. Sintering the green body of the antibacterial stainless steel product to obtain an antibacterial stainless steel product.

[0051] The preparation method of the antibacterial stainless steel provided by the embodiment of the present invention uses the above antibacterial stainless steel composite powder as a raw material, and the antibacterial stainless steel product can be obtained by mixing, pressing and sintering. Since the preparat...

Embodiment 1

[0072] Taking mass fraction as unit, choose 17 parts of particle diameter as D90=22um, purity is more than 99.5% chromium powder, 0.5 part is 500 nanometers away from particle diameter, nanoscale silver oxide powder with purity more than 99.5%, 82.5 parts of particle diameter are D90=22um, iron powder with a purity of more than 99.5%.

[0073] Put the prepared powder into the three-dimensional mixer and mix evenly. The mixed powder is then put into a mold and a green disc is produced under cold pressing.

[0074] Put the green body into the sintering furnace, and under the protection of nitrogen protective atmosphere, firstly keep it warm at 400°C for 30 minutes, so that the silver oxide will decompose and react to produce pure silver. Then continue to heat up to the sintering temperature of 1200° C., and sinter the product for 2 hours to obtain the initial product workpiece.

Embodiment 2

[0076] Taking mass fraction as unit, choose 17 parts of particle diameter as D90=22um, purity is more than 99.5% chromium powder, 0.5 part is 500 nanometers away from particle diameter, nanoscale silver oxide powder with purity more than 99.5%, 82.5 parts of particle diameter are D90=22um, iron powder with a purity of more than 99.5%.

[0077] Put the prepared powder into the three-dimensional mixer and mix evenly. The mixed powder is then put into a mold and cold pressed to produce a green door handle.

[0078] Put the green body into the sintering furnace, and under the protection of argon, first keep it warm at 400°C for 30 minutes, so that the silver oxide will decompose and react to produce pure silver. Then continue to heat up to the sintering temperature of 1200° C., and sinter the product for 2 hours to obtain the initial product workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com