Dust removing mechanism used in machining process of foam milling machine

A milling machine processing and foaming technology, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of polluted working environment and scattered debris, and achieve the effect of reliable operation, low cost and pollution elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

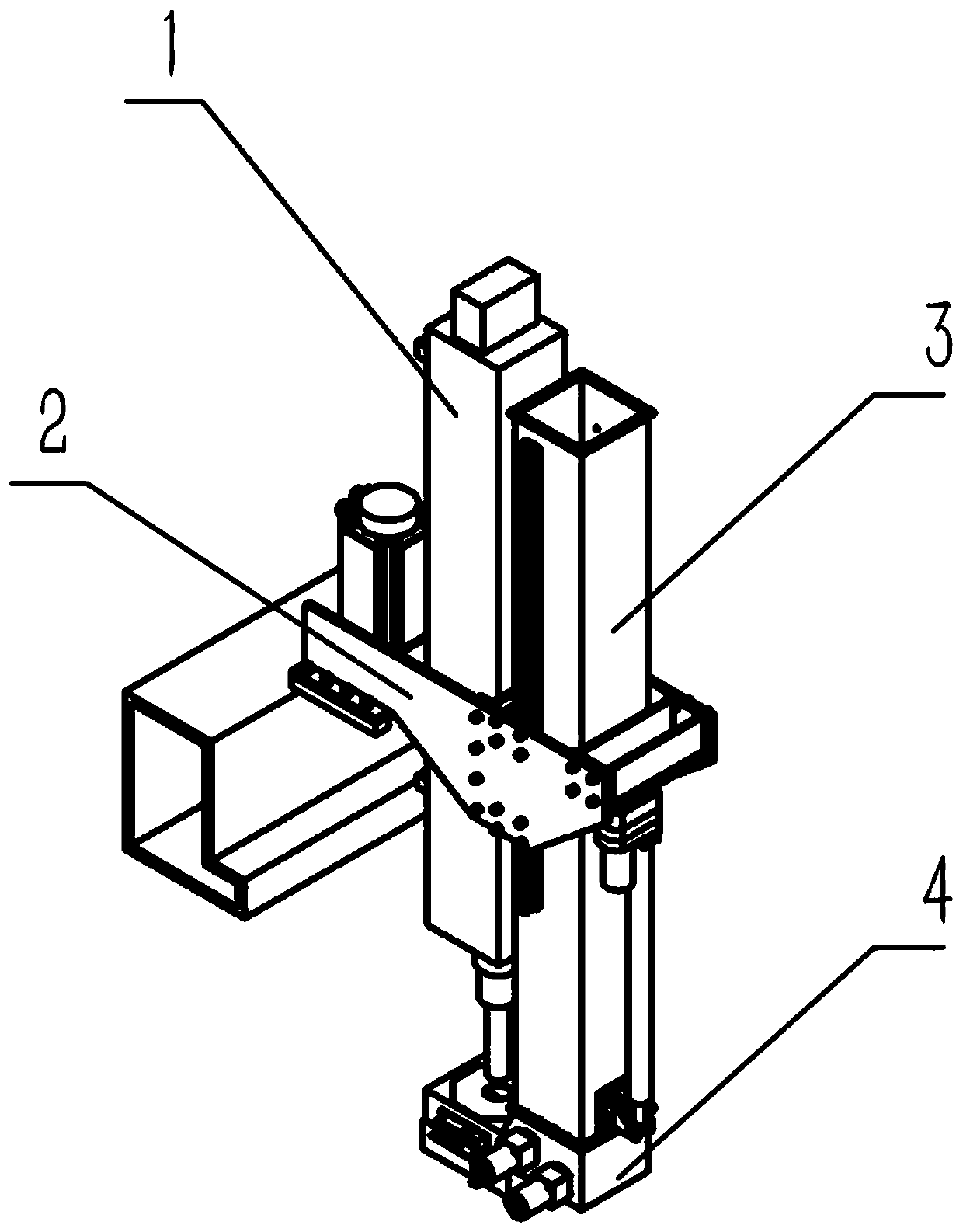

[0018] refer to figure 1 , The present invention is made up of mounting frame 2, lifting mechanism 3, dust suction crushing mechanism 4 and electric control system.

[0019] refer to figure 2 , wherein the mounting frame includes a left mounting plate 2-1 and a right mounting plate 2-2 fixed on the milling machine frame 1, a connecting plate 2-3 connecting the middle of the left and right mounting plates, and connecting the left and right mounting plates facing away from the end of the milling machine Electric push rod support plate 2-4, respectively installed in the left installation plate and the slide block 2-5 between the middle connecting plate 2-3 and the electric push rod support plate 2-4, in the inner side of the right installation plate,

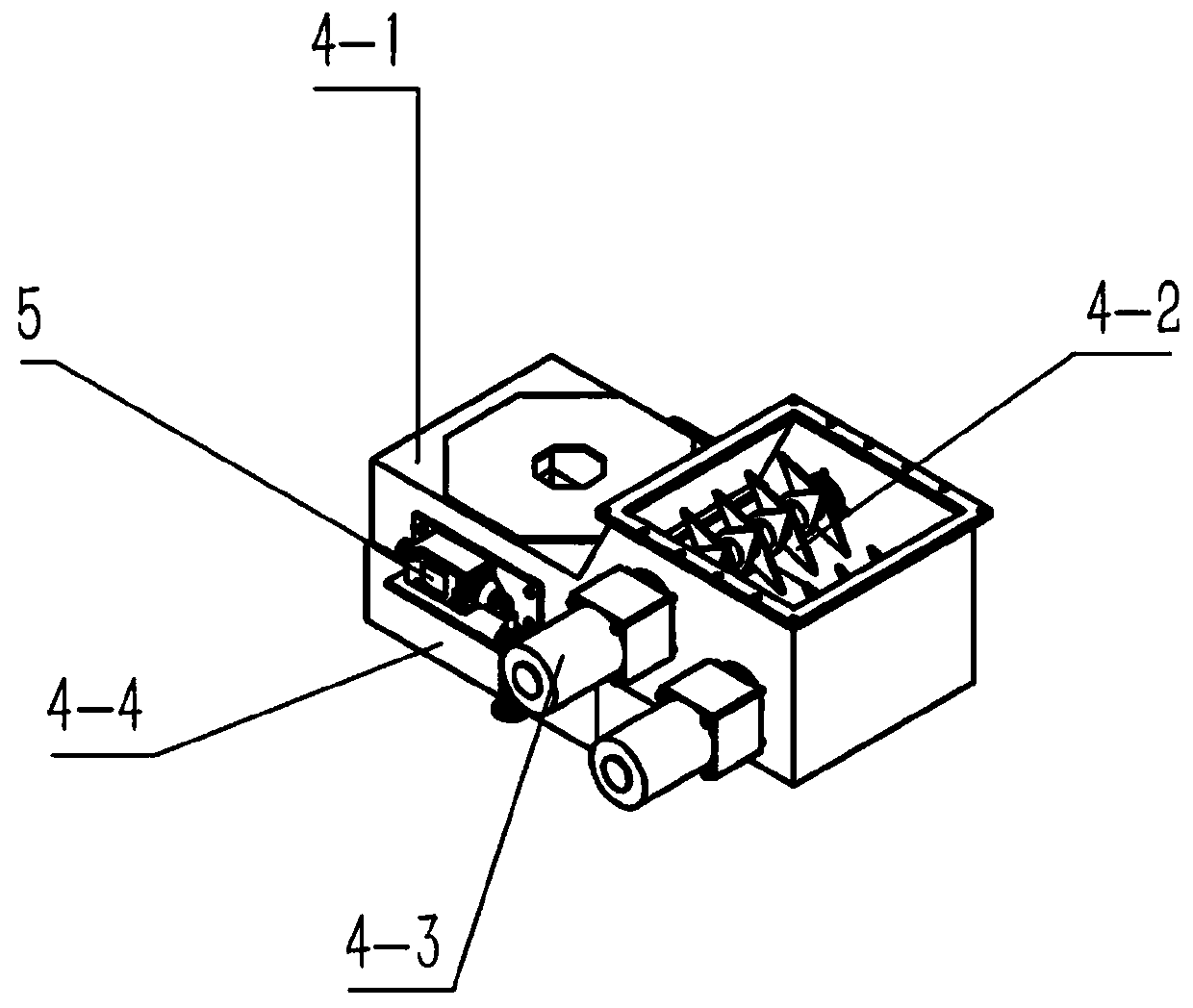

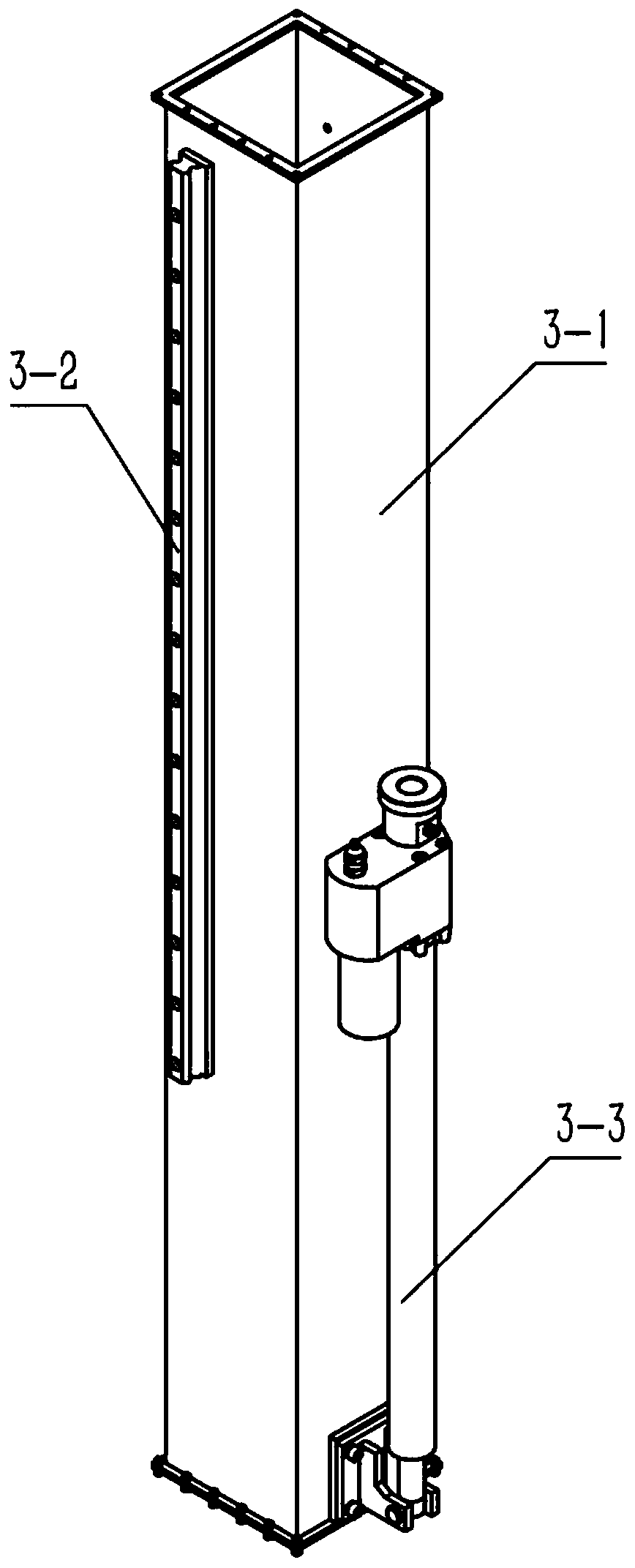

[0020] refer to image 3 , wherein the lifting mechanism includes a vertical cylindrical lifting rod 3-1, two linear slide rails 3-2 longitudinally fixed on both sides of the lifting rod, the slide rails cooperate with the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com