Automatic stacking equipment for urban buildings and working method of automatic stacking equipment

A technology of equipment and construction, applied in the field of automatic stacking equipment, can solve the problems of poor working ability and poor flexibility of stacking machinery, and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

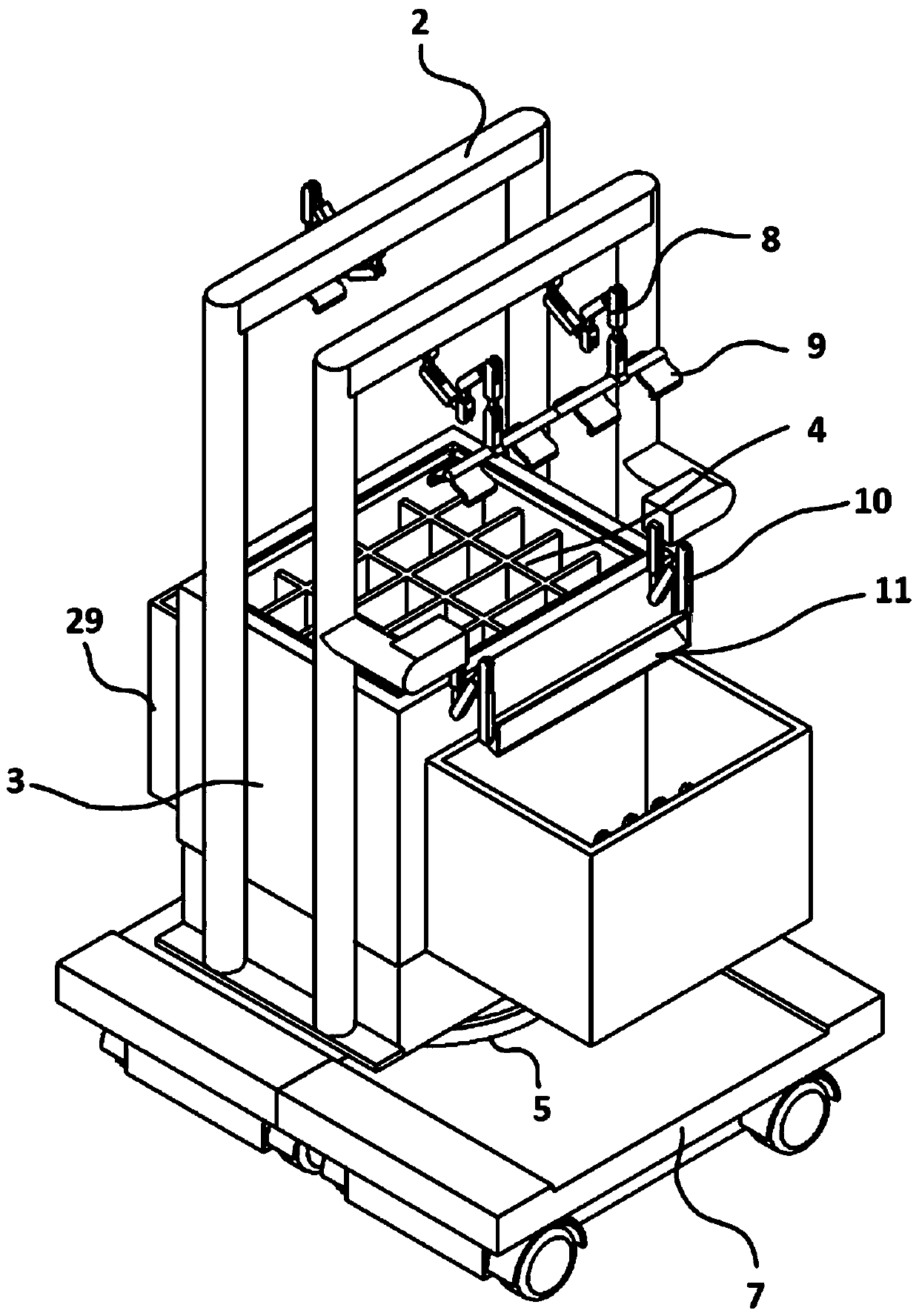

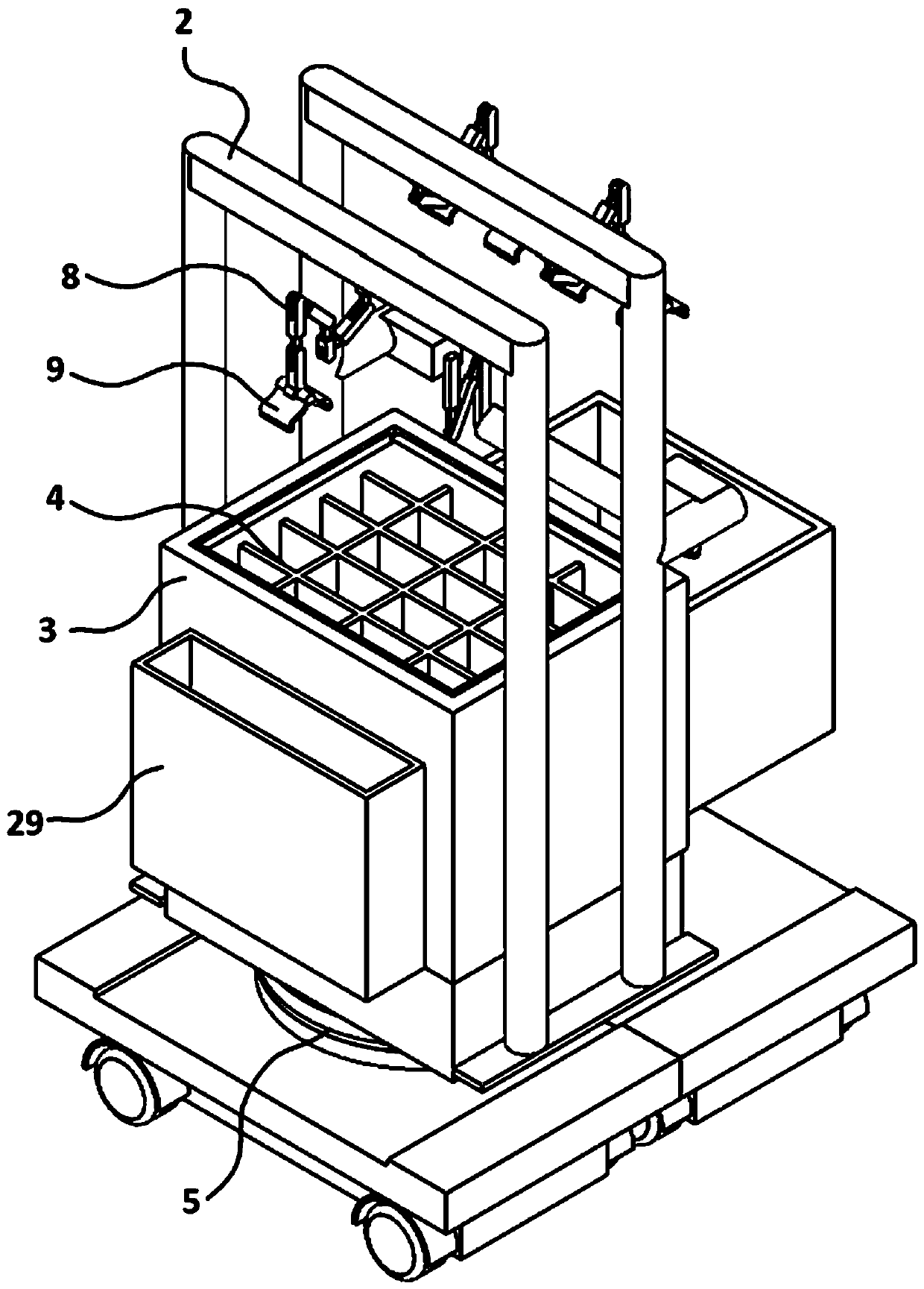

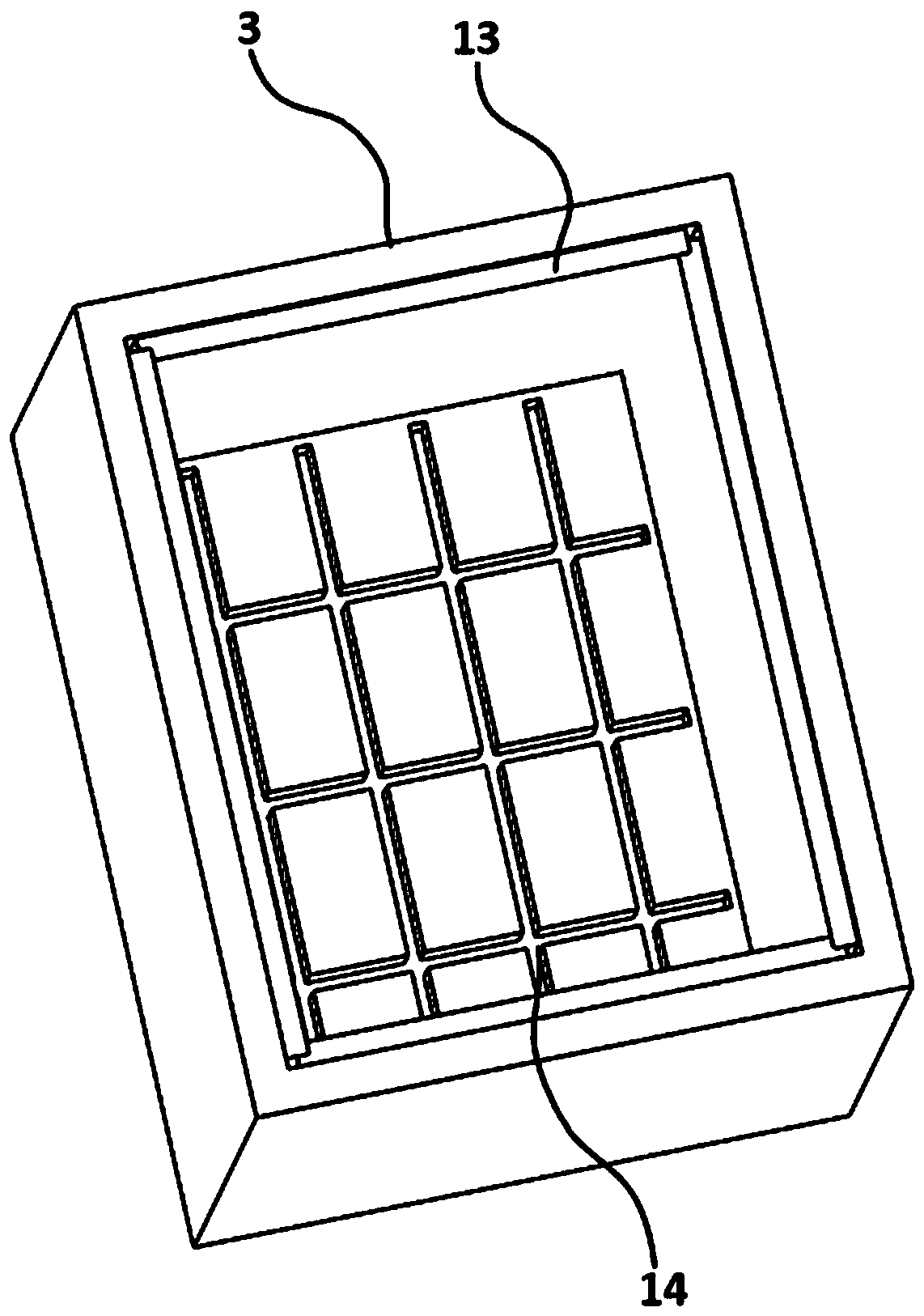

[0075] Such as Figure 1-14 As shown, this embodiment provides an automatic stacking device for urban buildings, including a stacking mechanism, a recycling mechanism, and a control mechanism.

[0076] The stacking mechanism includes a cement mixing device 1, a hanger 2, a main stacking device, an auxiliary stacking device, a dumping device, a brick storage room 3, a brick transfer device, a well-type partition device 4, a rotating chassis 5, a camera device 6 and a mobile device 7, The cement mixing device 1 is set in the cement mixing room, and includes the cement room, the lime room and the yellow sand room. The cement mixing device 1 is used to mix the cement, lime and yellow sand evenly according to the preset ratio; Above, the main stacking device and the auxiliary stacking device are respectively arranged on the front and rear sides of the hanger 2. The main stacking device includes a series electric clamp, and the series electric clamp includes a first curved outrigger...

Embodiment 2

[0094] Such as Figure 1-14 As shown, the present embodiment provides a working method for automatic stacking equipment for urban buildings, including the following working steps:

[0095] S101: Set the construction location, the navigation device generates the first navigation route from the current location to the construction location and sends it to the processing module 21, the processing module 21 outputs the first movement signal to the driving module 22, and the driving module 22 drives the mobile device 7 according to the first navigation route. A navigation route moves to the construction location.

[0096] S102: Add cement, lime and yellow sand into the cement mixing chamber according to a preset ratio, the processing module 21 outputs a mixing signal to the driving module 22, and the driving module 22 drives the cement mixing device 1 to start the preset time.

[0097] S103: The processing module 21 generates a stacking plan according to the design drawings, and t...

Embodiment 3

[0125] Such as Figure 1-14 As shown, in this embodiment, when using the brickwork method, the processing module 21 outputs a rotation signal to the driving module 22, and the driving module 22 drives the rotating chassis 5 to rotate 180 degrees.

[0126] The processing module 21 outputs the second brick fetching signal to the drive module 22, and the drive module 22 drives the first curved extension arm 8 of the auxiliary stacking device to drive the brick clamp 9 into the brick breaking chamber 29, and then drives the brick clamp 9 to clamp the broken bricks. bricks.

[0127] The processing module 21 outputs a squeeze signal to the driving module 22, and the driving module drives the first curved outrigger 8 to drive the brick gripper 9 to knead the broken bricks on the lime cement slurry.

[0128] Specifically, the main stacking device can stack multiple bricks at one time, and at the corner of the wall, when the number of bricks to be stacked is less than the number of br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com