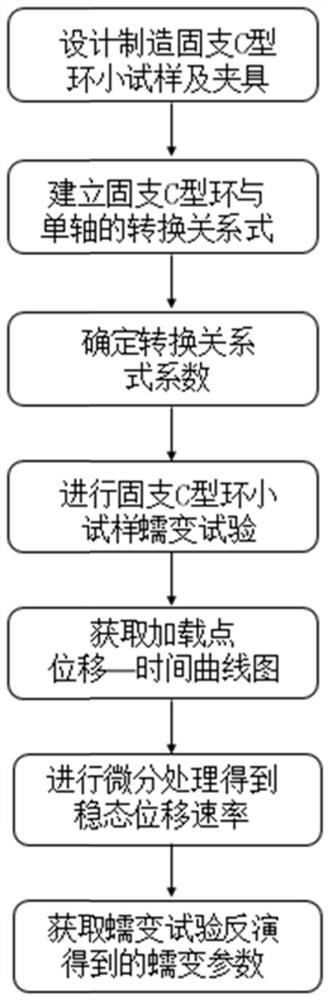

Method for Measuring Creep Mechanical Properties of Materials Using C-shaped Small Samples Supported

A small sample, creep technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problem of large deformation of the sample, and achieve large deformation and data The effect of small fluctuation and simple stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

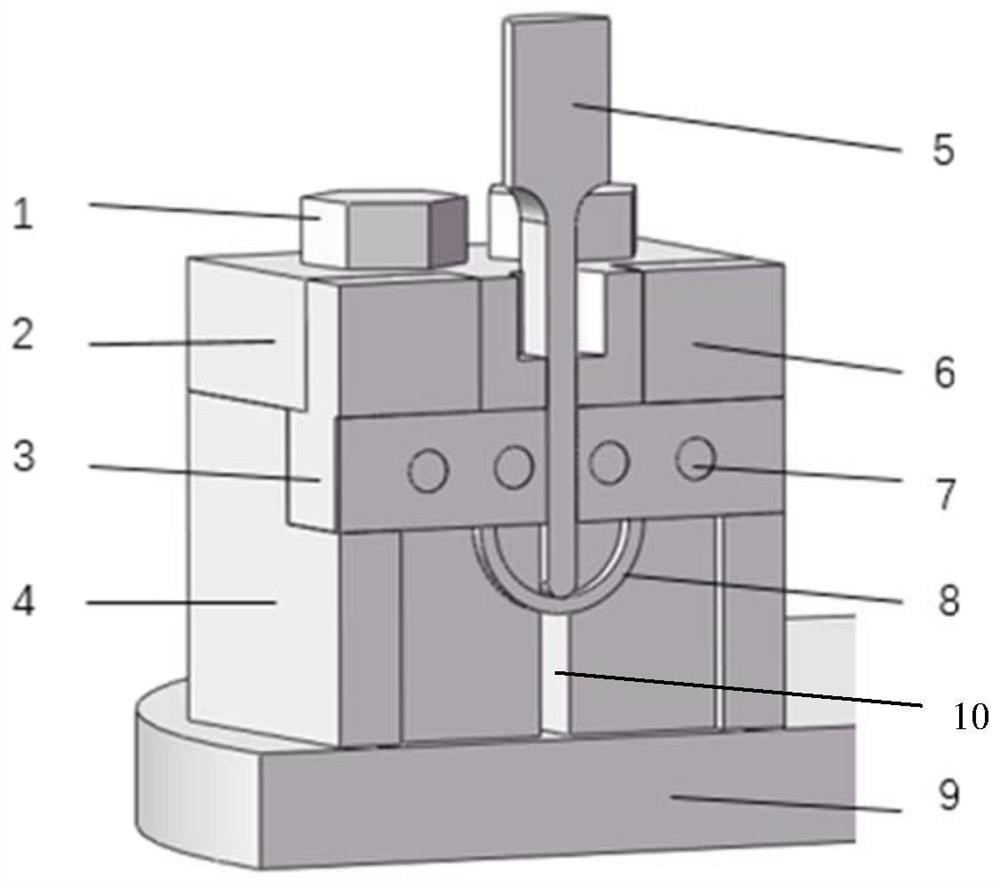

[0067] The material is 1.25Cr0.5MoSi, the four sets of load values of the fixed-support C-ring test are 40N, 43N, 46N and 49N respectively, the test temperature is 550°C, the cross-section of the sample is rectangular, the thickness is 1.2mm, and the inner radius 4.6mm, the outer radius is 5.4mm, and the length of the straight edge of the sample is 2mm. Using the method described in the technical solution of the present invention, the creep mechanical properties of the above-mentioned materials are measured:

[0068] 1. Design and manufacture a fixed C-ring small sample and fixture. The cross-section of the C-ring small sample is a rectangular section, the thickness is 1.2mm, the inner radius is 4.6mm, and the outer radius is 5.4mm. The straight edge length is 2mm.

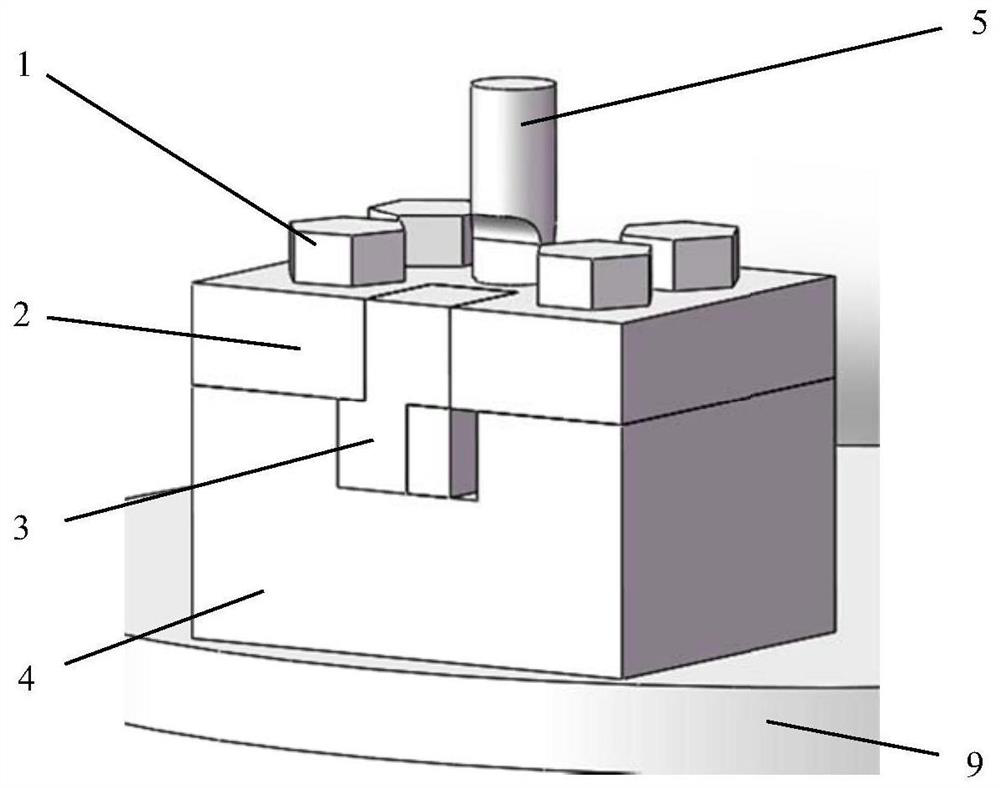

[0069] like Figure 2a and Figure 2b As shown in , the clamp is composed of an upper plate 2, a lower plate 4, a left baffle 3, a right baffle 6 and a disk 9.

[0070] Wherein, the upper plate 2, the lower p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com