Direct type optical projection system and optical projection method

A projection system and direct-type technology, applied in the field of optical projection system and optical projection, can solve problems such as inability to adapt, texture filling failure, large thermal resistance, etc., and achieve the effect of small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

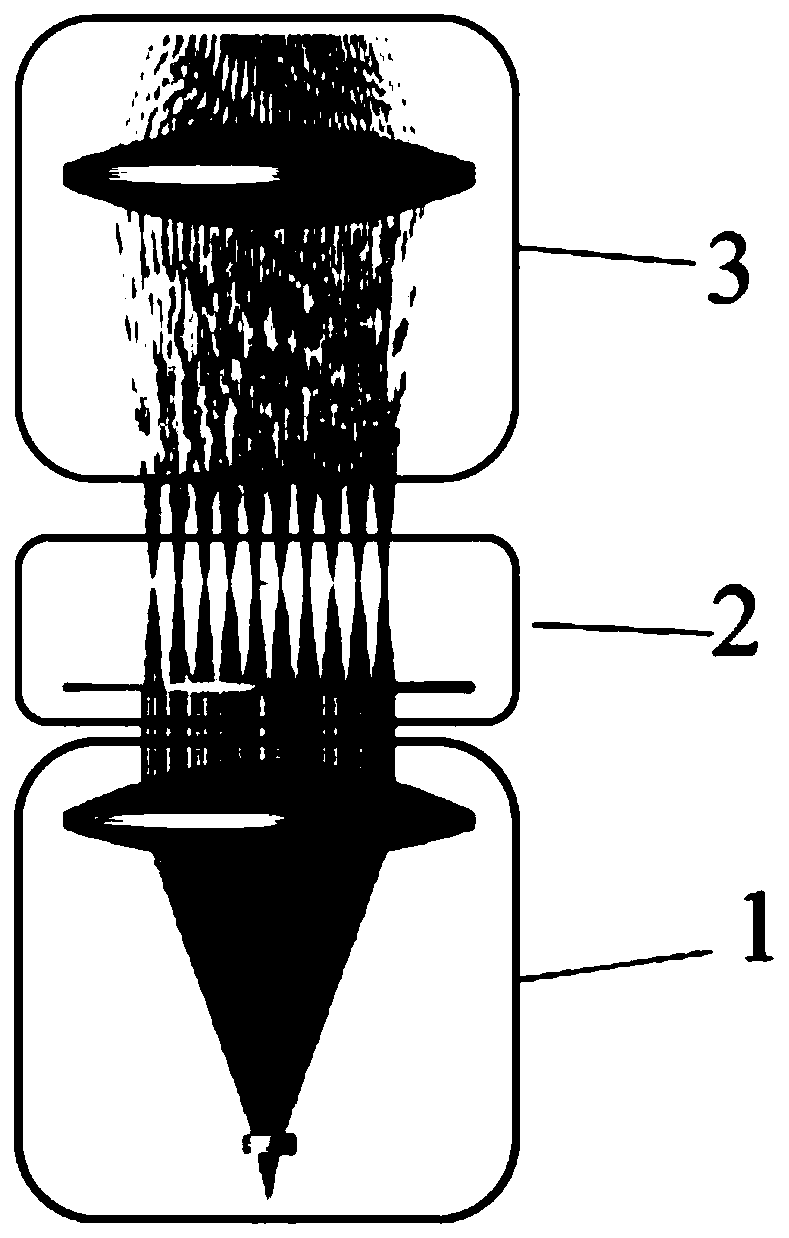

[0107] Such as Picture 10 As shown, in one embodiment of the present invention, the concave lens group 12 is composed of a concave lens, the incident surface of the concave lens near the light source is configured as a concave curved surface, and the exit surface of the concave lens on the side away from the light source is also configured as a concave Surface.

[0108] Picture 11 The structure of the single lens constituting the concave lens group in the direct type optical projection system of the present invention in another embodiment is schematically shown.

[0109] Such as Picture 11 As shown, in another embodiment of the present invention, the concave lens group 12 is still composed of a concave lens, but with Picture 10 The difference between the concave lens shown is that the exit surface of the concave lens away from the light source is configured as a plane.

[0110] Picture 12 The structure of the single lens constituting the concave lens group in the direct-type opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com