Package accommodating fluids

A packaging and fluid technology, applied in the direction of packaging, wrapping paper, transportation and packaging, etc., can solve the problems that jetting cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] The present invention will be described below with reference to examples.

[0100] The measurement methods and container bodies (bottles) performed in the following examples for measuring the corresponding characteristics and physical properties are described below.

[0101]

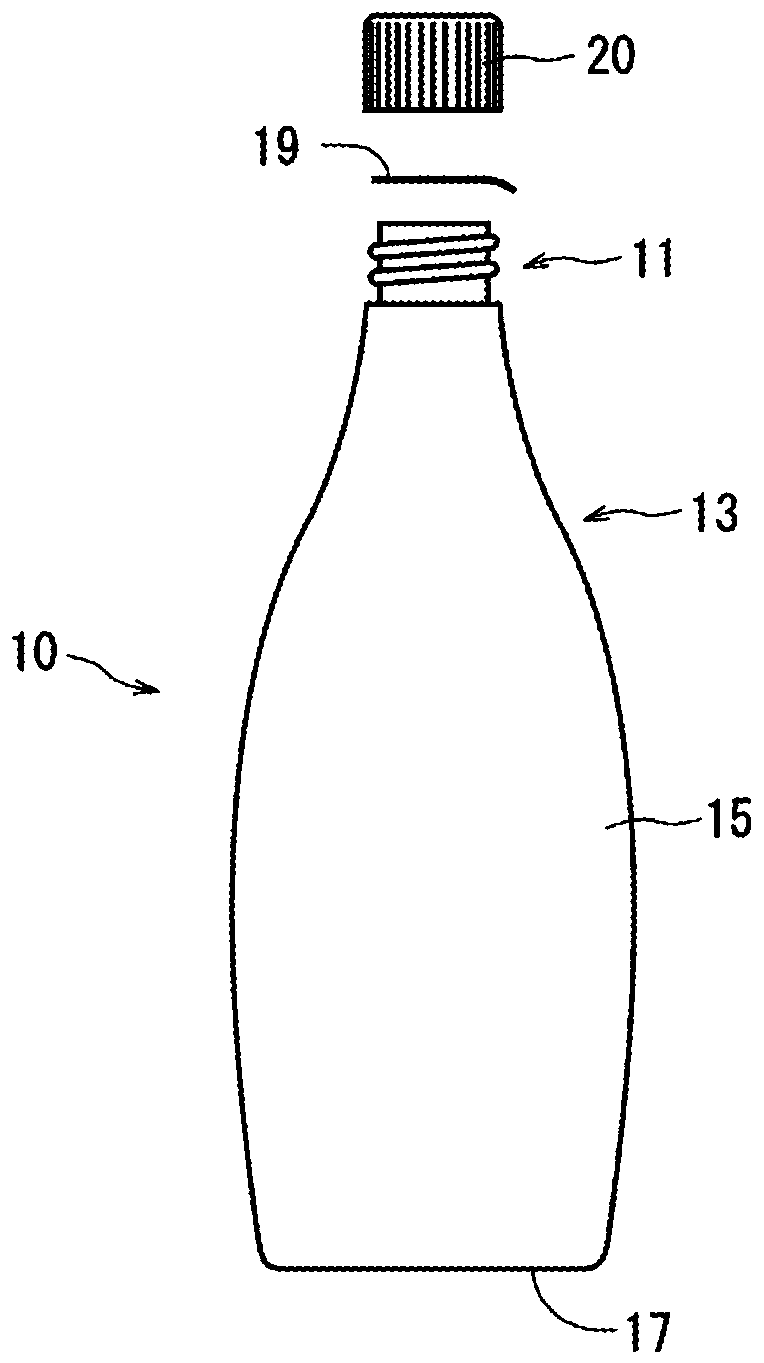

[0102] Multilayer direct blow molded bottles with the following layer composition and 500 mL capacity were formed by known methods and used in the following experiments.

[0103] Bottle A: Direct blow molded multilayer bottle with 5 types of 9 layers

[0104] Layer composition: inner layer / adhesive layer / liquid diffusion prevention layer / adhesive layer / main layer / adhesive layer / oxygen barrier layer / adhesive layer / outer layer

[0105] Inner layer: low density polyethylene

[0106] Adhesive layer: acid-modified polyethylene

[0107] Liquid diffusion prevention layer: Ethylene-vinyl alcohol copolymer (EVOH)

[0108] Main Layer: Low Density Polyethylene (LDPE)

experiment example 1

[0144] Bottle A (a direct blow-molded multilayer bottle with 5 types of 9 layers) was prepared as a container body.

[0145] Medium-chain fatty acid triglyceride as a lubricating liquid was applied to the inner surface of bottle A in the amount shown in Table 1 by an air-brush method. A bottle whose inner surface was coated with a lubricating liquid was used to form a pool of the aforementioned lubricating liquid, and was subjected to tests of slip properties with respect to fluid and peelability with respect to fluid. The results are shown in Table 1. Here, the contact angle of the lubricating liquid with respect to the low density polyethylene surface is smaller than the contact angle of the fluid with respect to the low density polyethylene surface.

experiment example 2

[0147] Slip property with respect to fluid and peelability with respect to fluid were tested in the same manner as in Experimental Example 1, except that a pool of lubricating liquid was not formed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com