Method of biologically synthesizing ZnxCd1-xS quantum dots by using zinc-cadmium wastewater as metal source

A biosynthesis and quantum dot technology, applied in the field of green technology, can solve the problems of large zinc and cadmium wastewater production, low recovery value, and high toxicity, and achieve low energy consumption, low cost, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

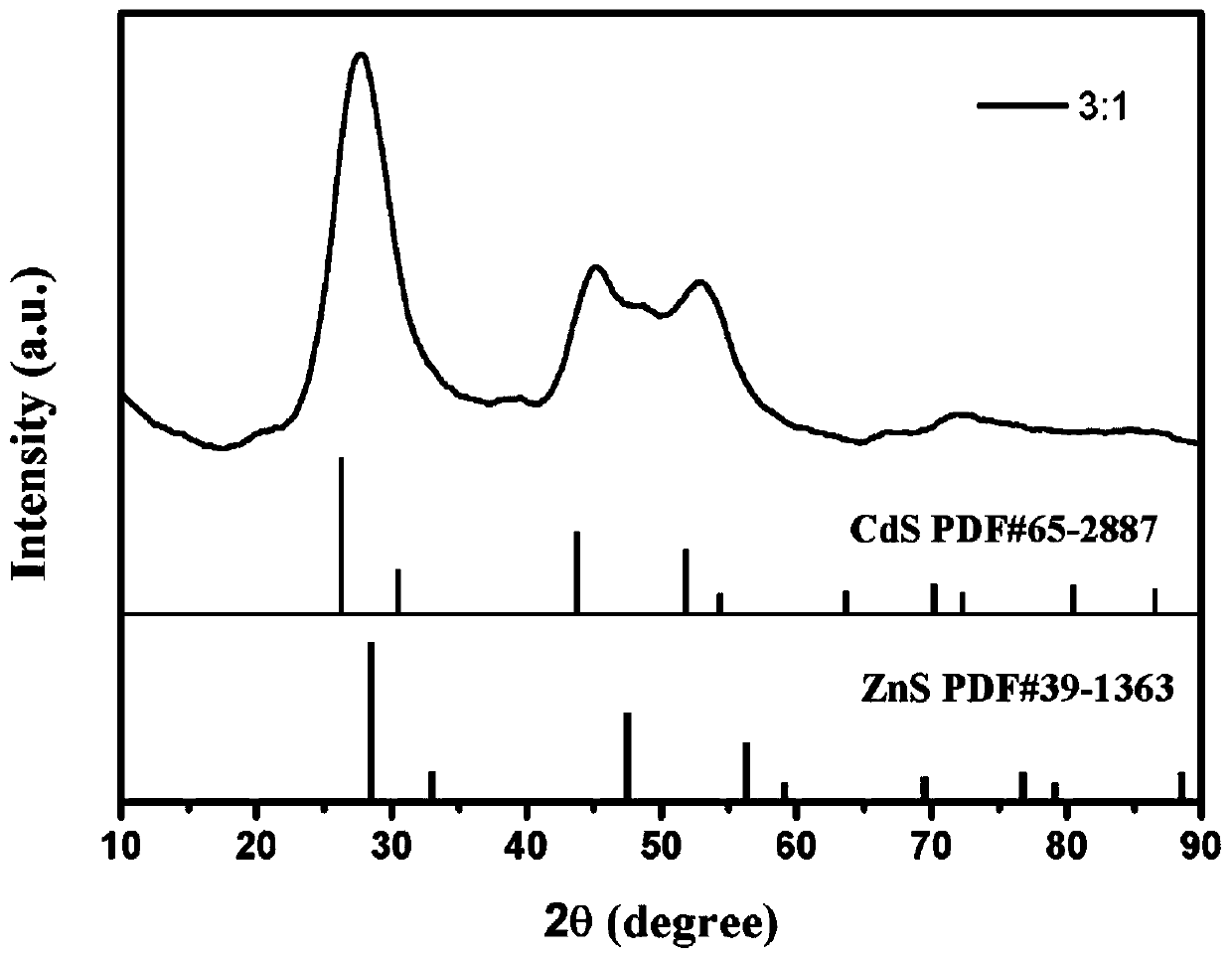

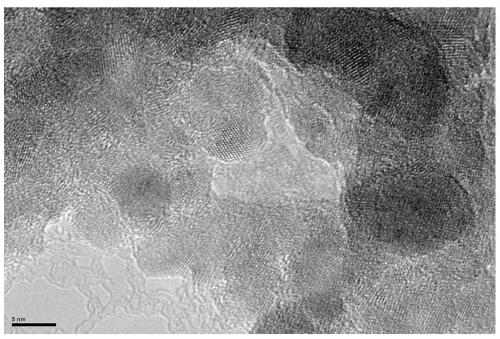

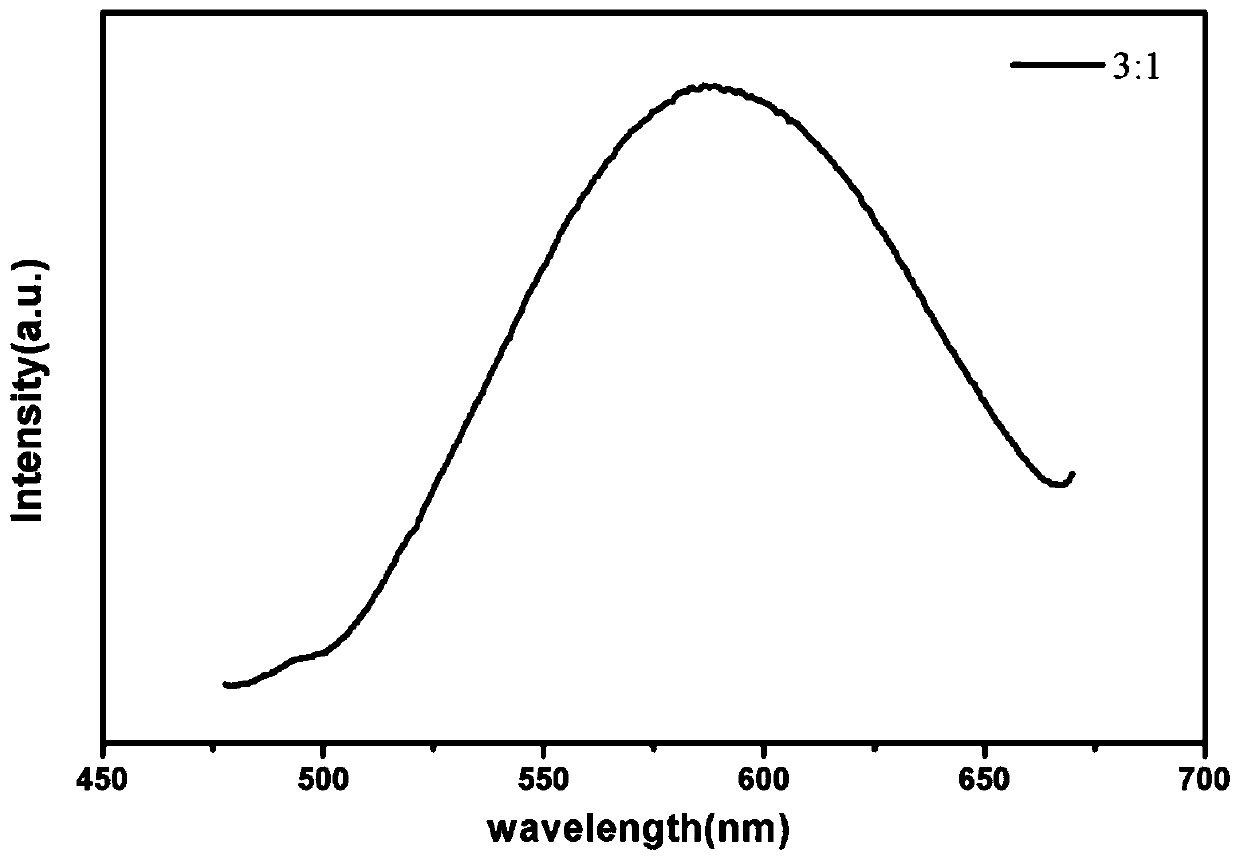

[0036] Example 1: Preparation of ZnCdS quantum dots from wastewater with Zn / Cd concentration ratio of 3:1

[0037] Step 1, the cultivation of sulfate-reducing bacteria

[0038] 1. The medium composition of sulfate reducing bacteria is: 0.2mol / L lactic acid, 14.28g / L Na 2 SO 4 , 1.0g / LNH 4 Cl, 0.5g / L KH 2 PO 4 , 0.5g / L MgSO 4 , 0.1g / L CaCl 2 , 0.5g / L yeast extract powder, pH7.0;

[0039] 2. Insert the sulfate-reducing bacteria into the culture medium of sulfate-reducing bacteria, and put them into anaerobic culture at 37°C. Transplant once every 20 days according to the volume ratio of 25% (seed solution / medium).

[0040] Step 2, preparation of ZnCdS quantum dots

[0041] Adjust the pH of the zinc-cadmium wastewater to neutral, add the sulfate-reducing bacteria cultured for 5 days to the zinc-cadmium wastewater with a concentration ratio of Zn:Cd=3:1, mix well and let stand for 1-2h, and centrifuge the obtained product at 8000rpm for 5min to collect the precipitate. I...

Embodiment 2

[0042] Example 2: Preparation of ZnCdS quantum dots from wastewater with Zn / Cd concentration ratio of 5:1

[0043] Step 1, the cultivation of sulfate-reducing bacteria

[0044] 1. The medium composition of sulfate reducing bacteria is: 0.1mol / L lactic acid, 7.14g / L Na 2 SO 4 , 1.0g / LNH 4 Cl, 0.5g / L KH 2 PO 4 , 0.5g / L MgSO 4 , 0.1g / L CaCl 2 , 0.5g / L yeast extract powder, pH7.0;

[0045] 2. Insert the sulfate-reducing bacteria into the sulfate-reducing bacteria culture medium, and place it at 33° C. for anaerobic culture. Transplant once every 20 days according to the volume ratio of 20% (seed solution / medium).

[0046] Step 2, preparation of ZnCdS quantum dots

[0047] Adjust the pH of the zinc-cadmium wastewater to neutral, add the sulfate-reducing bacteria cultured for 6 days to the zinc-cadmium wastewater with a concentration ratio of Zn:Cd=5:1, mix well and let it stand for 1 hour, and centrifuge the obtained product at 6000rpm for 10min to collect the precipitate....

Embodiment 3

[0048] Embodiment 3: Zn / Cd concentration ratio 9:1 prepares ZnCdS quantum dot

[0049] Step 1, the cultivation of sulfate-reducing bacteria

[0050] 1. The medium composition of sulfate reducing bacteria is: 0.2mol / L lactic acid, 14.28g / L Na 2 SO 4 , 1.0g / LNH 4 Cl, 0.5g / L KH 2 PO 4 , 0.5g / L MgSO 4 , 0.1g / L CaCl 2 , 0.5g / L yeast extract powder, pH7.0;

[0051] 2. Insert the sulfate-reducing bacteria into the culture medium of sulfate-reducing bacteria, and place it at 35° C. for anaerobic culture. Transplant once every 20 days according to the volume ratio of 25% (seed solution / medium).

[0052] Step 2, preparation of ZnCdS quantum dots

[0053] Adjust the pH of the zinc-cadmium wastewater to neutral, add the sulfate-reducing bacteria cultured for 7 days to the zinc-cadmium wastewater with a concentration ratio of Zn:Cd=9:1, mix and let it stand for 1 hour, and collect the precipitate by centrifuging at 10,000 rpm for 5 minutes. It was dried at ℃, ground to powder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com