Method for improving toughness of zirconium alloy cladding material

A cladding material and zirconium alloy technology, which is applied in the fields of reactor fuel elements, climate sustainability, nuclear power generation, etc., can solve the problem of increasing the risk of damage to the zirconium alloy cladding and increasing the radial hydride precipitation in the zirconium alloy cladding. and other problems, to achieve the effect of easy implementation, recovery of toughness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0046] Principle of the method:

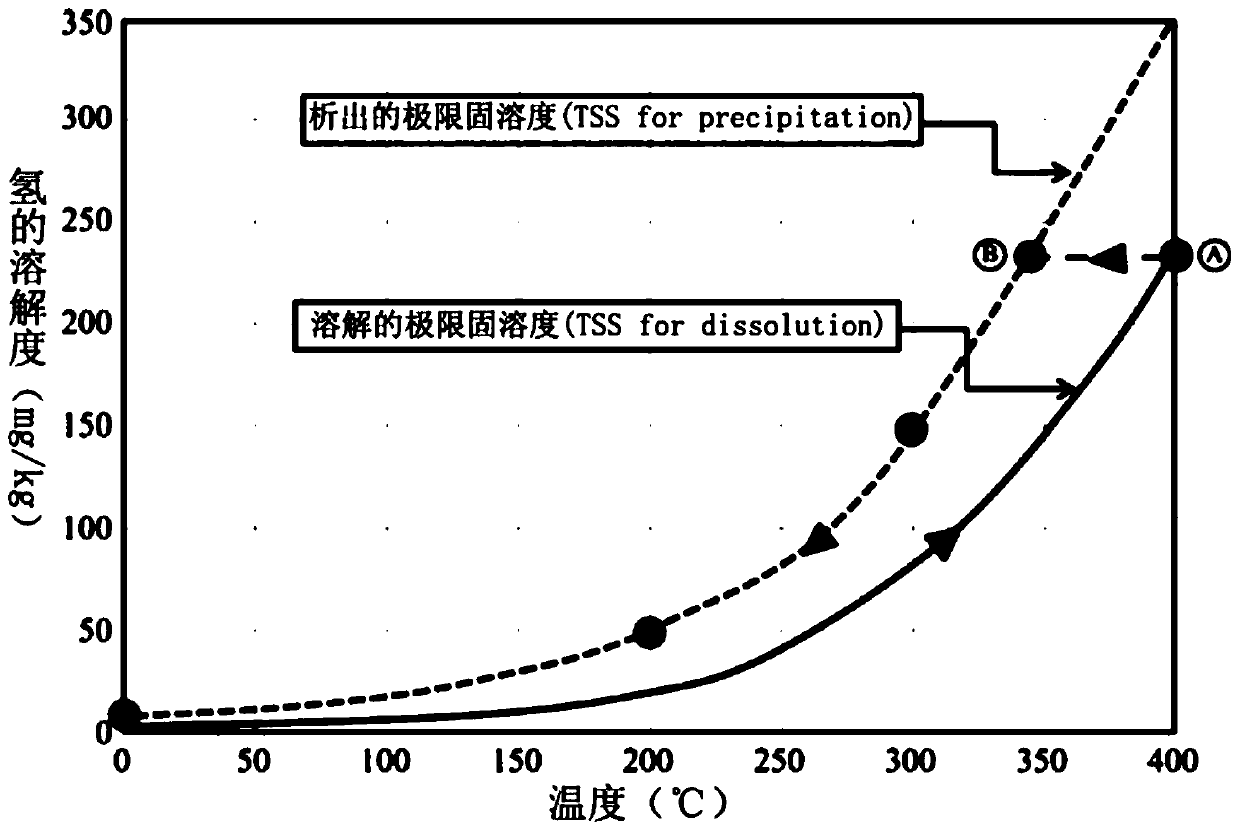

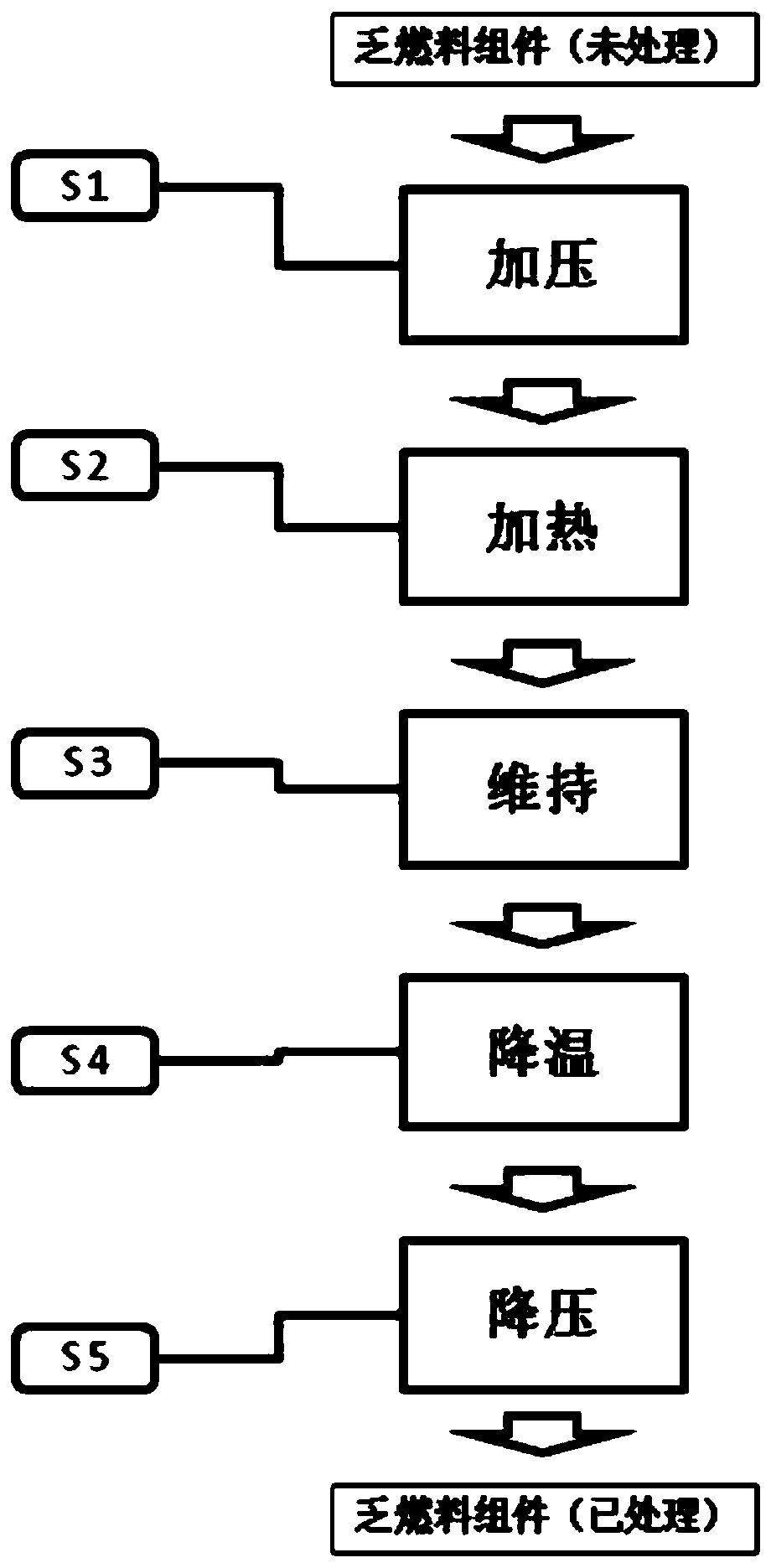

[0047] The solubility of hydrogen in the zirconium alloy cladding of the spent fuel assembly decreases as the temperature decreases ( figure 1), precipitated from the solid solution state to the solid state of the compound. Hydrogen compounds exist in two forms: radial hydrides and ring hydrides. One of the conditions for the generation of hydrides in two different directions is the direction and magnitude of the internal stress of the zirconium alloy cladding material at the moment of precipitation. If the hoop tensile stress of the zirconium alloy cladding (usually generated by internal pressure) is higher than a certain critical value, hydrogen will be precipitated in the form of radial hydrides during cooling, and this orientation of hydrides will seriously reduce the cladding. toughness. Another hoop hydride do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com