A method for improving the toughness of spent fuel zirconium alloy cladding material

A cladding material, zirconium alloy technology, applied in reactor fuel elements, climate sustainability, reduction of greenhouse gases, etc., can solve the problem of increasing the risk of zirconium alloy cladding damage and aggravating radial hydride precipitation in the zirconium alloy cladding. Quantity and other issues, to achieve the effect of easy implementation, recovery of toughness, and increased ability to shock and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below with reference to the accompanying drawings and examples.

[0046] Method principle:

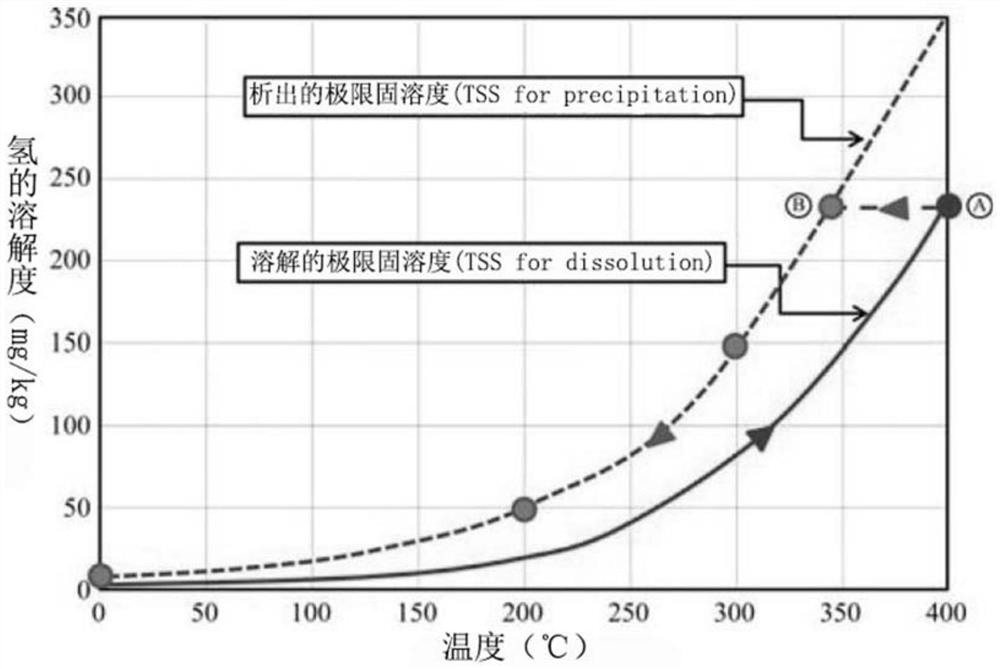

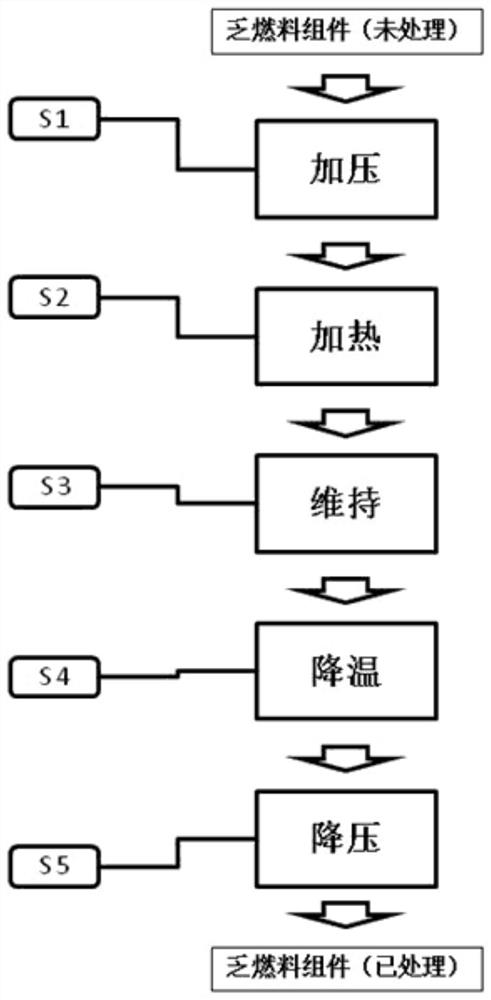

[0047] The solubility of the hydrogen in the zirconium alloy shell of the lack of fuel assembly decreases as the temperature decreases as the temperature is lowered. figure 1The solid was precipitated from the solid solution to the solid state. The compound of hydrogen has two forms: the radial hydride and the ring to the hydride. One of these two different directions of hydrides is one of the internal stress directions and stress sizes of the time zirconium alloy shell material. If the ring to pull stress of the zirconium alloy cladding (usually generated by internal pressure) is higher than a certain critical value, hydrogen is precipitated in the form of a radial hydride during the cooling process, which will severely reduce the shell in the form of a radial hydride during the cooling process. Toughness. Another cyclo-hydride does not re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com