Water level amplitude area panel maintenance intelligent system and control and maintenance method

An intelligent system and water level technology, applied in dams, manufacturing tools, ceramic molding machines, etc., can solve problems such as excessive climate temperature difference, inadequate maintenance, cracks, etc., to slow down the flow rate, reduce energy consumption, ensure reliability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

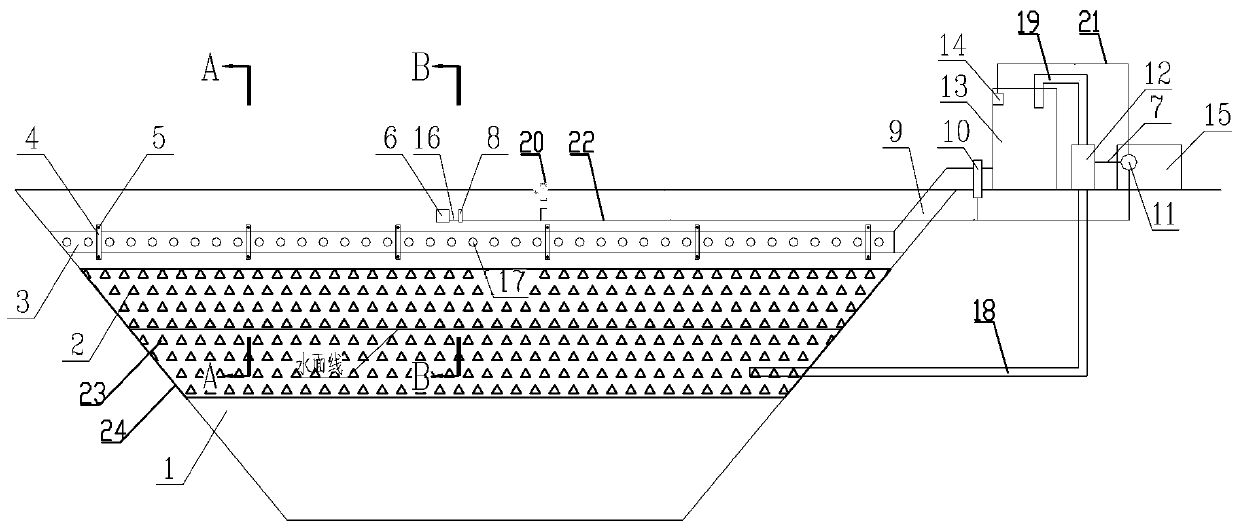

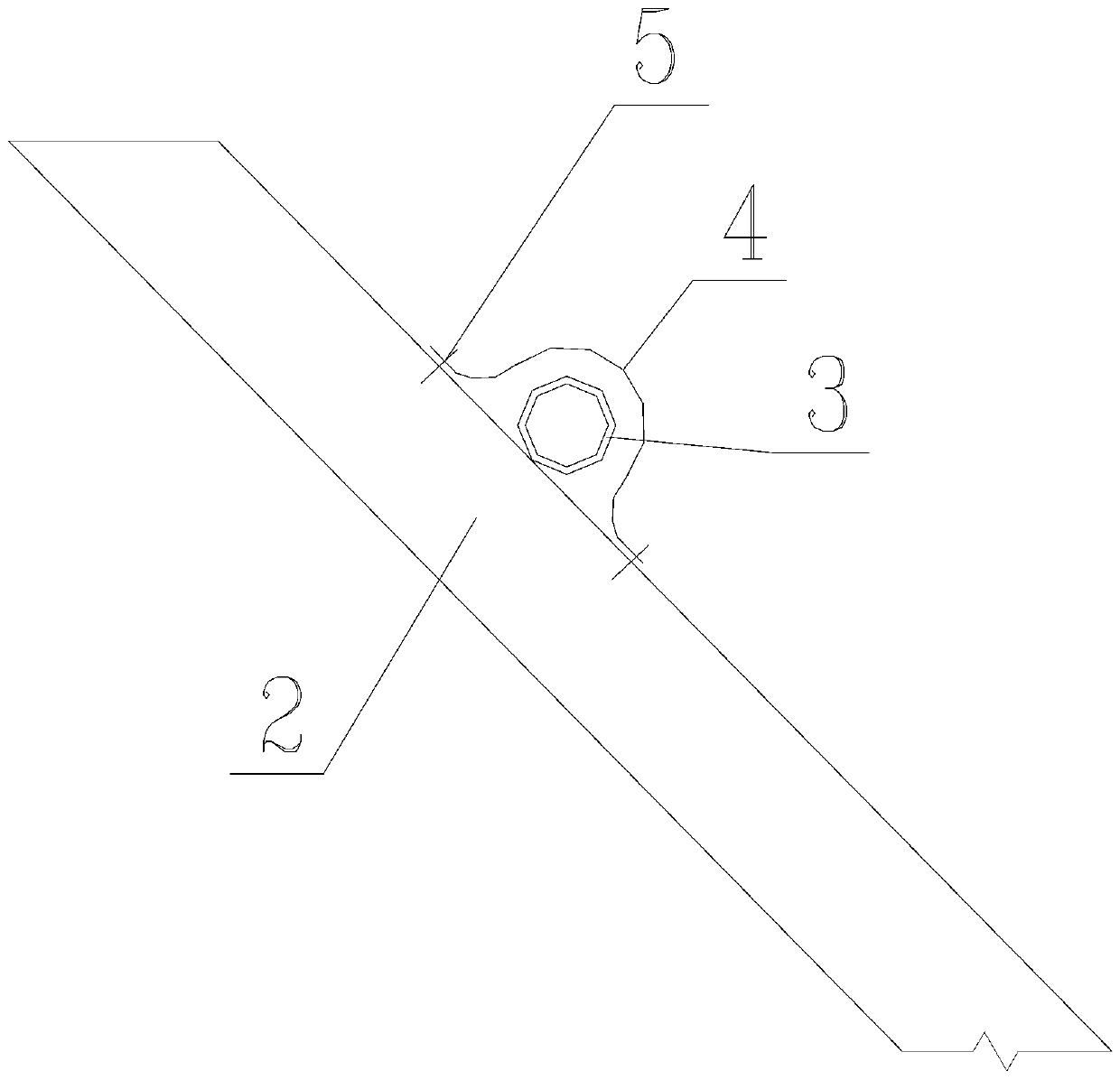

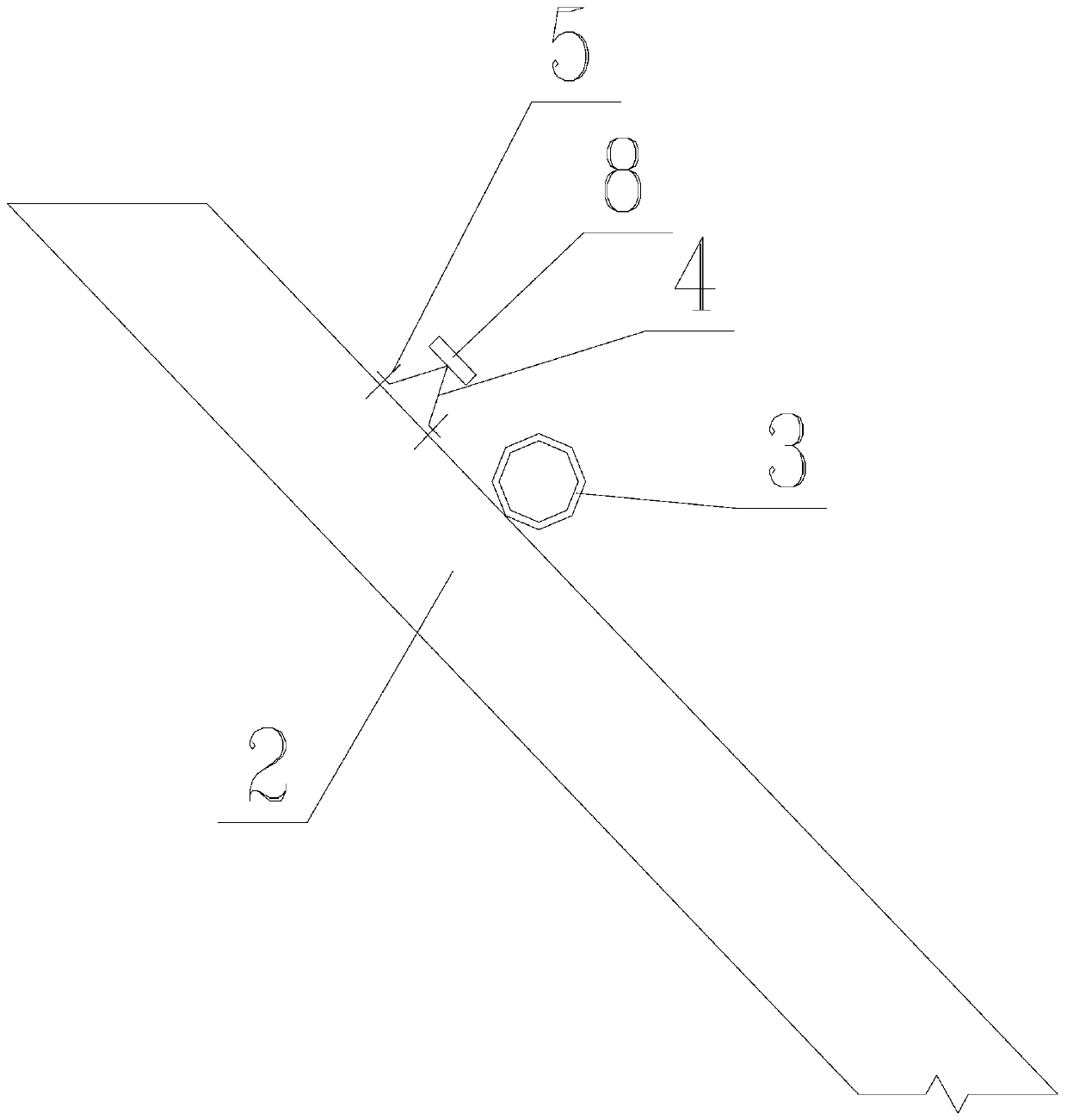

[0039] The panel maintenance intelligent system in the water level amplitude range area is mainly used on the concrete panel 2 in the water level range area with large climate temperature difference. The drainage flower pipe 3 is arranged on the top of the concrete panel 2, and its main function is to make the maintenance water flow out from the drainage hole 17 on the pipe wall; The panel area of the water level variable amplitude area is selected from 3 to 10 cm, and the thickness of the pipe wall is 0.1 to 0.5 cm; the drainage flower pipe 3 is provided with drainage holes 17, which are arranged in a line, with a diameter of 0.5 to 1 cm, and the hole spacing is usually 0.1 to 1 cm. 2m; the drainage flower pipe 3 is fixed on the concrete panel 2 with a bracket 4, the shape of the bracket 4 is semicircular, and the material of the bracket 4 is usually stainless steel sheet, the thickness of the stainless steel sheet is 0.1-0.3cm, the width of the stainless steel sheet is 1-2c...

Embodiment 3

[0045] The control method of the panel maintenance intelligent system in the water level amplitude range area is to collect the temperature and ambient temperature of the dam area from time to time through the temperature detector 8 and transmit the ambient temperature data to the controller 11 through the signal line, and at the same time through the evaporation detection device 20 Transmit the evaporation data of the reservoir water 1 in the dam area to the controller 11 through the signal line; compare and analyze the temperature and evaporation data with the standard data respectively through the controller 11, when the ambient temperature is lower or higher than the allowable value or When the evaporation of the reservoir water 1 exceeds the allowable value, the controller 11 automatically controls the opening of the electric valve 10, and sprays water to the concrete panel 2 through the drainage flower pipe 3 for maintenance; the water level in the water tank 13 is monitor...

Embodiment 4

[0047] The method for maintaining the concrete panel by using any one of the intelligent system for panel maintenance in the water level amplitude range is characterized in that it includes the following steps:

[0048] Step 1, arranging the above-mentioned system at the location of the concrete panel 2 to be maintained;

[0049] Step 2, setting the control parameters of the control system: setting the ambient temperature range value of the concrete panel 2, and setting the limit value of the evaporation of the reservoir water 1;

[0050] Step 3, start the temperature acquisition instrument 8, collect the temperature and ambient temperature of the dam area from time to time through the temperature acquisition instrument 8 and transmit the ambient temperature data to the controller 11 through the signal line, and simultaneously pass the evaporation detection device 20 to the dam area. The evaporation data of the reservoir water 1 is transmitted to the controller 11 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com