Reinforced concrete prefabricated part

A technology of reinforced concrete and prefabricated parts, applied in excavation, protective devices, construction, etc., can solve problems such as swelling cracked concrete, weak joints, water seepage, steel bar corrosion, etc., to reduce the strength of the board body and increase the effect of small cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

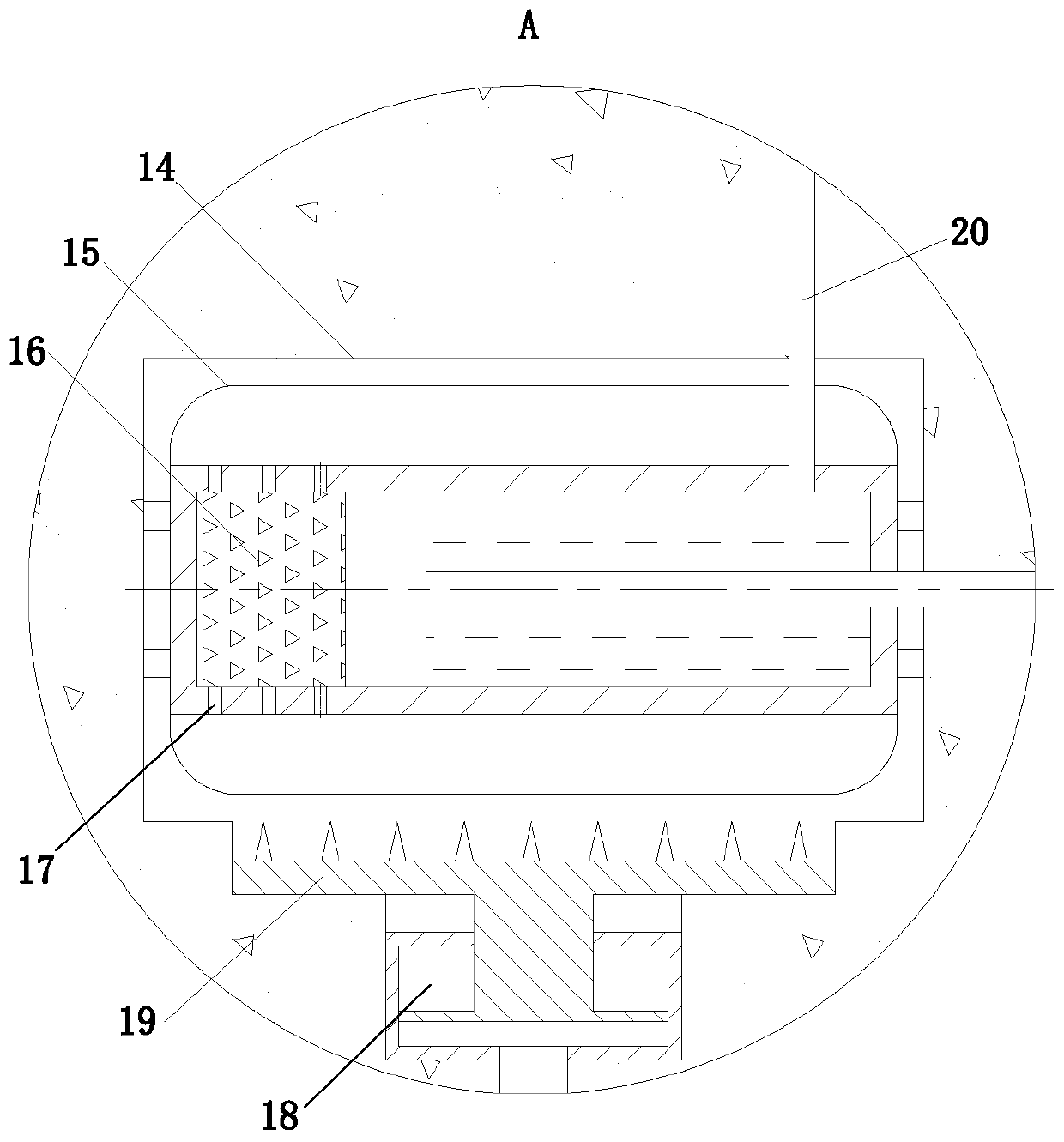

[0022] As an embodiment of the present invention, it is characterized in that: the anti-seepage unit 3 includes a cavity 14, a sealed cavity 15, a No. 3 piston 16, a small hole 17, a cylinder 18, a nail plate 19 and a glue injection tube 20; The outside of the plate body 1 is the soil layer of the construction foundation pit; the plate body 1 on the side of the No. 2 piston 6 close to the soil layer is provided with a cavity 14, and the cavity 14 is provided with a sealed cavity 15, and the sealed cavity 15 is A closed bag made of plastic film; No. 3 piston 16 is fixedly connected in the sealed cavity 15, and the piston cylinder on the side of No. 3 piston 16 close to the deck 10 is filled with water-absorbing resin, and the position of No. 3 piston 16 and the corresponding position of the absorbing resin A group of small holes 17 are evenly opened on the side wall of the piston cylinder; the piston cylinder on the side of the No. 3 piston 16 away from the deck 10 is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com