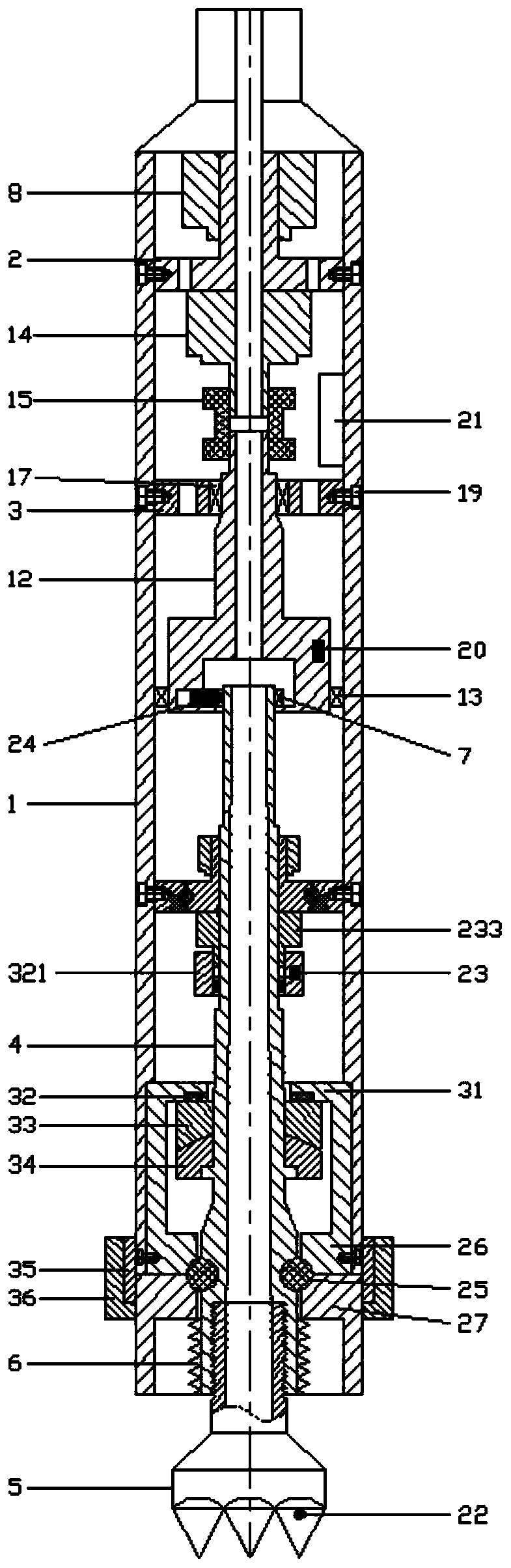

Efficient composite type drilling anti-sticking drilling twisting type tapered mill

An anti-blocking and duplex technology, which is applied in the field of oil and gas drilling, can solve the problems of poor stability of the drilling shaft, poor support, poor control of the drilling speed, and prone to fatigue damage, etc., to meet the needs of different geology demand, improve drilling efficiency, and prevent stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

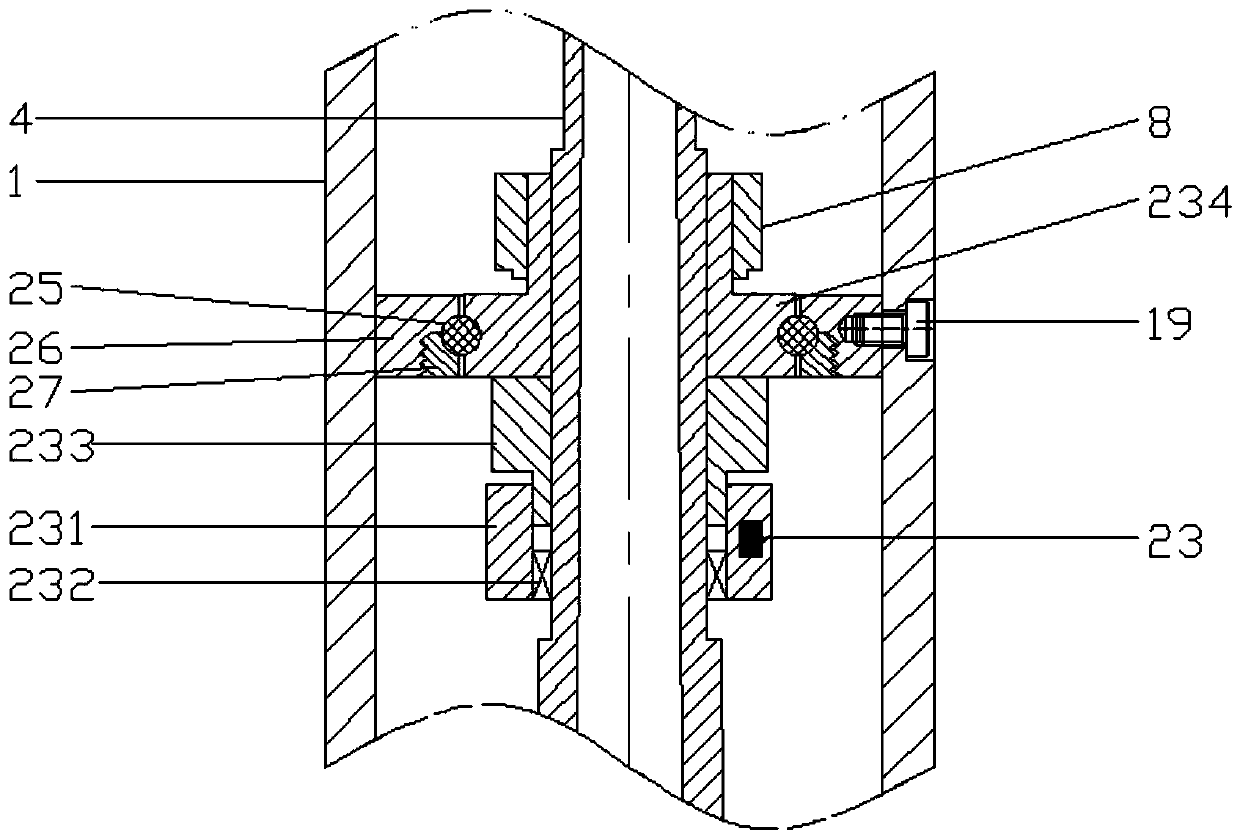

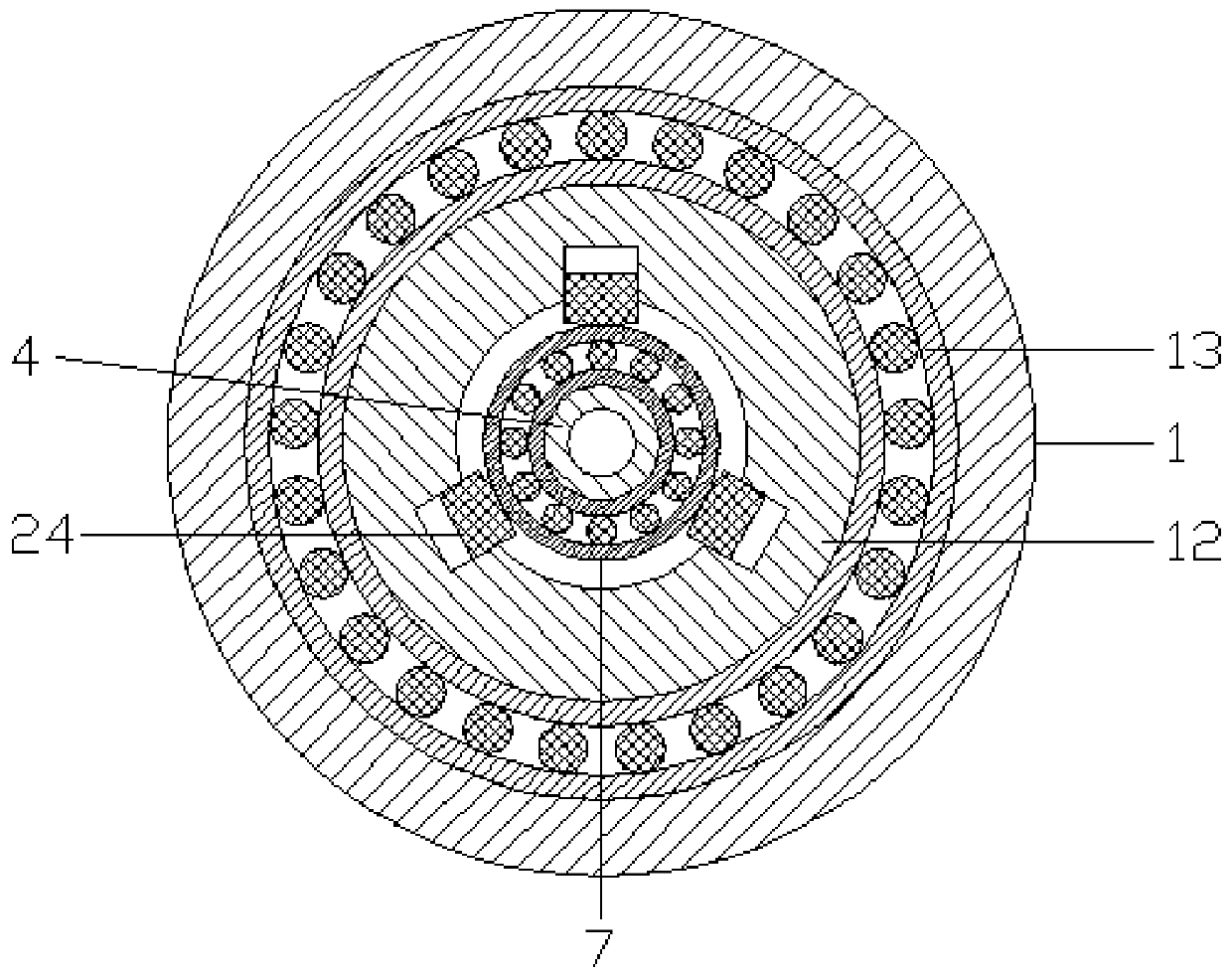

[0063] When drilling, the controller controls the rotation speed of the servo motor and the servo motor of the stabilized platform in real time through the gyroscope, so that the main body of the stabilized platform and the drill shaft seat are relatively stationary when working. When the drill shaft tilts during drilling, the drill shaft The gyroscope sends the tilt signal of the drilling shaft to the controller, and the controller compares the received angle signal with the internally set program and / or the program sent by the ground. When the received angle signal is compared with the internally set When the angle signal and / or the angle signal sent by the ground are inconsistent, the connected hydraulic drive piston is driven, and the linear slider on the hydraulic drive piston drives the drill shaft to move for angle correction, so that the angle of the drill shaft is consistent with the internally set angle signal And / or the angle signal sent by the ground is consistent; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com