Hot air valve for wax removal, hot air wax removal system and artificial intelligence wax removal method

A technology of hot air and valves, applied in sliding valves, valve devices, earthwork drilling and mining, etc., can solve the problems of high cost of wax removal, high power consumption, and only reverse cycle hot washing, etc., and achieve the effect of low cost of wax removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

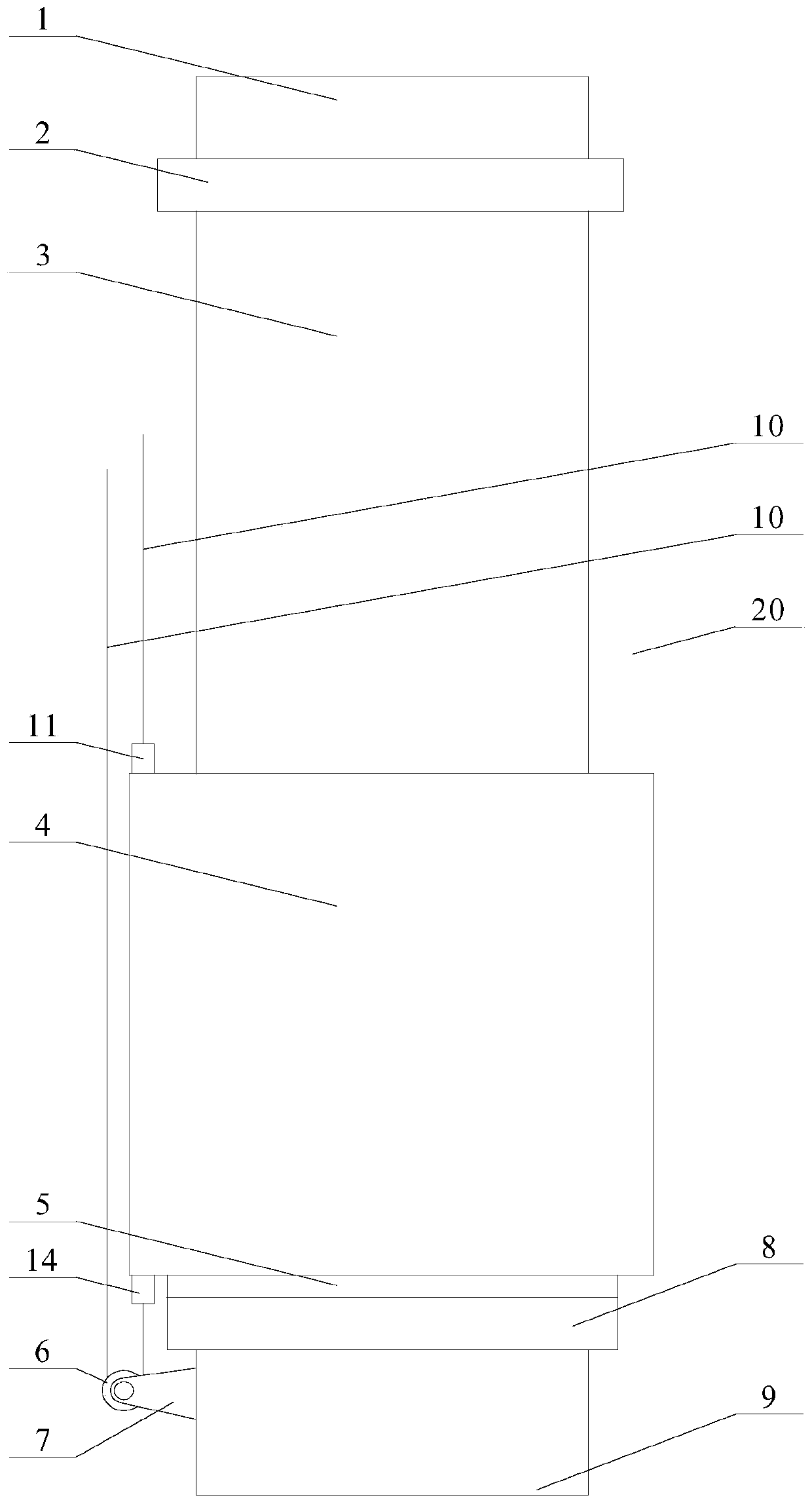

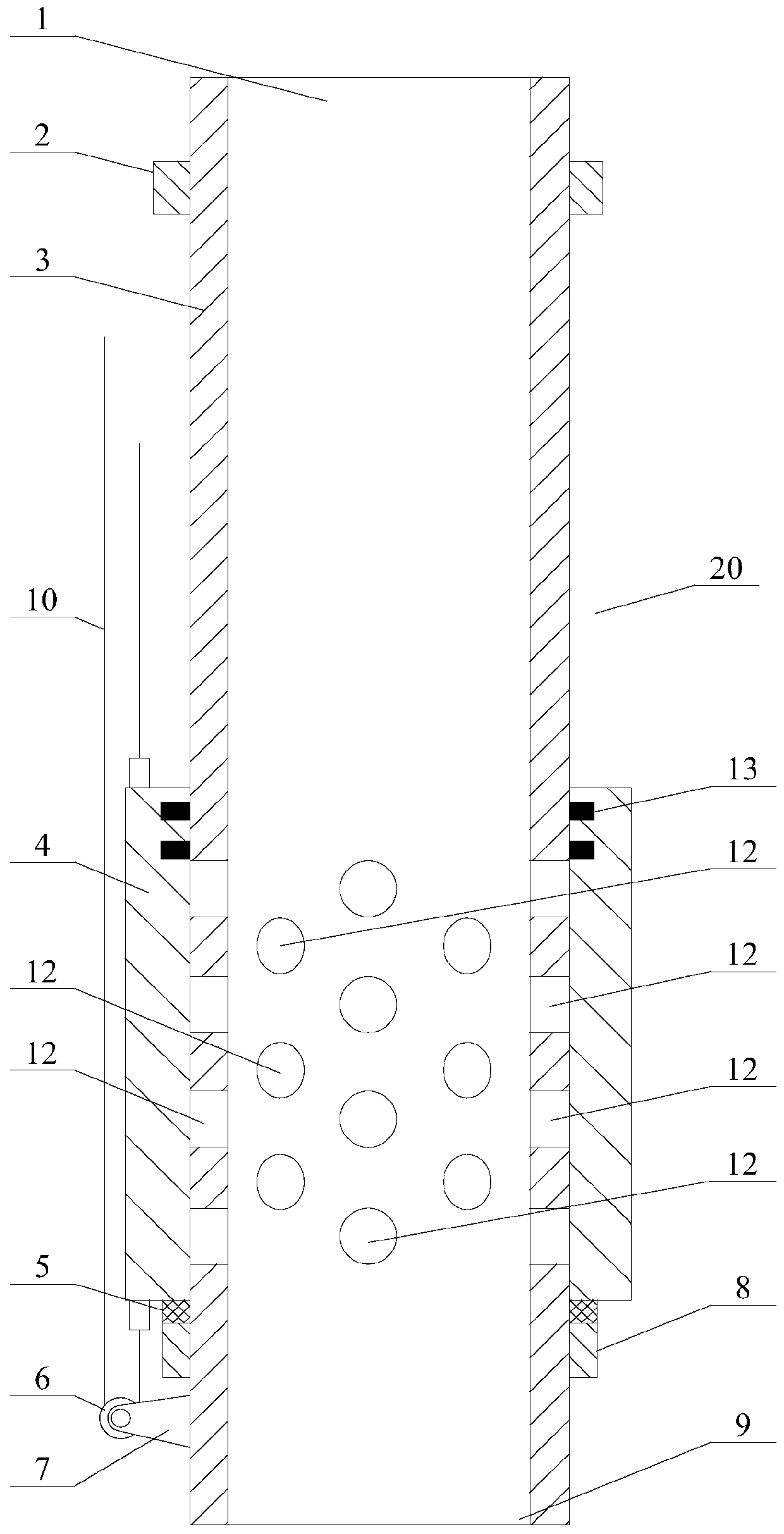

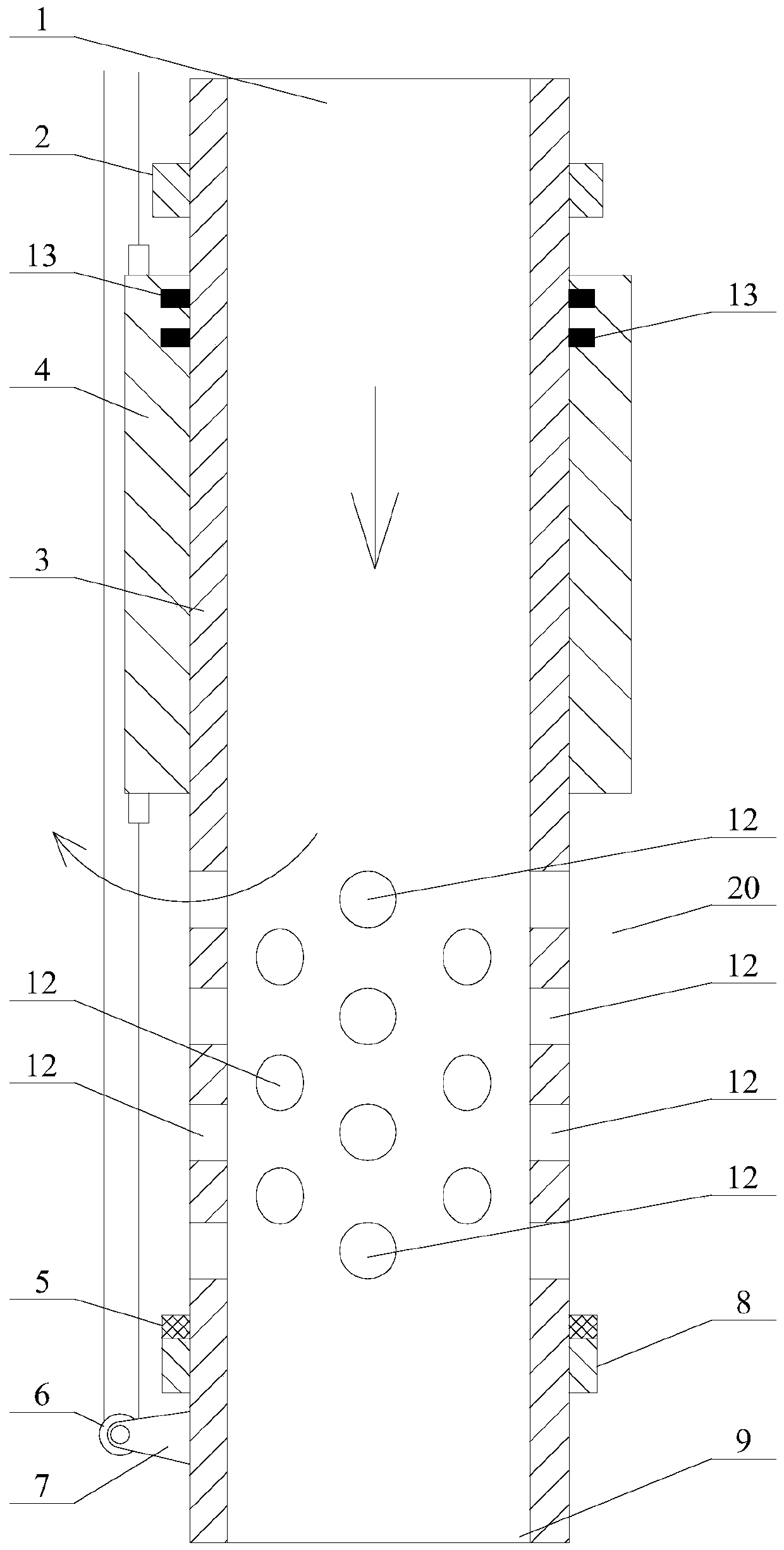

[0027] like Figure 1 ~ Figure 3 As shown, a hot air valve for wax removal involved in this embodiment, the hot air valve 20 includes an upper ferrule 2, an inner pipe 3, an outer pipe 4, a sealing gasket 5, a pulley 6, a pulley frame 7, and a lower ferrule 8. Steel wire rope 10, upper steel wire rope fastener 11, piston ring 13 and lower steel wire rope fastener 14, the outer pipe 4 is set on the inner pipe 3, the outer pipe 4 and the inner pipe 3 are slidingly connected, and the inner pipe 3 The lower part is provided with some hot air passage holes 12 within a range less than the height of the outer pipe 4, the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com