One-story construction waste transportation and treatment device

A construction waste and processing device technology, applied in grain processing, separation methods, use of liquid separation agents, etc., can solve the problems of high labor intensity, safety hazards, pollution, etc., and achieve the effect of reducing labor intensity and avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

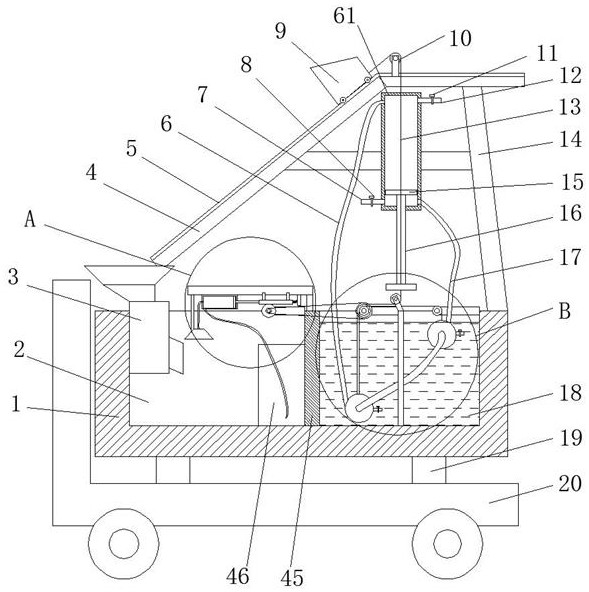

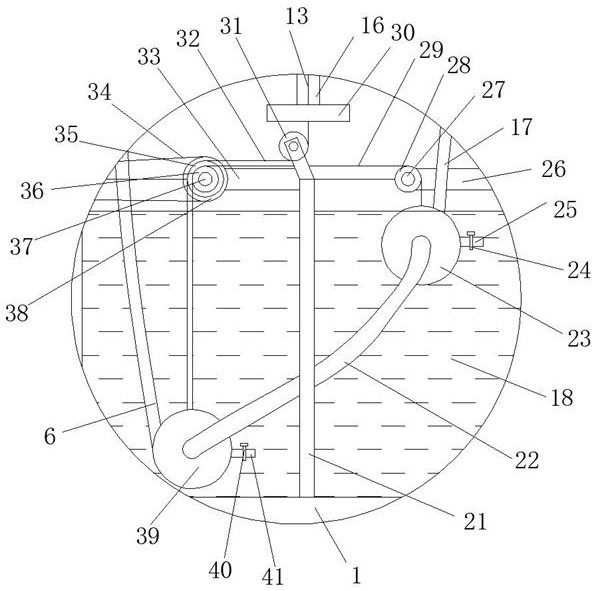

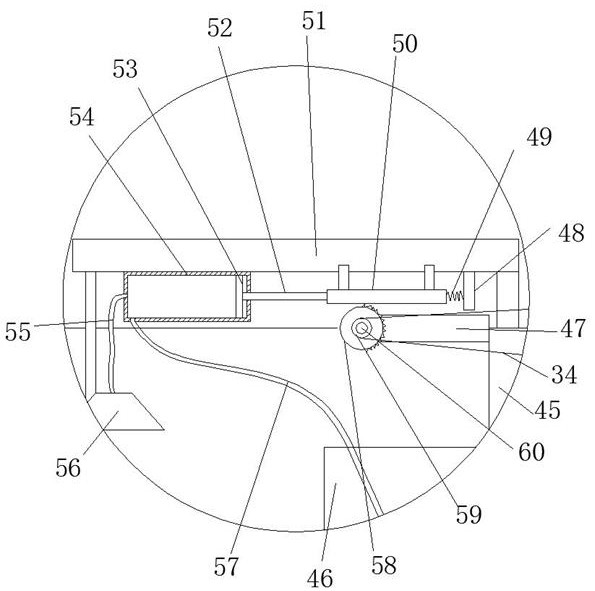

[0024] see Figure 1-4 , a one-story construction waste transportation and processing device, including a mobile frame 20, a lifting frame 1 is connected to the moving frame 20 through an electric telescopic rod 19, and a tilting plate 4 and a cylinder block 61 are fixedly connected to the lifting frame 1 through a fixing frame 14 , the waste frame 9 is slidably connected on the inclined plate 4, the piston 15 is slidably connected in the cylinder body 61, the piston rod 16 is fixedly connected to the lower side of the piston 15, the pressing plate 30 is fixedly connected to the lower end of the piston rod 16, and the rotatable connection is made on the inclined plate 4. There is a guide wheel 10, and a pull rope 13 is connected to the pressing plate 30. The end of the pull rope 13 away from the pressing plate 30 goes around the guide wheel 10 and is fixedly connected with the waste frame 9. The lifting frame 1 is divided into a crushing chamber 2 by a partition plate 45 And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com