A municipal subway construction steel plate rapid cutting equipment

A rapid cutting and subway technology, applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problems of unguaranteed cutting accuracy, low cutting efficiency, and time-consuming, so as to improve work efficiency, quality, and cutting speed Fast, labor-saving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

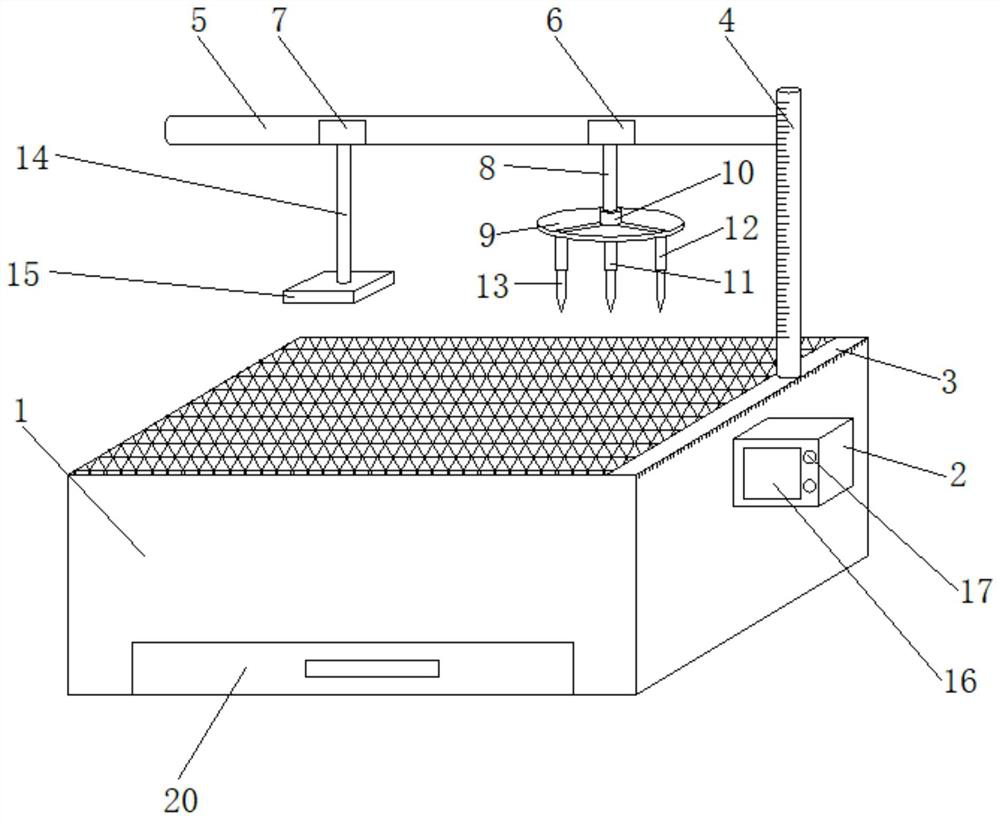

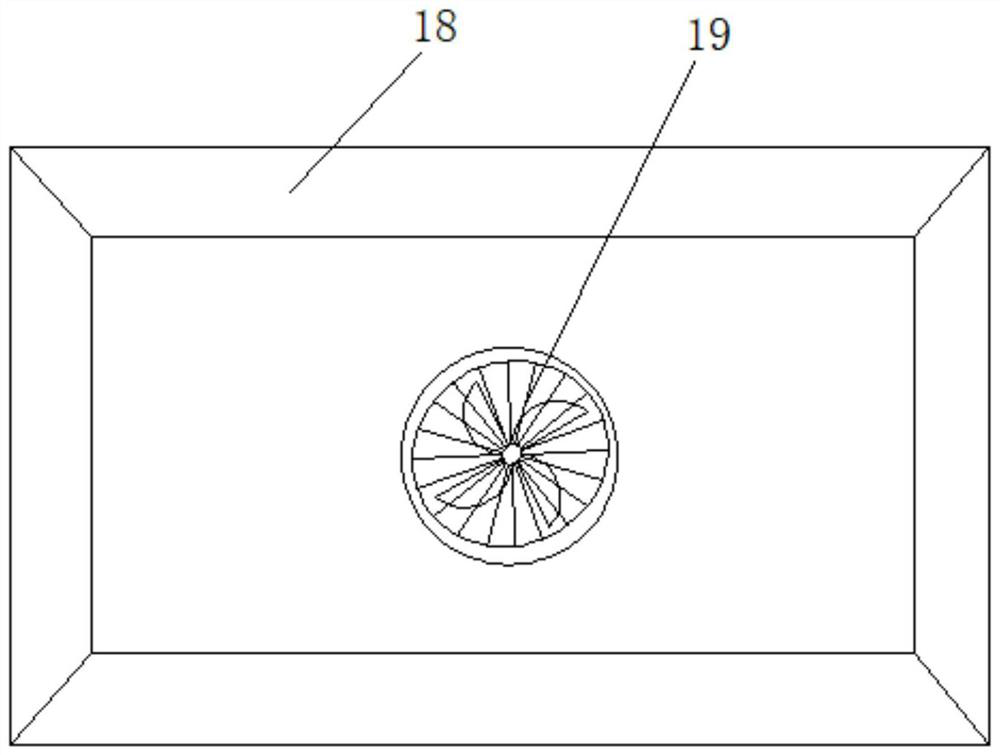

[0027] The invention provides a kind of quick cutting equipment for municipal subway construction steel plates, specifically as Figure 1 to Figure 4 As shown, it includes a cutting table 1, a lifting device, a cutting device, a fixing device and a control box 2;

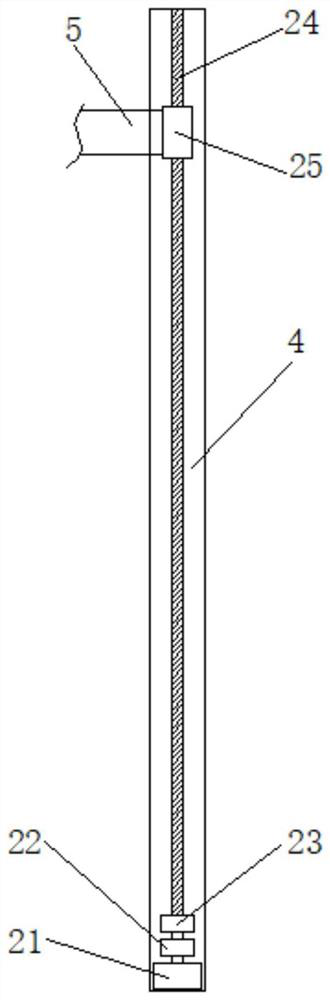

[0028] The top side of the cutting table 1 is provided with a track 3, and an electric pulley cooperating with the track 3 is arranged inside the track 3. The lifting device includes a column 4 and a beam 5 with a cavity. The track 3 moves to realize the feeding task of cutting. One end of the crossbeam 5 is slidingly connected with the column 4, and the height of the crossbeam 5 can be adjusted through the sliding connection, and then the distance between the cutting knife and the cutting table 1 can be adjusted to realize the rising and falling of the cutting knife. A first sliding device 6 and a second sliding device 7 are arranged in the crossbeam 5. The cutting device includes a first connecting rod 8, a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com