Preparation method for boron nitride fiber reinforced silicon boron oxygen nitrogen ceramic based composite material

A technology of silicon boron oxynitride ceramics and boron nitride fiber, which is applied in the field of preparation of boron nitride fiber reinforced silicon boron oxynitride ceramic matrix composite materials, can solve the problems of immature production of continuous boron nitride fiber and achieve dispersion Good, the process is simple and efficient, and the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

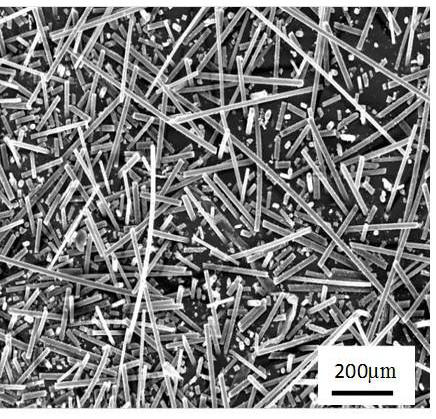

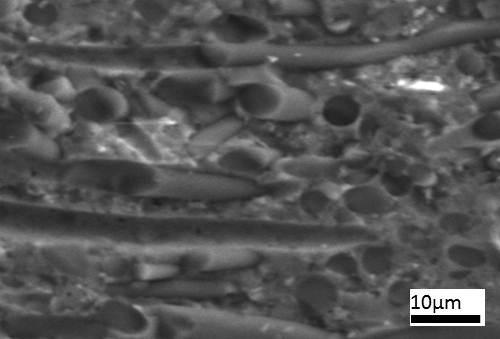

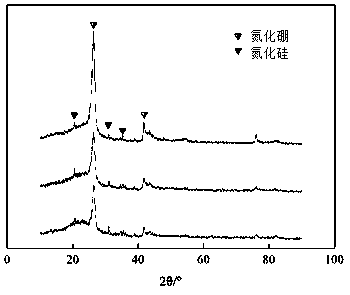

[0019] Put the flocculent boron nitride fiber in a ball mill jar, add acetone according to the mass ratio of 1:2, and add zirconia balls according to the material-to-ball ratio of 1:45, and then ball mill on a planetary ball mill at a speed of 200 rpm for 8 minutes Boron nitride short fibers are obtained. The boron nitride short fiber and silicon boron oxynitride ceramic powder are uniformly mixed in a ball mill mixer according to the proportion of boron nitride short fiber added to 20% of the mass of all powders to obtain raw materials for preparing ceramic matrix composite materials. The raw materials are dried and sieved and loaded into a mold for hot-press sintering. The hot-press sintering process parameters are: heating rate 5°C / min, sintering temperature 1700°C, holding time 1 hour, pressure 20MPa. After the hot pressing sintering process is completed, it is cooled with the furnace, and the boron nitride fiber reinforced silicon boron oxygen nitrogen composite material ...

Embodiment 2

[0021] Put the flocculent boron nitride fiber in a ball mill jar, add acetone according to the mass ratio of 1:2, and add zirconia balls according to the material-to-ball ratio of 1:45, and then ball mill on a planetary ball mill at a speed of 200 rpm for 8 minutes Boron nitride short fibers are obtained. The boron nitride short fiber and silicon boron oxynitride ceramic powder are uniformly mixed in a ball mill mixer according to the proportion of boron nitride short fiber added to 20% of the mass of all powders to obtain raw materials for preparing ceramic matrix composite materials. The raw materials are dried and sieved, and then loaded into a mold for hot-press sintering. The hot-press sintering process parameters are: heating rate 5°C / min, sintering temperature 1600°C, holding time 1 hour, pressure 20MPa. After the hot pressing sintering process is completed, it is cooled with the furnace, and the boron nitride fiber reinforced silicon boron oxygen nitrogen composite mat...

Embodiment 3

[0023] Put the flocculent boron nitride fiber in a ball mill jar, add acetone according to the mass ratio of 1:2, and add zirconia balls according to the material-to-ball ratio of 1:45, and then ball mill on a planetary ball mill at a speed of 200 rpm for 8 minutes Boron nitride short fibers are obtained. The boron nitride short fiber and silicon boron oxynitride ceramic powder are uniformly mixed in a ball mill mixer according to the proportion of boron nitride short fiber added to 20% of the mass of all powders to obtain raw materials for preparing ceramic matrix composite materials. The raw materials are dried and sieved and loaded into a mold for hot-press sintering. The hot-press sintering process parameters are: heating rate 5°C / min, sintering temperature 1500°C, holding time 1 hour, pressure 20MPa. After the hot pressing sintering process is completed, it is cooled with the furnace, and the boron nitride fiber reinforced silicon boron oxygen nitrogen composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com