Return stroke mechanism and tilting tray type plunger pump or motor including structure

A technology of return stroke and swash plate, which is applied to variable capacity pump components, components of pumping devices for elastic fluids, pumps, etc. It can solve design and installation difficulties, pump heat cannot be dissipated, and central spring rigidity is large, etc. problems, to achieve the effects of unbalanced oil film distribution, noise reduction, convenient design and installation, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

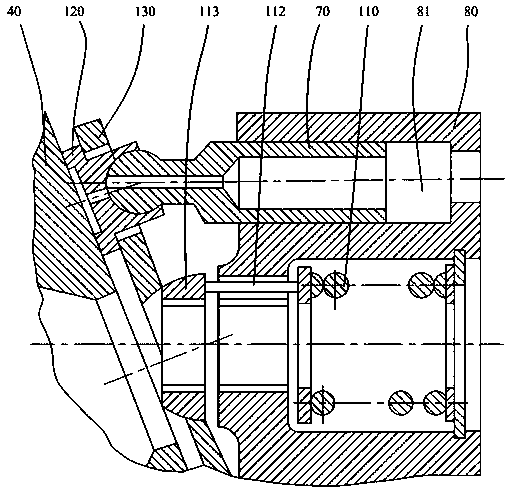

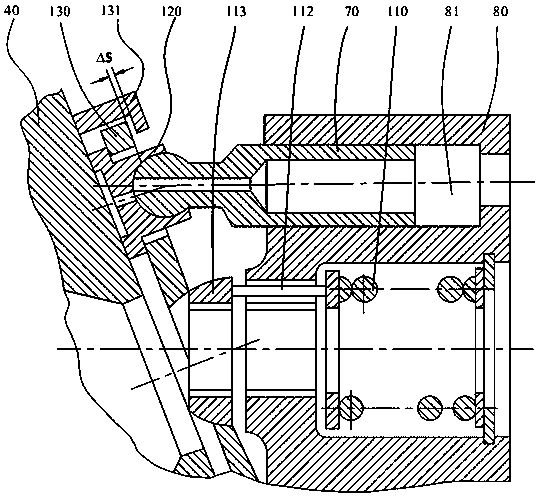

[0038] Such as Figure 4-Figure 7 Shown is an embodiment of the swash plate type plunger pump including the return mechanism of the present invention. In the preferred embodiment shown, the swash plate type piston pump or motor includes a main shaft 10, a housing, a first Bearing 21, swash plate 40, slide plate 50, plunger 70, cylinder block 80, flow plate 90. The main shaft axis 10C of the main shaft 10 coincides with the cylinder central axis 80C of the cylinder block 80 , one end of the main shaft 10 is supported on the first bearing 21 , and the other end passes through the valve plate 90 and is connected to the cylinder block 80 through a key. connected, the static pressure bearing surface 50a of the sliding plate 50 is supported on the swash plate 40, and keeps in close fit with the working surface of the swash plate 40, the middle part of the sliding plate 50 has a central through hole 510 of the sliding plate, and the swash plate The middle part of 40 has a support sh...

Embodiment 2

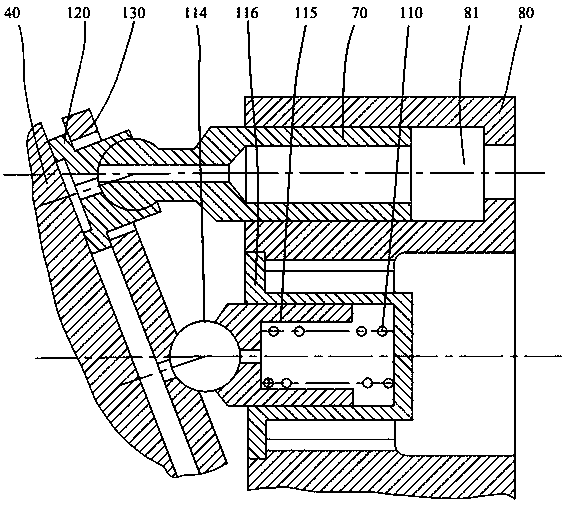

[0061] Such as Figure 8 and Figure 9 As shown, the difference from Embodiment 1 lies in the structure of the sliding plate, the supporting position of the sliding plate and the arrangement of the restraining components.

[0062] Such as Figure 8 Shown is another embodiment of the swash plate type plunger pump including the return mechanism of the present invention. In the preferred embodiment shown, the swash plate type piston pump or motor includes a main shaft 10, a casing, a second A bearing 21, a swash plate 40, a slide plate 50, a plunger 70, a cylinder block 80, and a flow plate 90. The main shaft axis 10C of the main shaft 10 coincides with the cylinder central axis 80C of the cylinder block 80 , one end of the main shaft 10 is supported on the first bearing 21 , and the other end passes through the valve plate 90 and is connected to the cylinder block 80 through a key. Connected, the static pressure bearing surface 50a of the sliding plate 50 is supported on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com