3D NAND flash memory and method of fabricating the same

A technology of flash memory and suppression layer, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of dielectric layer breakdown between adjacent gate layers, gate layer threshold voltage drift, and storage layer coupling interference, etc. Achieve the effects of reducing threshold voltage drift, reducing leakage, and improving breakdown resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

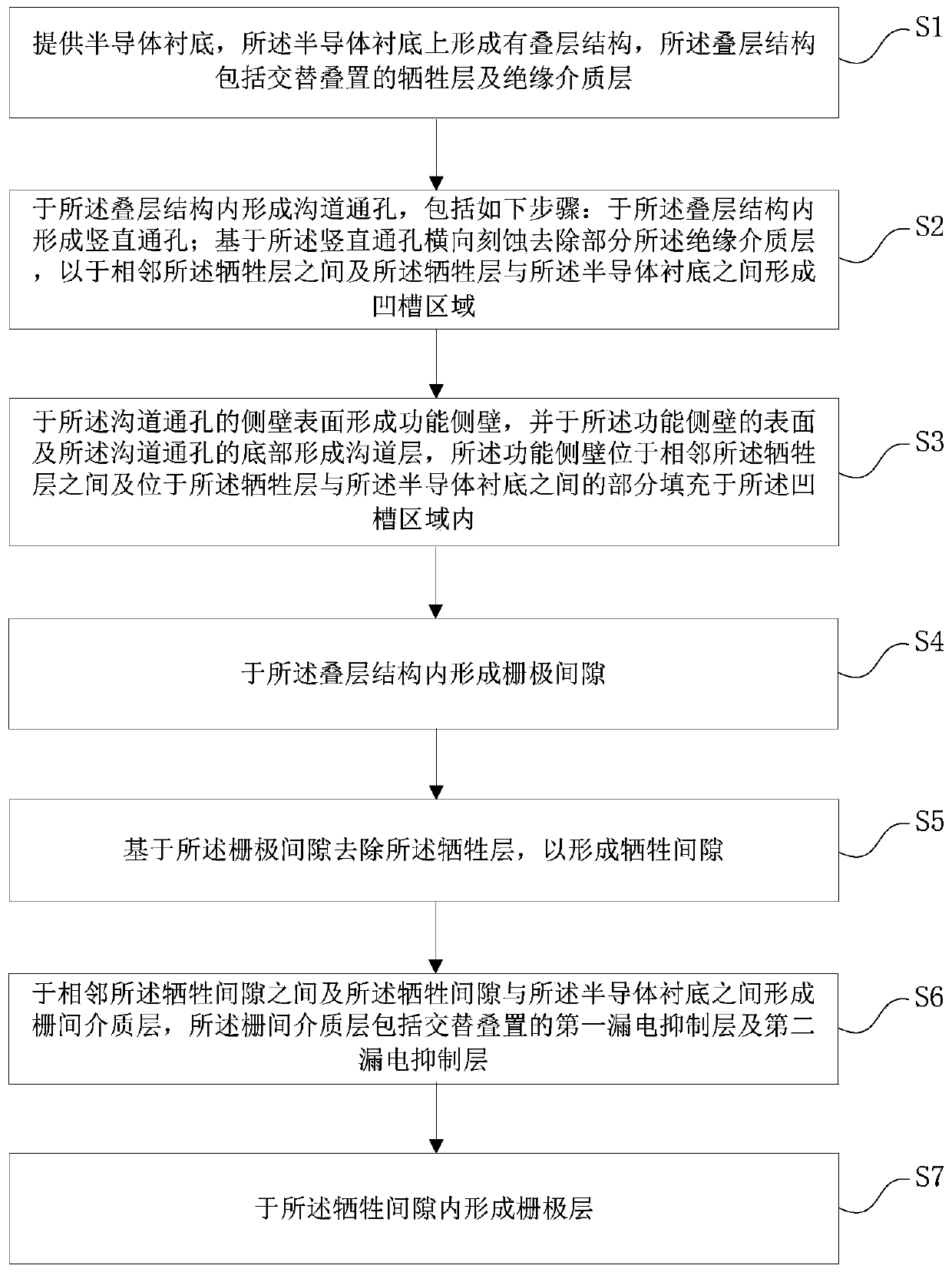

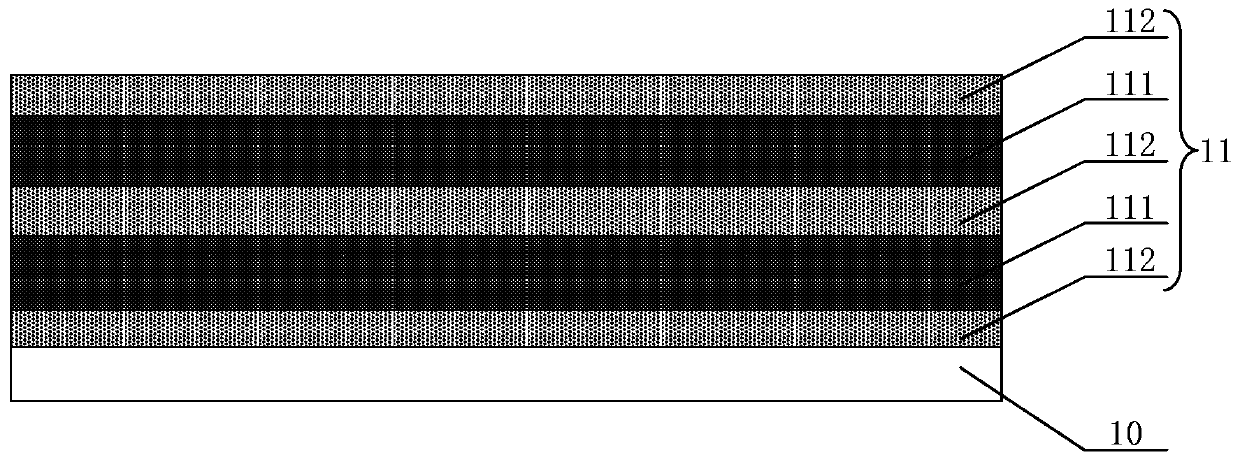

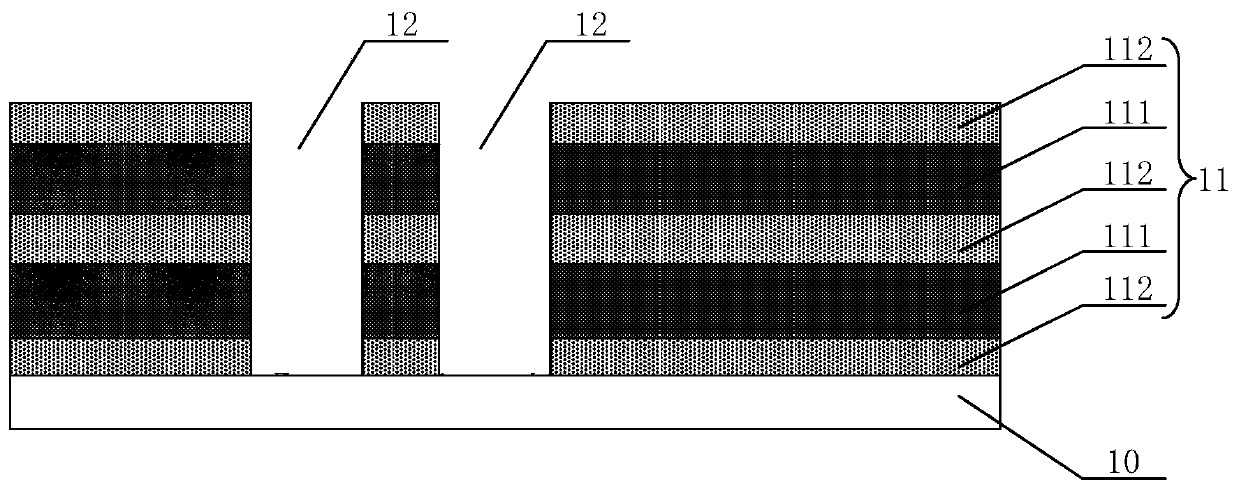

[0108] see figure 1 , the present invention provides a kind of preparation method of 3D NAND flash memory, the preparation method of described 3D NAND flash memory comprises steps:

[0109] 1) providing a semiconductor substrate, on which a stacked structure is formed, and the stacked structure includes alternately stacked sacrificial layers and insulating dielectric layers;

[0110]2) forming a channel via hole in the laminated structure, comprising the steps of: forming a vertical via hole in the laminated structure; removing part of the insulating dielectric layer by lateral etching based on the vertical via hole, forming a groove region between adjacent sacrificial layers and between the sacrificial layer and the semiconductor substrate;

[0111] 3) forming a functional sidewall on the surface of the sidewall of the channel through hole, and forming a channel layer on the surface of the functional sidewall and the bottom of the channel through hole; The portion between t...

Embodiment 2

[0189] see Figure 27 and Figure 28 , the present invention also provides a 3D NAND flash memory, the 3D NAND flash memory includes: a semiconductor substrate 10; a stacked structure 31, the stacked structure 31 is located on the semiconductor substrate 10, the stacked structure 10 includes Alternately stacked inter-gate dielectric layers 17 and gate layers 18, the inter-gate dielectric layer 17 includes alternately stacked first leakage suppression layers 171 and second leakage suppression layers 172; channel via holes 12, the channel The channel via hole 12 is located in the stacked structure 31; the channel via hole 12 includes a plurality of groove regions 122, and the groove region 122 is located between the adjacent gate layers 18 and the gate electrode Between the layer 18 and the semiconductor substrate 10; the functional sidewall 13, the functional sidewall 13 is located on the sidewall surface of the channel via hole 12, and the functional sidewall 13 is located ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com