Single bracket electric vehicle motor stator and manufacturing method

A technology of a motor stator and a manufacturing method, which is applied to the motor stator and manufacturing field of a single-support electric vehicle, can solve problems such as poor motor performance, and achieve the effects of good motor performance, reduction of welding steps, and high motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

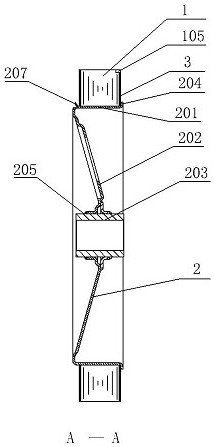

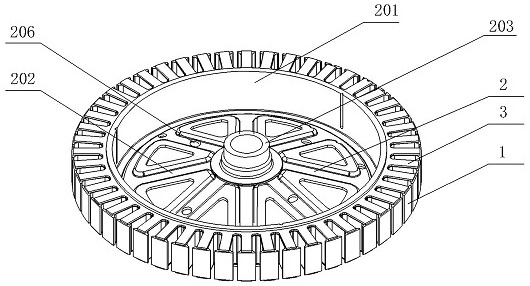

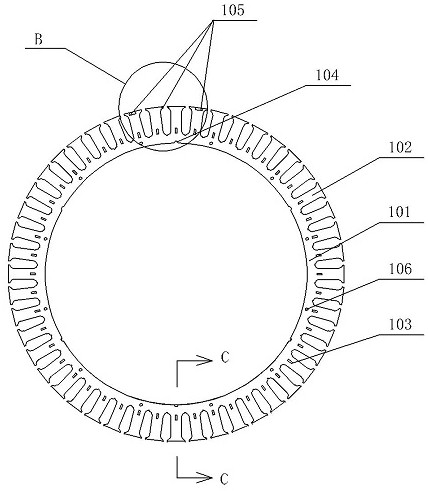

[0044] Such as figure 1 , figure 2 , image 3The shown provides a single-bracket electric vehicle motor stator, including a stator core 1 and a bracket main body 2 matching with the inner circular surface of the stator core 1. The bracket main body 2 includes a cylindrical iron core mounting part 201, a disc Shaped support part 202 and shaft sleeve 203, one end of the cylindrical iron core installation part 201 is connected with the support part 202, and the other end of the iron core installation part 201 is provided with a flange 204 formed outwardly in the circumferential direction. The purpose of 204 is to fix the stator core 1 on the one hand, and to make the processing more convenient, because the flange 204 has been set on the core installation part 201, so when the stator core 1 is press-fitted, the flange Edge 204 plays the role of positioning and fixing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com