Method for producing electrode for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and a manufacturing method, which is applied to the manufacturing of electrolytic capacitors, electrolytic capacitors, capacitor electrodes, etc., can solve the problems of gas discharge, porous layer damage, clogging, etc., and achieve the effect of reducing clogging and reducing leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

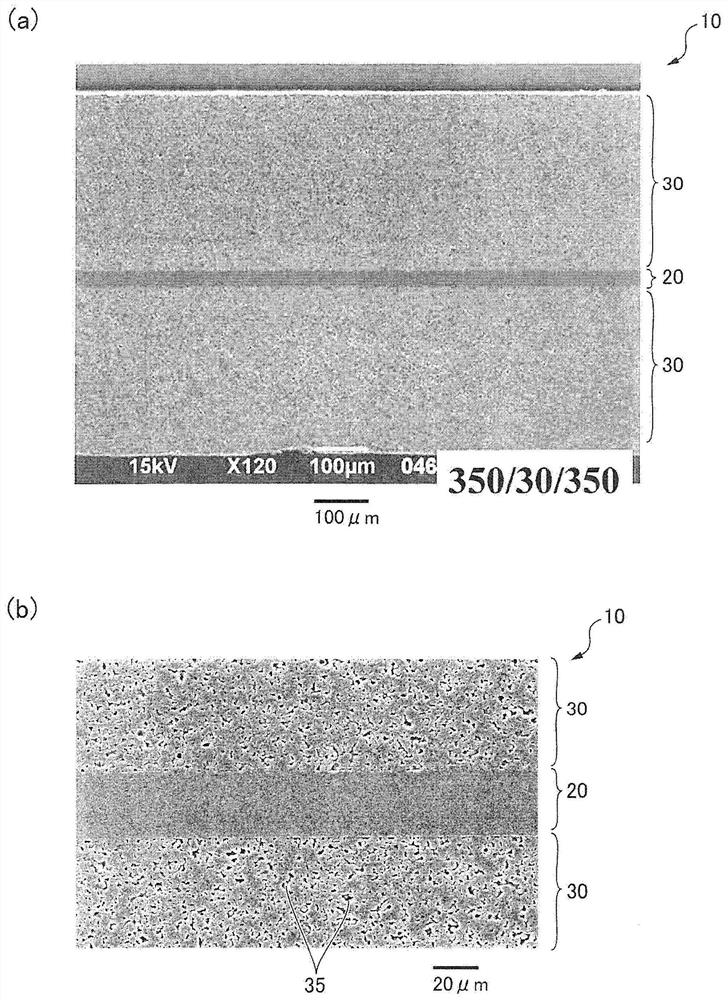

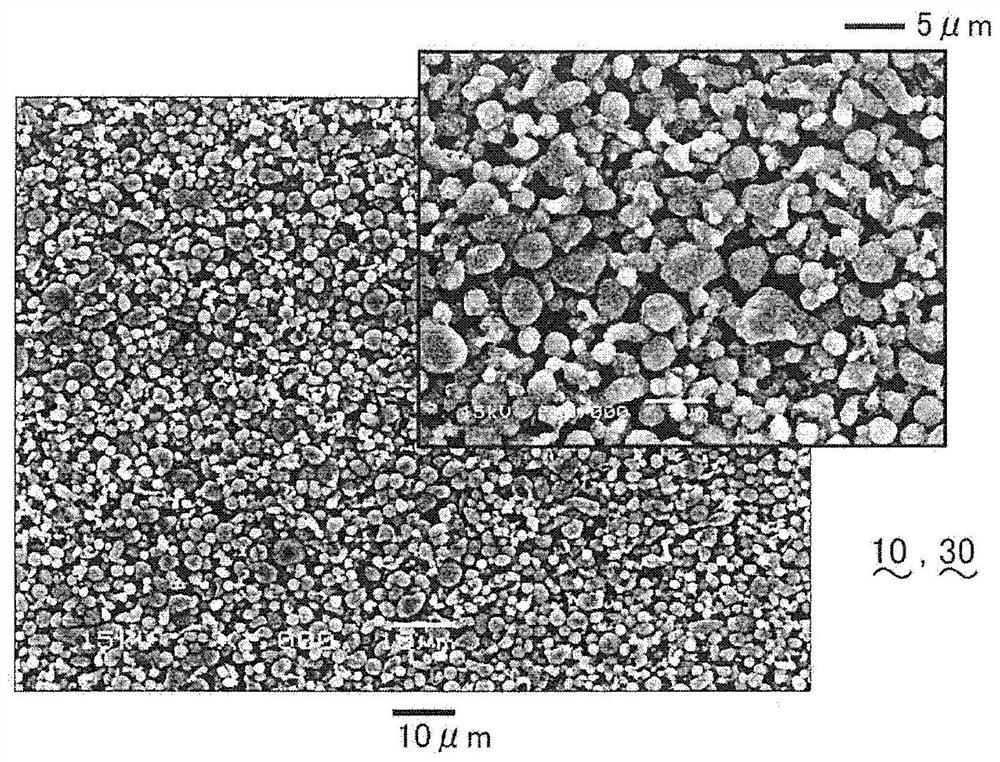

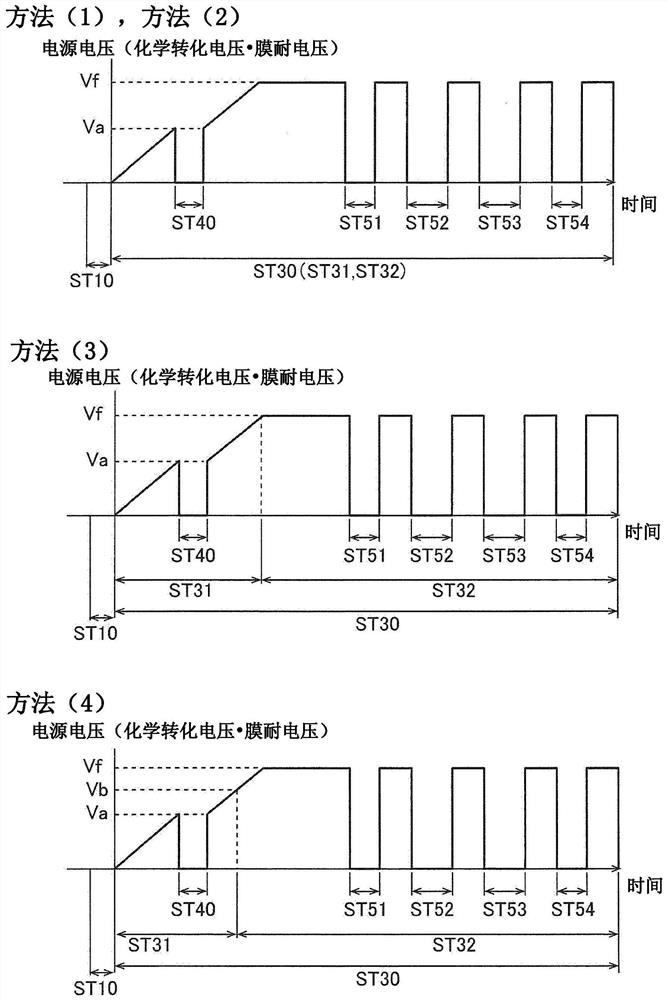

[0034]In the present invention, when producing an electrode for an aluminum electrolytic capacitor, the surface of the aluminum electrode is chemically converted to produce an electrode for an aluminum electrolytic capacitor. In the following description, as the aluminum electrode, a porous aluminum electrode in which a porous layer formed by sintering aluminum powder is laminated on both sides of an aluminum core material is used, and the case where the porous aluminum electrode is chemically converted is as follows: Center is explained. Next, after describing the configuration of the aluminum electrode, the chemical conversion method will be described.

[0035] (composition of aluminum electrodes)

[0036] figure 1 is an explanatory diagram showing a cross-sectional structure of an aluminum electrode according to the present invention, figure 1 (a) and (b) are photographs taken with an electron microscope magnifying the cross section of the aluminum electrode 120 times, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com