Fermented cake and manufacturing technique

A technology for making crafts and cakes, which is applied in pre-baking dough processing, baking, dough processing, etc. It can solve the problems of cakes not being fluffy enough, gas production is reduced, and gas is easy to escape into the air, so as to improve the flavor and nutritional value, increase gas production, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: A fermented cake, the raw materials included and their corresponding quality are shown in Table 1, and are prepared through the following steps:

[0065] Preliminary preparation: Grind the white granulated sugar into powder, and screen the white granulated sugar with a particle size of less than 20 mesh; screen the low-gluten flour with a particle size of less than 80 mesh;

[0066] Step 1: Beat whole eggs, white sugar, edible salt, glycerin, and sorbitol together according to parts by weight, then add low-gluten flour and foaming powder and mix evenly to obtain the first mixture;

[0067] Step 2: According to the parts by weight, add water with a water temperature of 12°C and dry yeast to the first mixture and mix evenly. The mixing speed is 300 rpm, and the mixing time is 12 minutes; then add vegetable oil and light cream, mix evenly, and beat. The speed used for sending is 560rpm, and the sending time is 1min to obtain the second mixture;

[0068] Step...

Embodiment 2-7

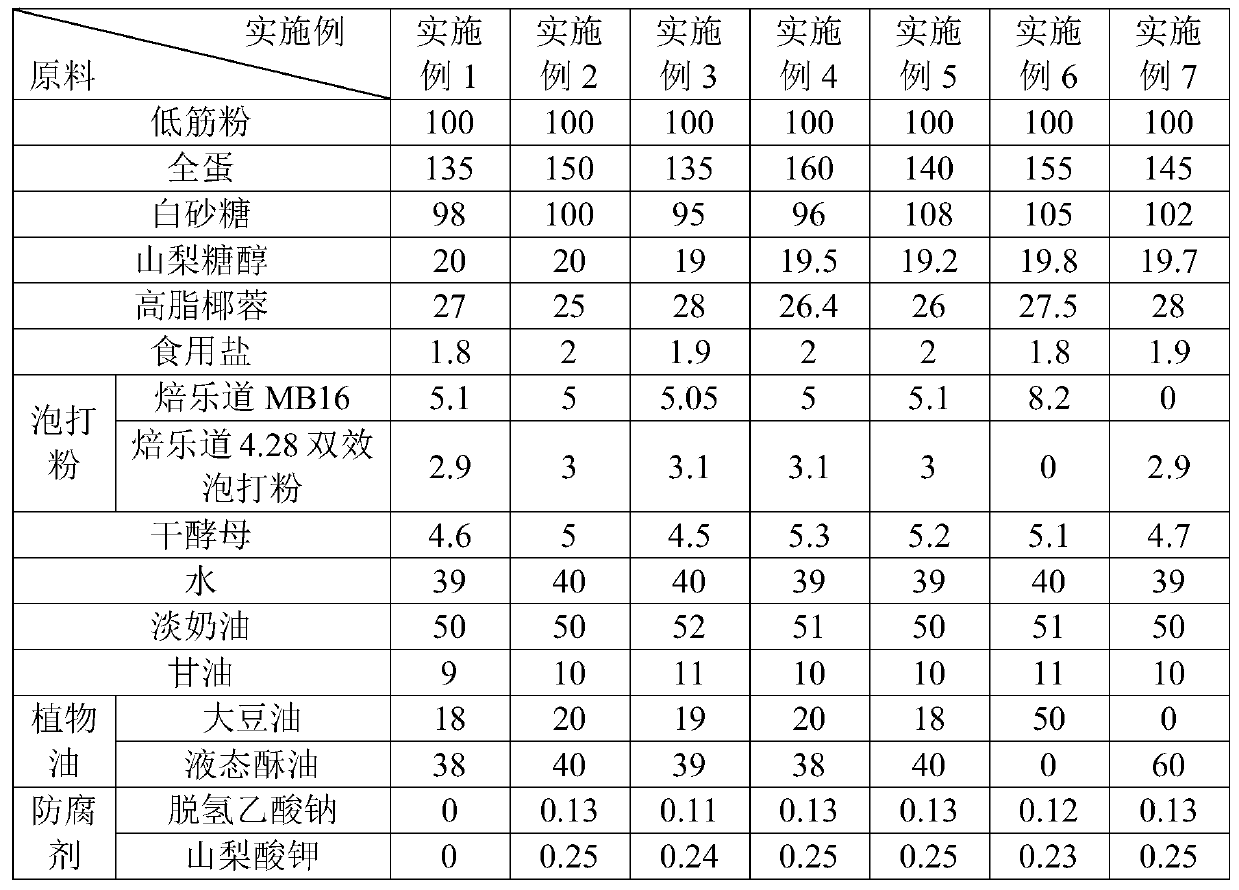

[0070] Embodiment 2-7: A fermented cake, the difference from Embodiment 1 is that the raw materials included and their corresponding qualities are shown in Table 1.

[0071] The raw material included in the embodiment 1-7 of table 1 and its corresponding quality (g)

[0072]

Embodiment 8

[0073] Embodiment 8: A fermented cake, the difference from Embodiment 3 is that Yanshan dry yeast is replaced with an equal amount of Brettanomyces castellus ZSM-001.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com