Double-beam laser processing optical system

A laser processing and optical system technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of high price, complicated optical path design, inconvenient installation and adjustment, etc., and achieve the effect of improving laser processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

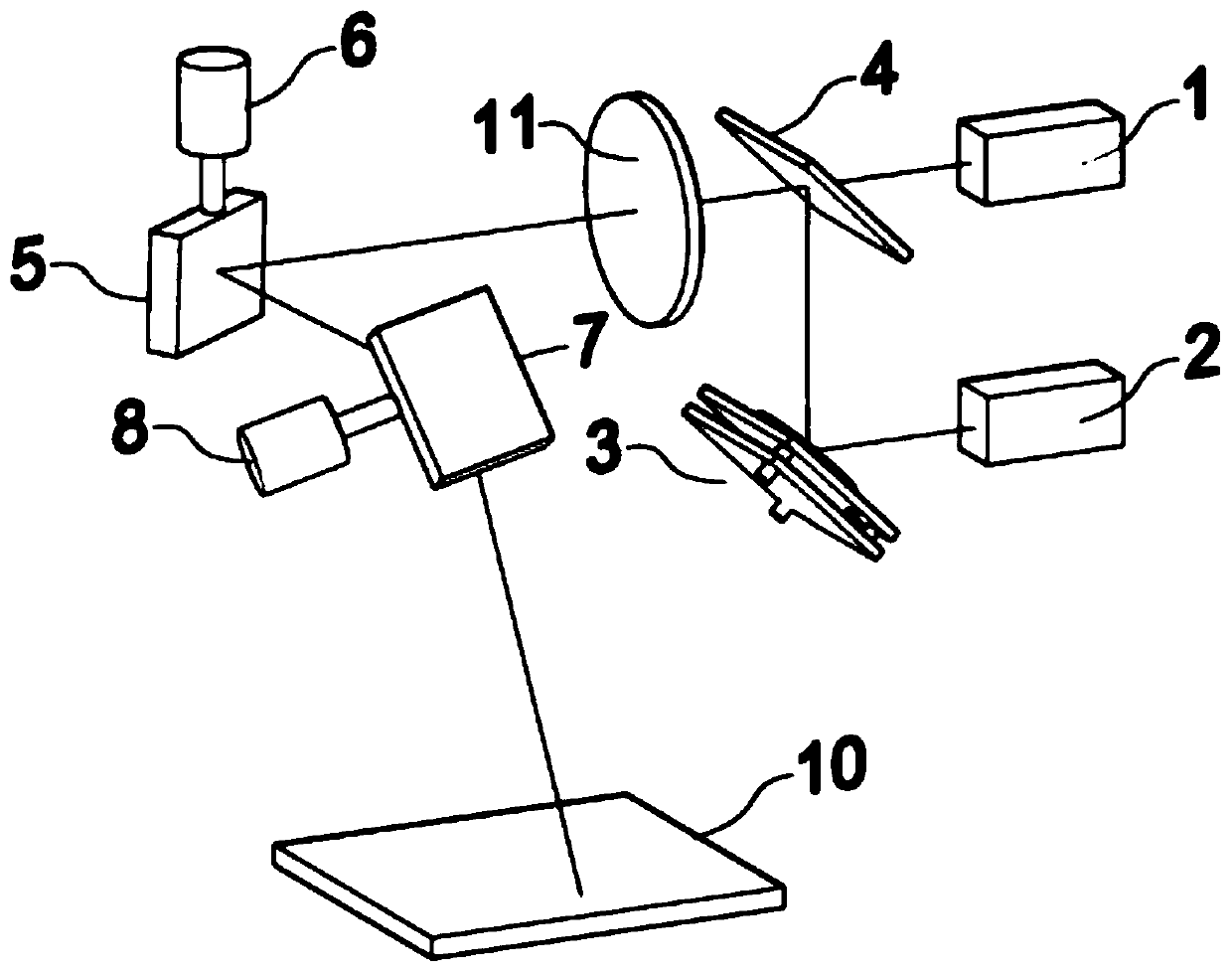

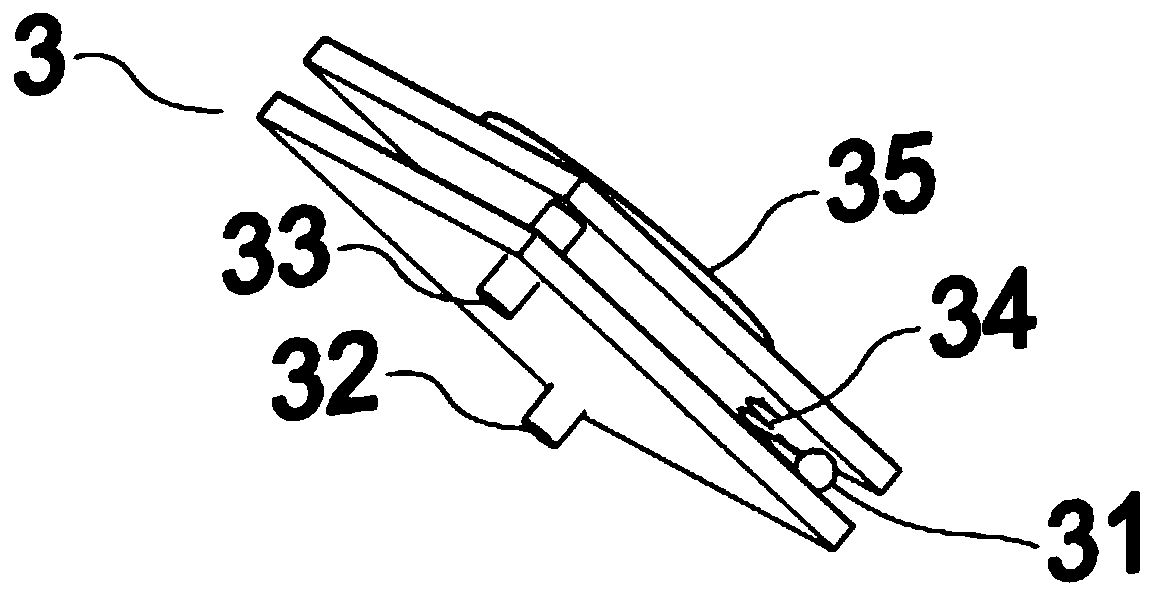

[0041] The schematic diagram of the first embodiment of the dual-beam laser processing optical system of the present invention is as follows figure 1 As shown, the two-beam laser processing optical system consists of a nanosecond pulsed fiber laser 1, a continuous semiconductor laser 2, a mirror 3 with an adjustable deflection direction, a wavelength beam combiner 4, a telephoto mirror 11, and a scanning galvanometer group (including X oscillating mirror 6, X scanning mirror 5 and Y oscillating mirror 8, Y scanning mirror 7) and workpiece 10 constitute, telephoto mirror 11 is placed on wavelength beam combiner 4 and comprises X oscillating mirror 6, X scanning mirror 5 and Y oscillating mirror Between the scanning galvanometer groups of the mirror 8 and the Y scanning mirror 7, the auxiliary laser emitted by the continuous semiconductor laser 2 is reflected by the reflector 3 with adjustable deflection direction and then enters the wavelength beam combiner 4, and the main laser...

Embodiment 2

[0046] The schematic diagram of the second embodiment of the double-beam laser processing optical system of the present invention is as follows Figure 5As shown, the double-beam laser processing optical system consists of a nanosecond pulsed fiber laser, a continuous semiconductor laser, a mirror with adjustable deflection direction, a wavelength beam combiner, a field mirror, including an X galvanometer X scanning mirror and a Y galvanometer Y The scanning galvanometer group of the scanning mirror and the workpiece are composed. The field mirror is placed between the scanning galvanometer group including the X galvanometer X scanning mirror and the Y galvanometer Y scanning mirror and the workpiece. The auxiliary laser emitted by the continuous semiconductor laser is adjustable and deflected. The incident wavelength beam combiner is reflected by the reflector in the direction, and the main laser emitted by the nanosecond pulse fiber laser is incident into the wavelength beam ...

Embodiment 3

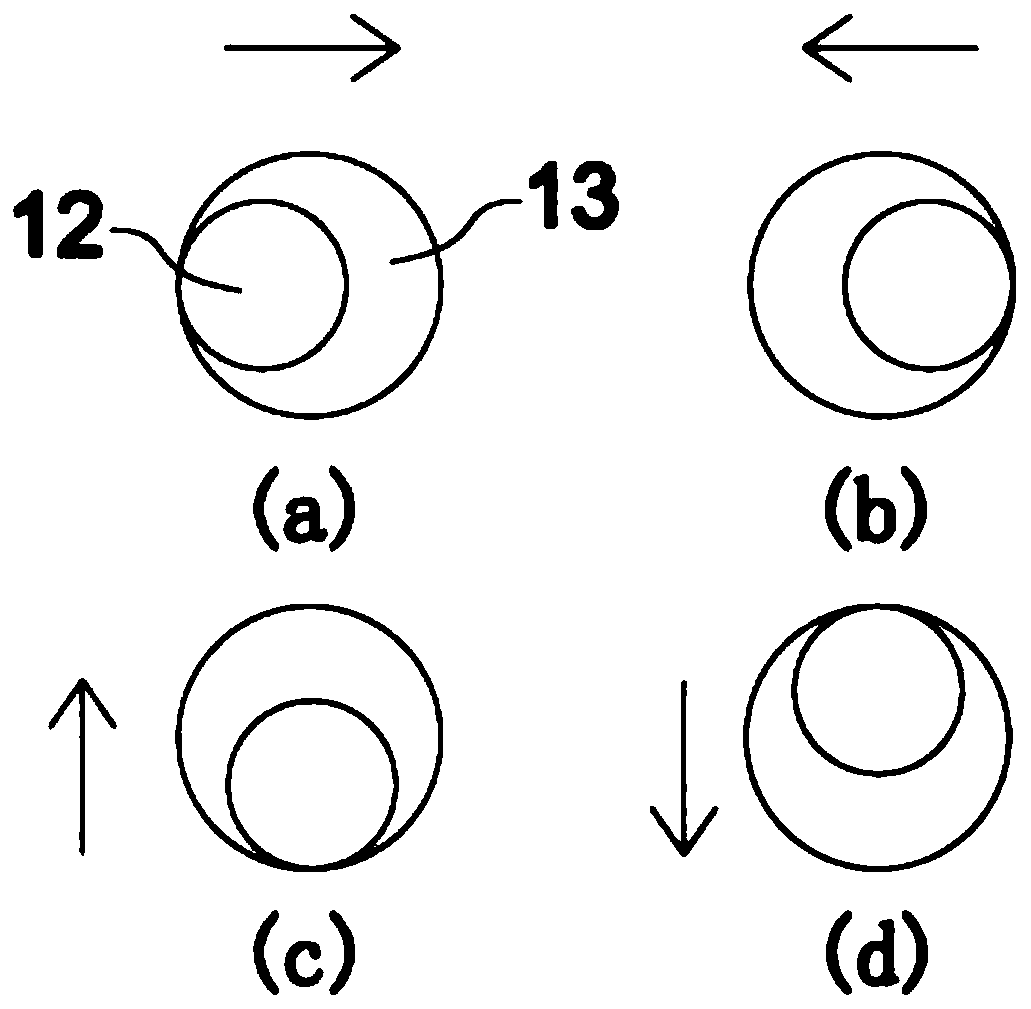

[0049] The schematic diagram of the third embodiment of the double-beam laser processing optical system of the present invention is as follows Figure 6 As shown, the difference from Embodiment 1 is that the scanning galvanometer group used only includes X galvanometers and X scanning mirrors. The common movement direction of the dual-beam laser on the workpiece can only move left and right. Taking the auxiliary laser focusing spot in front and the main laser focusing spot behind, which is used for preheating and auxiliary heating as an example, the positions of the main laser and the auxiliary laser on the workpiece are as follows: image 3 (a) and (b) shown. The double-beam laser processing optical system can be packaged and made into a hand-held or mechanical moving arm for laser cleaning. Others, such as the relative position control of the main laser and the auxiliary laser, and the structure of the mirror with adjustable deflection direction, etc. are consistent with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com