Multi-disc waxing machine

A technology of wax machine and mounting plate, which is applied in the direction of cleaning machinery, grinding machine parts, surface polishing machine tools, etc. It can solve the problems of reducing the relative speed between the polishing wheel and the surface of the workpiece, reducing the effect of polishing and waxing, etc. Achieve the effect of good operation consistency, simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

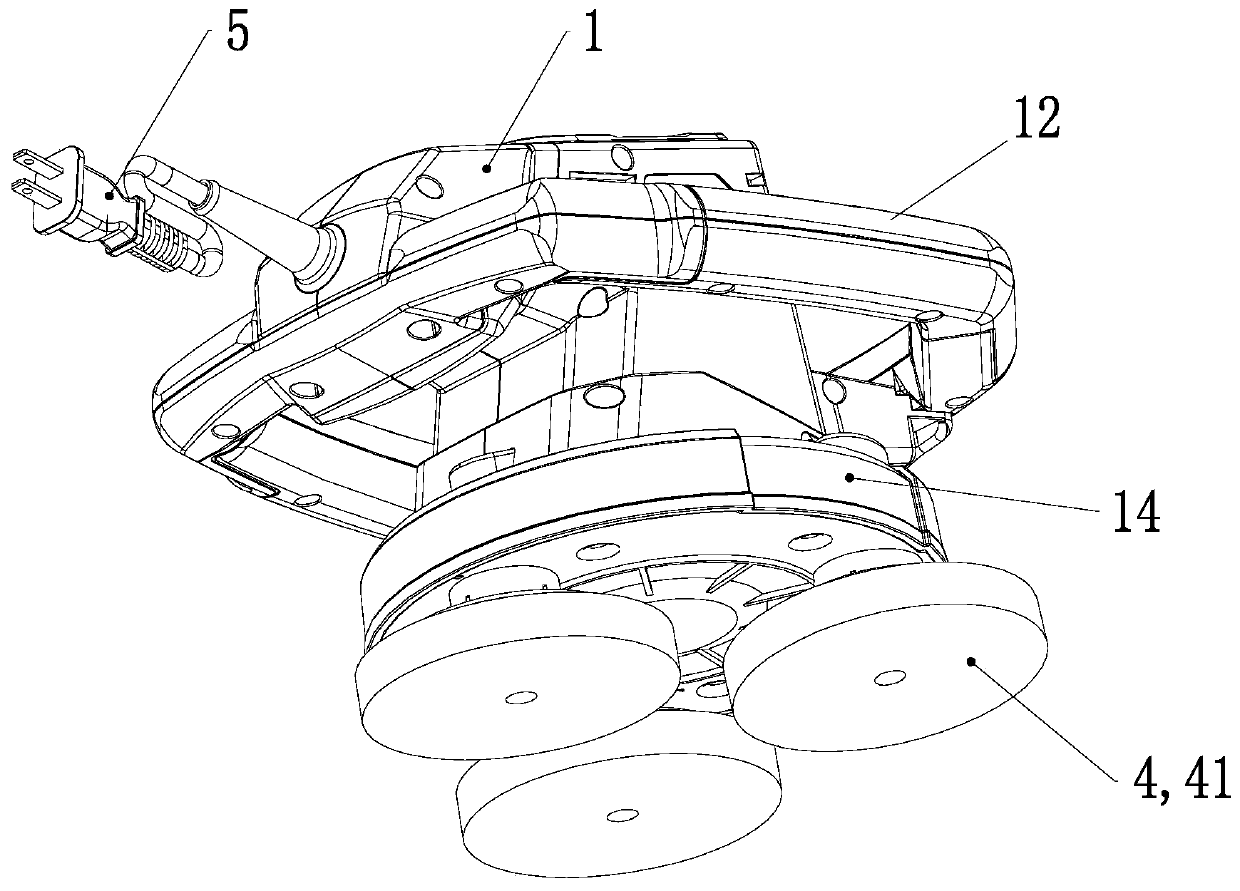

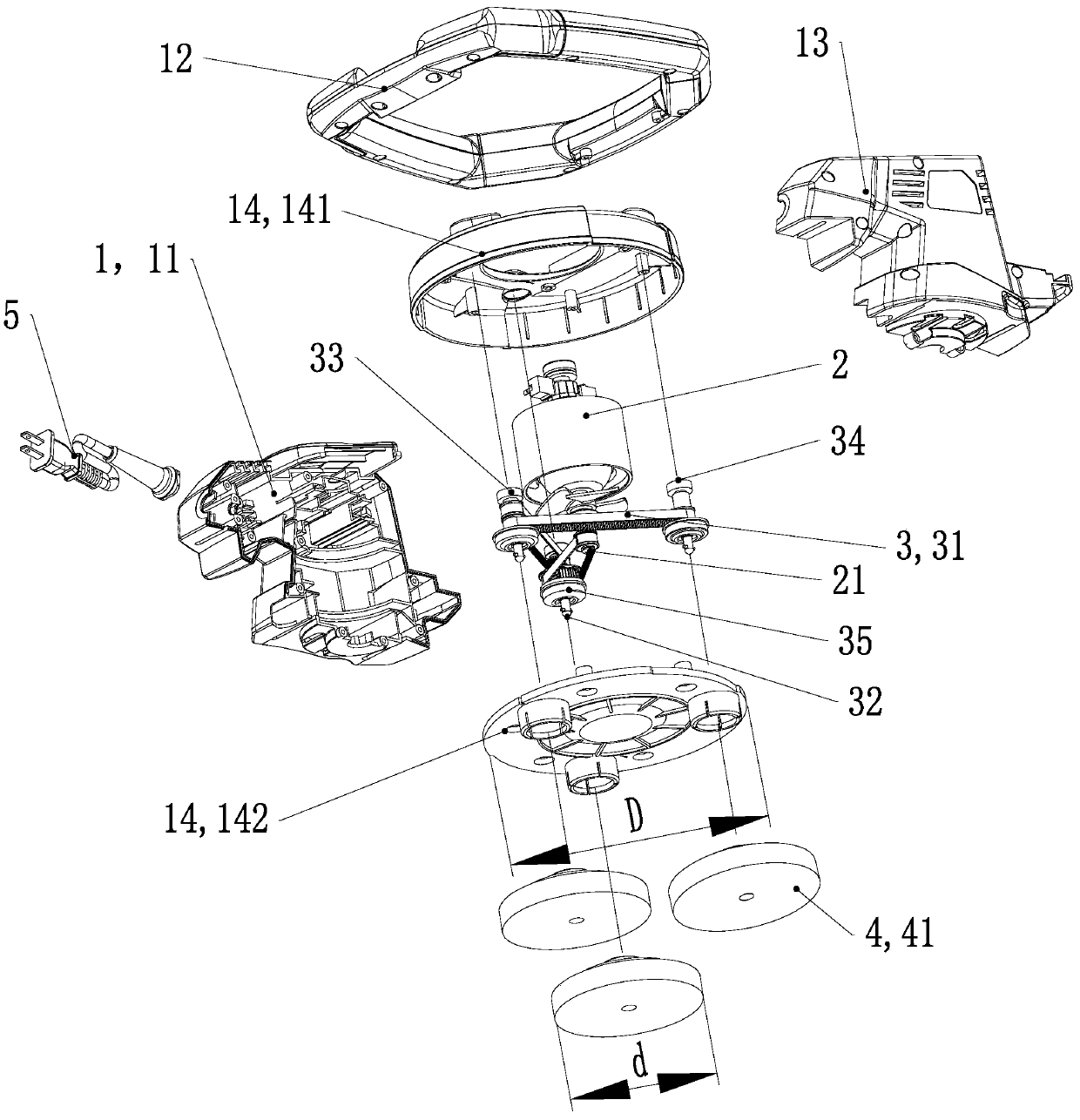

[0034] See Figure 1 to Figure 13 , The multi-disk waxing machine of the present invention includes a housing 1, a motor 2, a transmission assembly 3, a disc throwing assembly 4 and a power cord 5.

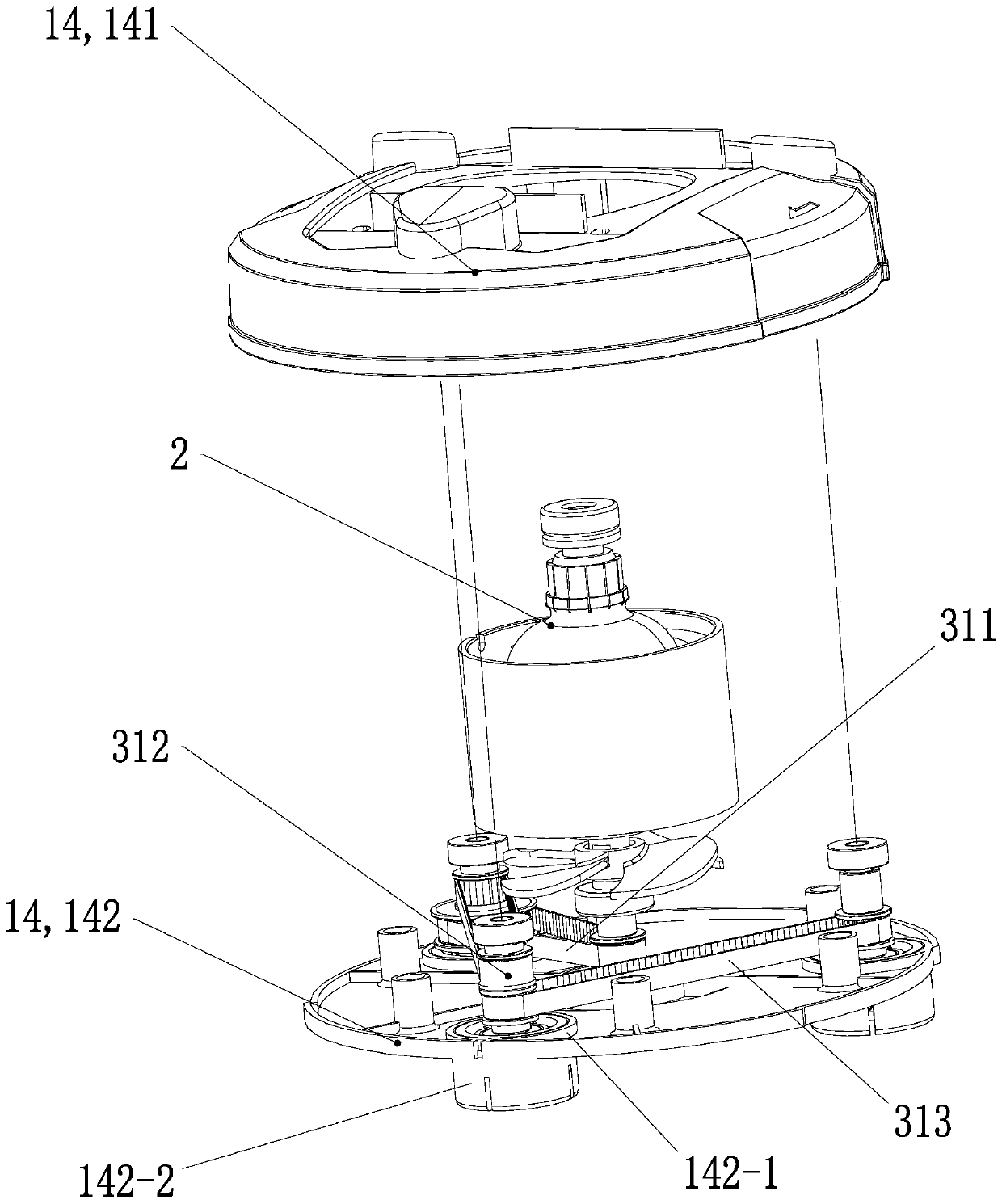

[0035] See Figure 1 to Figure 4 and Figure 10 to Figure 12 , the housing 1 includes a left housing 11, a handle 12, a right housing 13 and a mounting plate 14; the left housing 11 and the right housing 13 are fixedly connected to form a cavity structure, and the cavity has a downward opening. The handle 12 is ring-shaped, and the handle 12 is fixedly connected with the left housing 11 and the right housing 13 , and is arranged around the upper parts of the left housing 11 and the right housing 13 . The installation tray 14 includes an upper cover plate 141 of the installation tray and a lower base 142 of the installation tray. The lower base 142 of the installation disk is fixedly arranged on the lower part of the upper cover plate 141 of the installation disk from below, and...

Embodiment 2)

[0046] see Figure 15 , the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the transmission mode of this embodiment is a parallel transmission mode, and the corresponding pulleys and belts are adjusted accordingly according to the transmission mode: the parallel transmission mode is The motor output shaft 21 simultaneously drives a corresponding throwing disc 41 to rotate through three belts.

Embodiment 3)

[0048] see Figure 16 , the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the transmission mode of this embodiment is an envelope transmission mode, and the corresponding pulleys and belts are adjusted accordingly according to the transmission mode: the envelope transmission The method is that the motor output shaft 21 simultaneously drives three throwing discs 41 to rotate through one enveloping belt 314 . Both the inner and outer sides of the envelope belt 314 are provided with protruding teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com