Method for preparing calcium sulphosilicate-Belite-sulfoaluminate cement clinker at low temperature

A technology of sulphoaluminate cement and calcium sulphosilicate, which is applied in the field of materials, can solve the problems of high energy consumption and complex process, and achieve the effects of low energy consumption, lower calcination temperature, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing calcium sulfosilicate-belite-sulfoaluminate cement clinker at low temperature includes the following steps:

[0024] (1) Crush the siliceous raw material (steel slag), calcareous raw material (limestone), aluminum raw material (bauxite) and industrial gypsum (desulfurized gypsum) into particles less than 10mm, and then press 28.29:39.15:9.05:23.05 The mass ratio of the ingredients, ball milling (ball to material ratio 4:1, speed 150r / min), after 72h grinding (during the period, take out the mashed sinking material every 3h) to obtain raw material;

[0025] (2) Press the raw meal into square tablets under 3MPa, and then calcinate the square tablets at 1000°C. After holding for 1 hour, take out the rapid cooling, and then grind until the particles pass through a square hole sieve with an aperture of 80μm, and the sieve residue is less than 10%. Calcium sulfosilicate-belite-sulfoaluminate cement clinker is obtained.

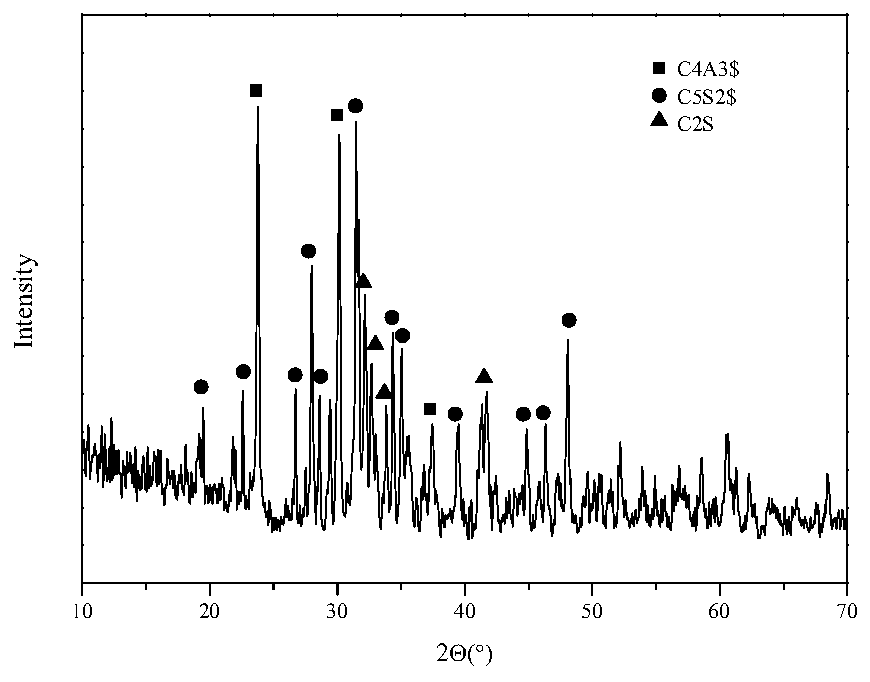

[0026] The XRD pattern of the prepared...

Embodiment 2

[0028] A method for preparing calcium sulfosilicate-belite-sulfoaluminate cement clinker at low temperature includes the following steps:

[0029] (1) Crush siliceous raw materials (coal gangue), calcareous raw materials (calcium slag), aluminum raw materials (aluminum slag) and industrial gypsum (desulfurized gypsum) into particles below 10mm, and then press 27.67:37.04:12.72: 22.57 mass ratio ingredients, ball milling (ball-to-material ratio 5:1, speed 250r / min), after grinding 48h (during the period, take out the mashed sinking material every 3h) to obtain raw meal;

[0030] (2) Press the raw meal into square tablets under 3MPa, and then calcinate the square tablets at 1100°C. After holding for 2h, take out the quench, and then grind until the particles pass through a square-hole sieve with an aperture of 80μm, and the sieve residue is less than 10%. Calcium sulfosilicate-belite-sulfoaluminate cement clinker is obtained.

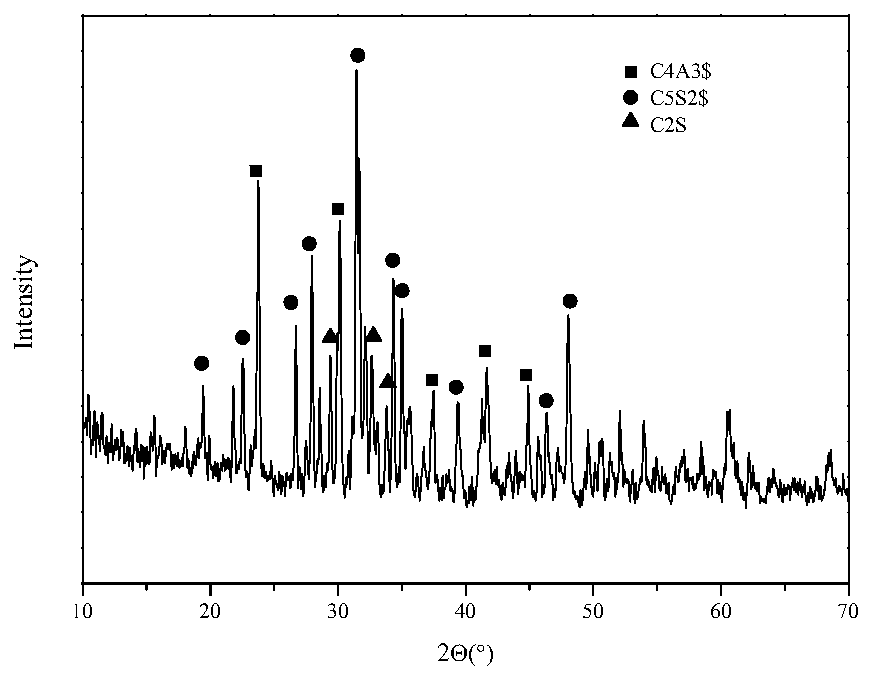

[0031] The XRD pattern of the prepared cement clinker is ...

Embodiment 3

[0033] A method for preparing calcium sulfosilicate-belite-sulfoaluminate cement clinker at low temperature includes the following steps:

[0034] (1) Crush the siliceous raw material (coal gangue), calcareous raw material (limestone), aluminum raw material (bauxite) and industrial gypsum (desulfurized gypsum) into particles below 10mm, and then press 38.75:19.72:19.78: 22.29 mass ratio ingredients, ball milling (ball-to-battery ratio 6:1, speed 350r / min), after grinding for 60h (during the period, take out the mashed sinking material every 3h) to obtain raw meal;

[0035] (2) Press the raw meal into square slices under 4MPa, calcinate the square slices at 1200°C, keep it for 2 hours, take out the quench, and then grind until the particles pass through a square-hole sieve with an aperture of 80μm, and the sieve residue is less than 10%. Obtain calcium sulfosilicate-belite-sulfoaluminate cement clinker.

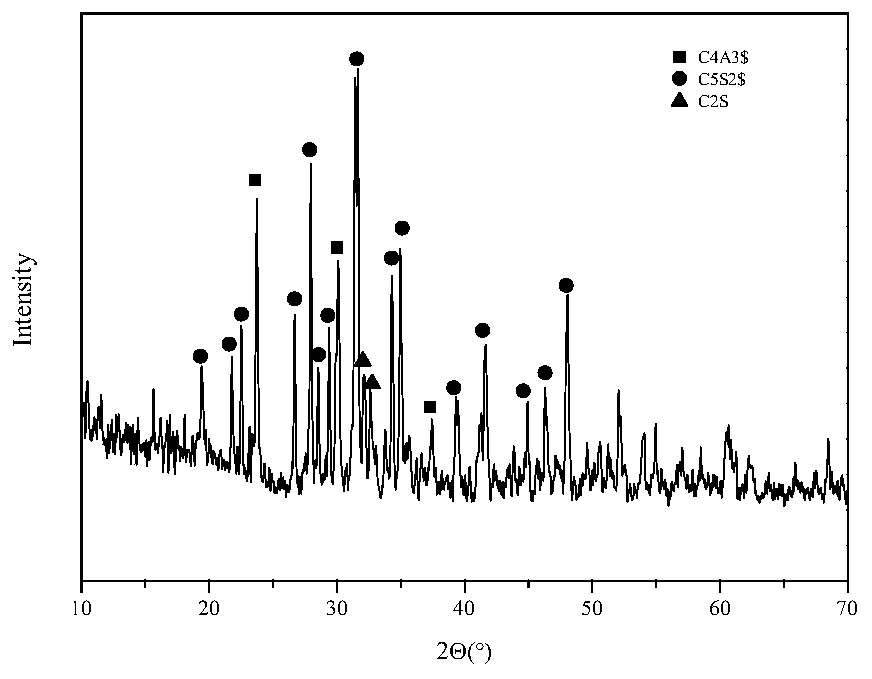

[0036] The XRD pattern of the prepared cement clinker is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com