Liquid alkali-free setting accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of building materials and can solve the problems of large rebound, poor stability, and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

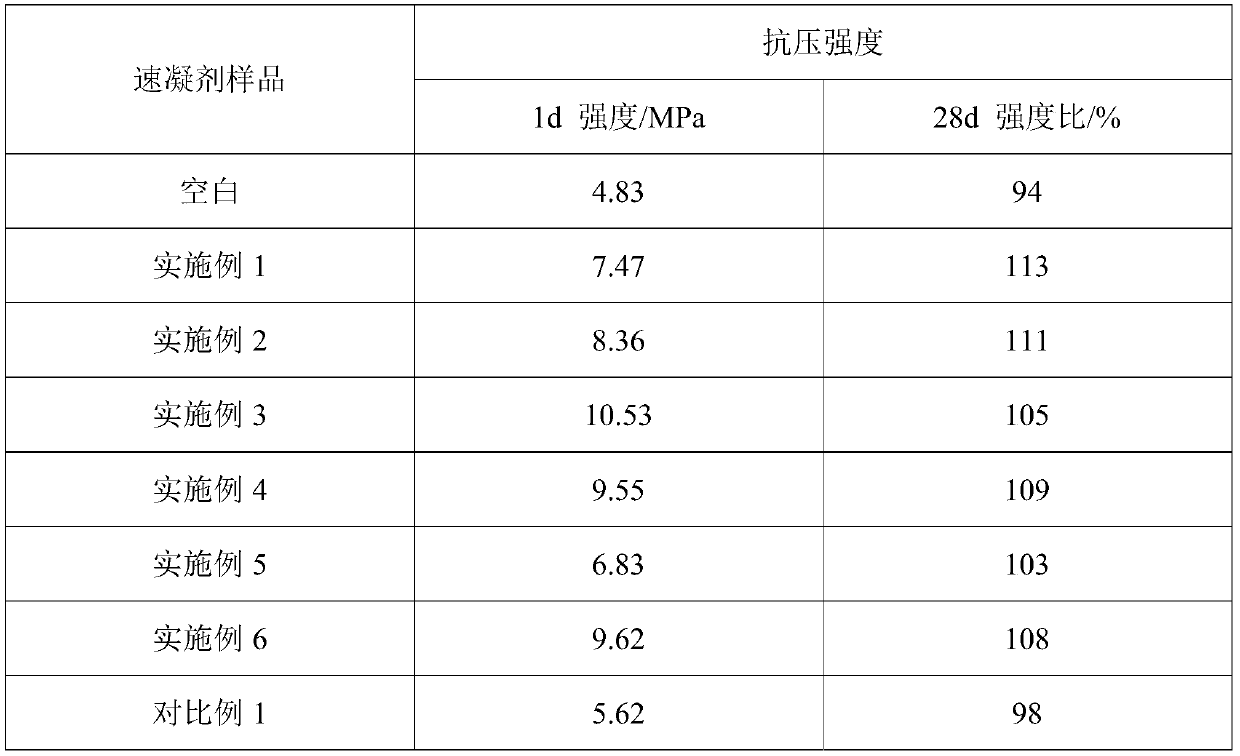

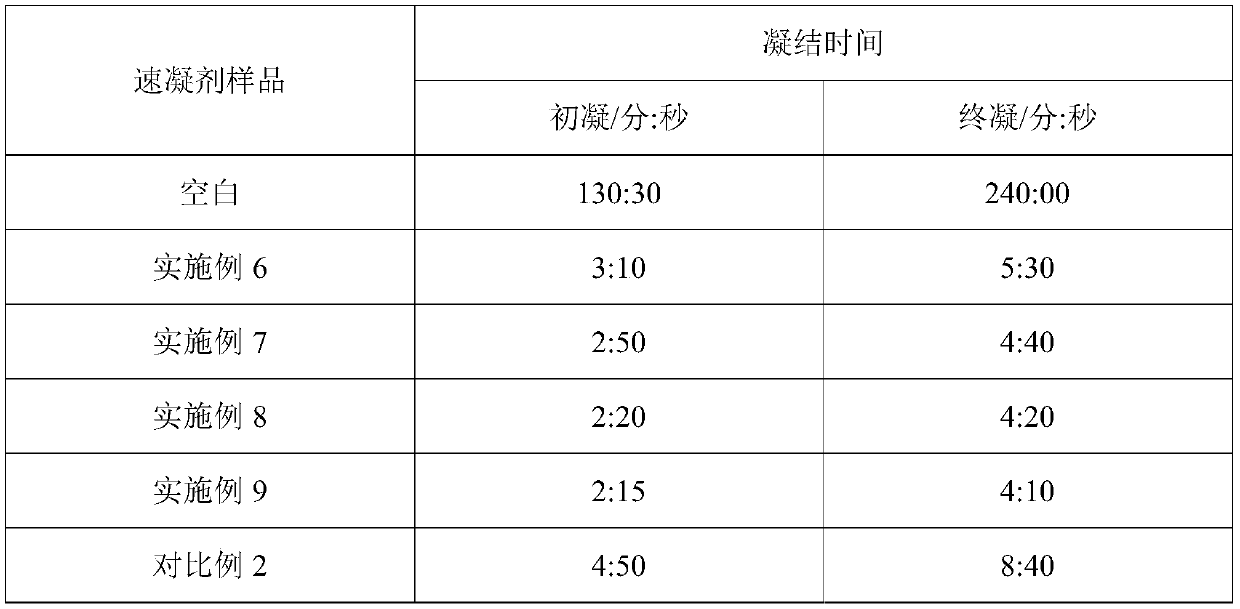

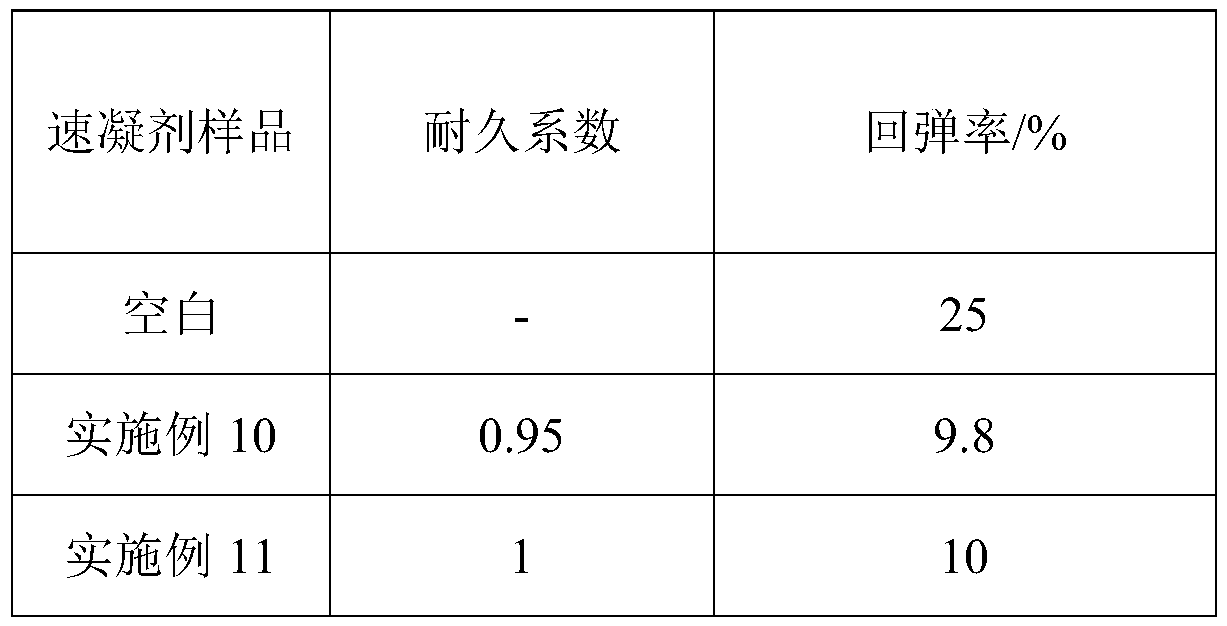

Examples

Embodiment 1

[0046] (1) At room temperature, 40% polyaluminum sulfate (Al 2 o 3 content of 10%) was dissolved in water, then 10% EDTA was added, stirred evenly, and reacted at 30-60°C for 1-2 hours to obtain a complex;

[0047] (2) Add 1% Al-MOF (pore volume is 1.39cm 3 / g, the specific surface area is 2757m 2 / g, the skeleton density is 0.45g / cm 3 ) stirred evenly, ultrasonic treatment for 15 minutes, to obtain a highly dispersed complex;

[0048] (3) under normal temperature, 3% bisphenol A epoxy vinyl ester resin and 1% bisphenol A epoxy resin (epoxy value 0.35) are dissolved in water, stir evenly, obtain organic tackifier;

[0049] (4) Add 5% aluminum hydroxide gel, 5% triethanolamine, 5% phosphoric acid and 0.5% sodium dodecylbenzenesulfonate into the highly dispersed complex, stir at 40-60°C for 30 minutes, and then Add an organic tackifier, 1% styrene, 0.2% di-tert-butyl peroxide, and 0.1% ethylenediamine, and react at 50-70°C for 1-3 hours to obtain a liquid alkali-free quick-...

Embodiment 2

[0051] (1) At room temperature, 40% polyaluminum sulfate (Al 2 o 3 content of 12%) was dissolved in water, then 10% EDTA was added, stirred evenly, and reacted at 30-60°C for 1-2 hours to obtain a complex;

[0052] (2) Add 1% Al-MOF (pore volume is 1.39cm 3 / g, the specific surface area is 2757m 2 / g, the skeleton density is 0.45g / cm 3 ) stirred evenly, ultrasonic treatment for 15 minutes, to obtain a highly dispersed complex;

[0053] (3) under normal temperature, 3% bisphenol A epoxy vinyl ester resin and 1% bisphenol A epoxy resin (epoxy value 0.35) are dissolved in water, stir evenly, obtain organic tackifier;

[0054] (4) Add 5% aluminum hydroxide gel, 5% triethanolamine, 5% phosphoric acid and 0.5% sodium dodecylbenzenesulfonate into the highly dispersed complex, stir at 40-60°C for 30 minutes, and then Add an organic tackifier, 1% styrene, 0.2% di-tert-butyl peroxide, and 0.1% ethylenediamine, and react at 50-70°C for 1-3 hours to obtain a liquid alkali-free quick-...

Embodiment 3

[0056] (1) At room temperature, 55% polyaluminum sulfate (Al 2 o 3 content of 12%) was dissolved in water, then 10% EDTA was added, stirred evenly, and reacted at 30-60°C for 1-2 hours to obtain a complex;

[0057] (2) Add 1% Al-MOF (pore volume is 1.39cm 3 / g, the specific surface area is 2757m 2 / g, the skeleton density is 0.45g / cm 3 ) stirred evenly, ultrasonic treatment for 15 minutes, to obtain a highly dispersed complex;

[0058] (3) under normal temperature, 3% bisphenol A epoxy vinyl ester resin and 1% bisphenol A epoxy resin (epoxy value 0.35) are dissolved in water, stir evenly, obtain organic tackifier;

[0059] (4) Add 5% aluminum hydroxide gel, 5% triethanolamine, 5% phosphoric acid and 0.5% sodium dodecylbenzenesulfonate into the highly dispersed complex, stir at 40-60°C for 30 minutes, and then Add an organic tackifier, 1% styrene, 0.2% di-tert-butyl peroxide, and 0.1% ethylenediamine, and react at 50-70°C for 1-3 hours to obtain a liquid alkali-free quick-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com