Performance regulation and forming method applicable to double-network intelligent hydrogel and product thereof

A hydrogel and dual-network technology, which is applied in the field of performance regulation and forming of dual-network intelligent hydrogels, can solve problems such as difficult forming, complex internal structure, and inability to achieve simple process, increase application range, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

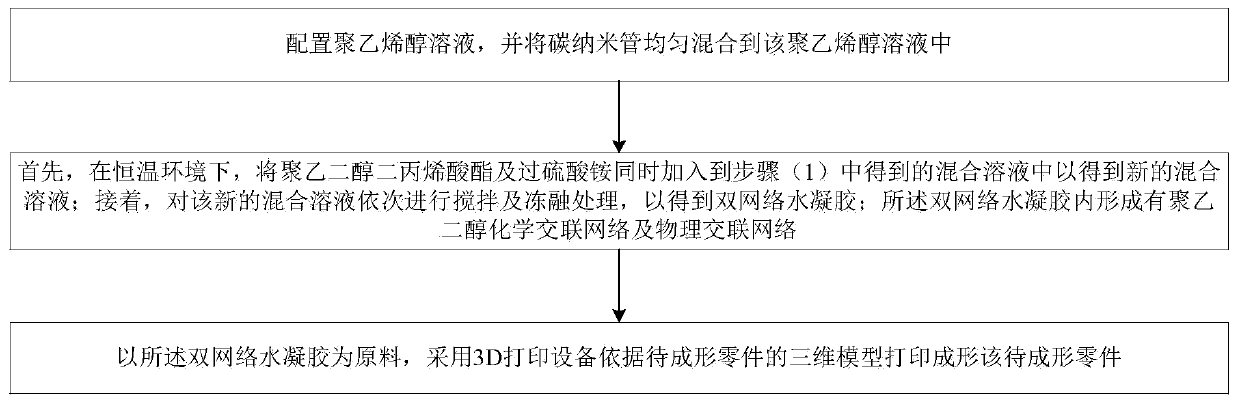

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 of the present invention provides a performance regulation and forming method suitable for dual-network smart hydrogels, the method comprising the following steps:

[0039] (1) Synthesis of polyethylene glycol diacrylate: 10 g of PEG powder was added into 100 ml of dichloromethane for dissolution, and then 2.02 g of triethylamine and 1.81 g of acryloyl chloride were added successively at room temperature. Then, the resulting mixture was stirred for 12 hours in an ice-water bath. Next, the triethylamine salt formed during the reaction was removed by filtration, the obtained polyethylene glycol diacrylate was added to 1 liter of diethyl ether cooled to 4°C, and the purification was repeated 4 times under the condition of isolation of air. process. Finally, the collected polyethylene glycol diacrylate was dried in a vacuum oven at 35°C for 20 hours.

[0040] (2) Synthesis of PVA-CNTs mixture: 30 g of PVA powder was added to 300 ml of distilled water at a tem...

Embodiment 2

[0045] The performance control and forming method suitable for dual-network smart hydrogel provided by Embodiment 2 of the present invention includes the following steps:

[0046] (1) Synthesis of polyethylene glycol diacrylate: 10 grams of PEG powder was added to 130 milliliters of dichloromethane for dissolution, and then 2.5 grams of triethylamine and 2 grams of acryloyl chloride were added successively at room temperature. Then, the resulting mixture was stirred for 9 hours in an ice-water bath. Next, the triethylamine salt formed during the reaction was removed by filtration, the obtained polyethylene glycol diacrylate was added to 1 liter of diethyl ether cooled to 2°C, and the purification was repeated 3 times in the absence of air. process. Finally, the collected polyethylene glycol diacrylate was dried in a vacuum oven at 35°C for 24 hours.

[0047] (2) Synthesis of PVA-CNTs mixture: 10 g of PVA powder was added to 300 ml of distilled water at a temperature of 90° C...

Embodiment 3

[0052] The performance control and forming method suitable for dual-network smart hydrogel provided by Embodiment 3 of the present invention includes the following steps:

[0053] (1) Synthesis of polyethylene glycol diacrylate: 10 grams of PEG powder was added to 135 milliliters of dichloromethane for dissolution, and then 3 grams of triethylamine and 2.2 grams of acryloyl chloride were added successively at room temperature. Then, the resulting mixture was stirred for 6 hours in an ice-water bath. Next, the triethylamine salt formed during the reaction was removed by filtration, and the obtained polyethylene glycol diacrylate was added to 1 liter of diethyl ether cooled to 2° C., and the purification was repeated twice in the absence of air. process. Finally, the collected polyethylene glycol diacrylate was dried in a vacuum oven at 35°C for 24 hours.

[0054] (2) Synthesis of PVA-CNTs mixture: 60 g of PVA powder was added to 300 ml of distilled water at a temperature of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com