Adjustable clamp holder

A clamper, adjustable technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem that the clamping area and contact area between the clamper and the slide rail cannot be adjusted, and increase the length , Good fixing performance and large clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The embodiment is basically as follows:

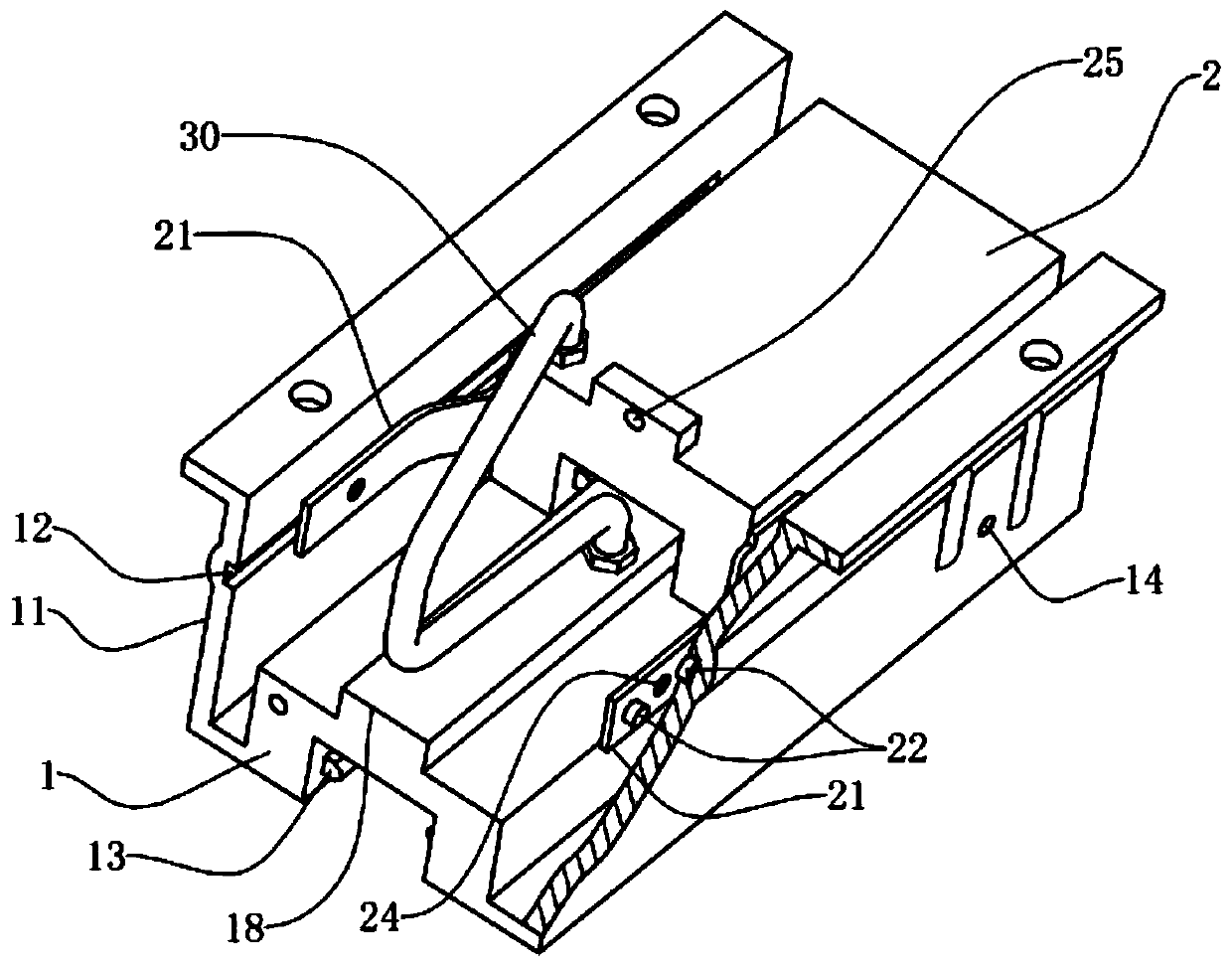

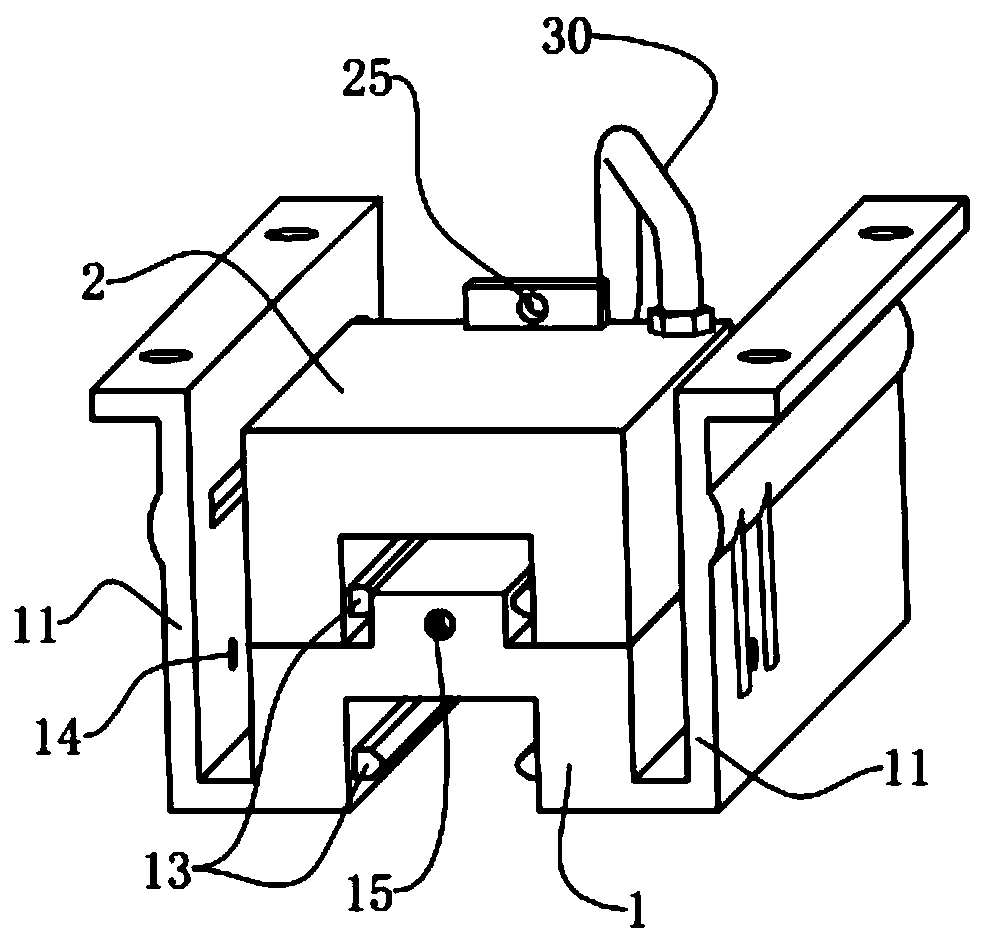

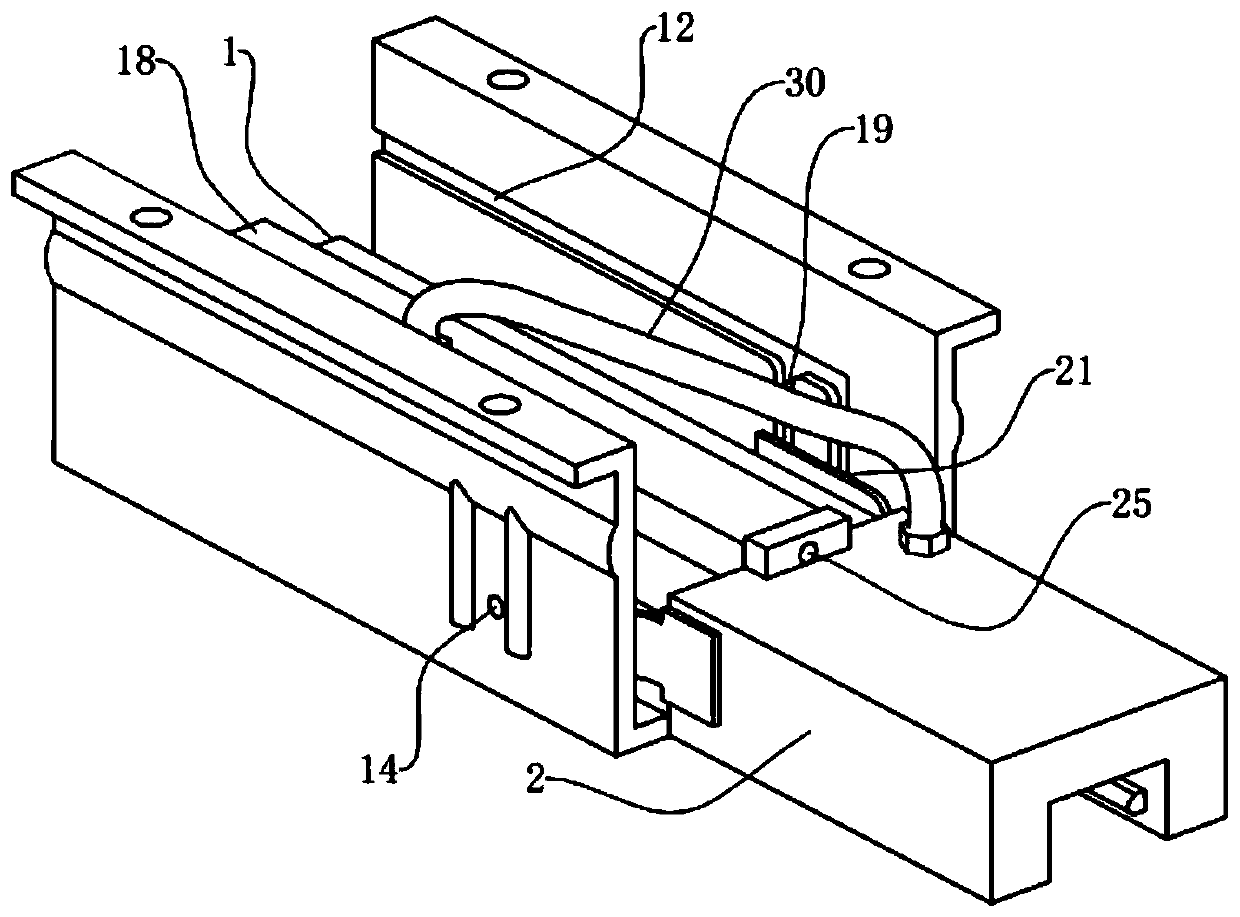

[0031] An adjustable gripper such as figure 1 As shown, it includes the main gripper 1 and the auxiliary gripper 2 with the same structure. The length of the auxiliary gripper 2 is about 1 / 2 of the length of the main gripper 1. Both sides of the main gripper 1 are fixedly connected with installation Plate 11, there is a gap between the mounting plate 11 and the side of the main holder 1, and the mounting plate 11 and the shell of the main holder 1 are integrally formed. The lower parts of the main gripper 1 and the auxiliary gripper 2 are provided with gripping grooves, and hydraulic oil chambers are arranged inside. The two hydraulic oil chambers are connected through a flexible hydraulic oil pipe 30. The hydraulic oil chamber of the main gripper 1 is connected to a hydraulic system. The side walls of the clamping groove are provided with clamping blocks 13, and the clamping blocks 13 are controlled by the hydraulic oil pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com