Turning flutter acceleration collection system and method based on machine vision

A machine vision and acquisition method technology, applied in metal processing equipment, metal processing mechanical parts, measuring/indicating equipment and other directions, can solve the problems of inaccurate acceleration signals, complex turning chatter inducements, and chatter effects, etc., to ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

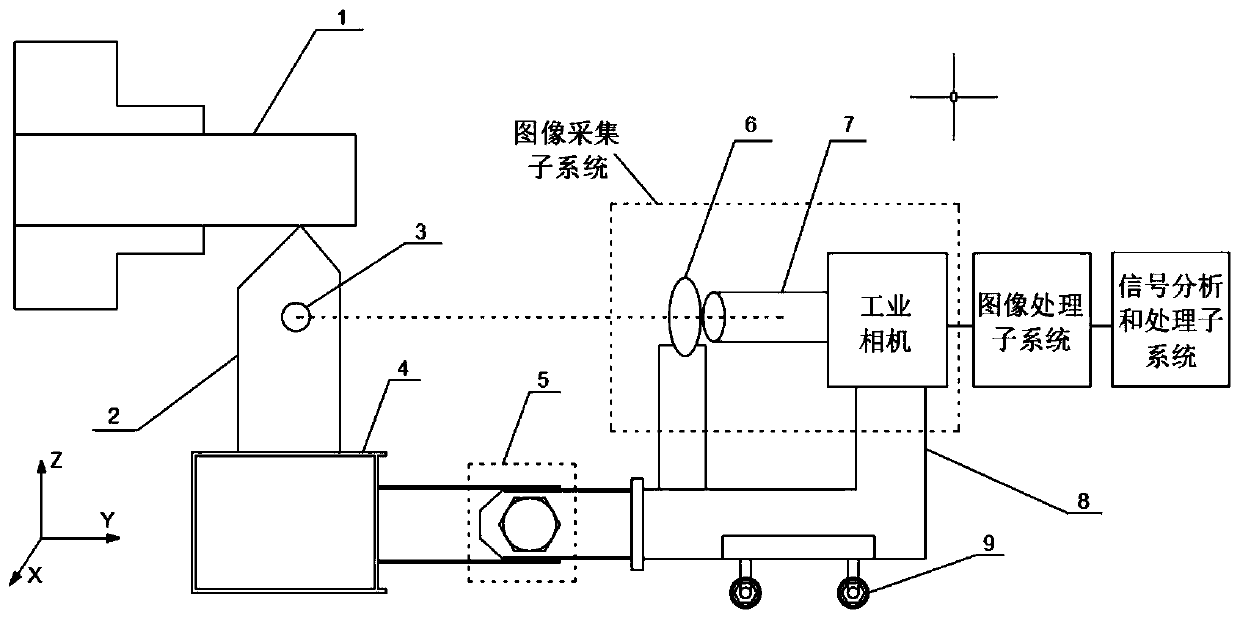

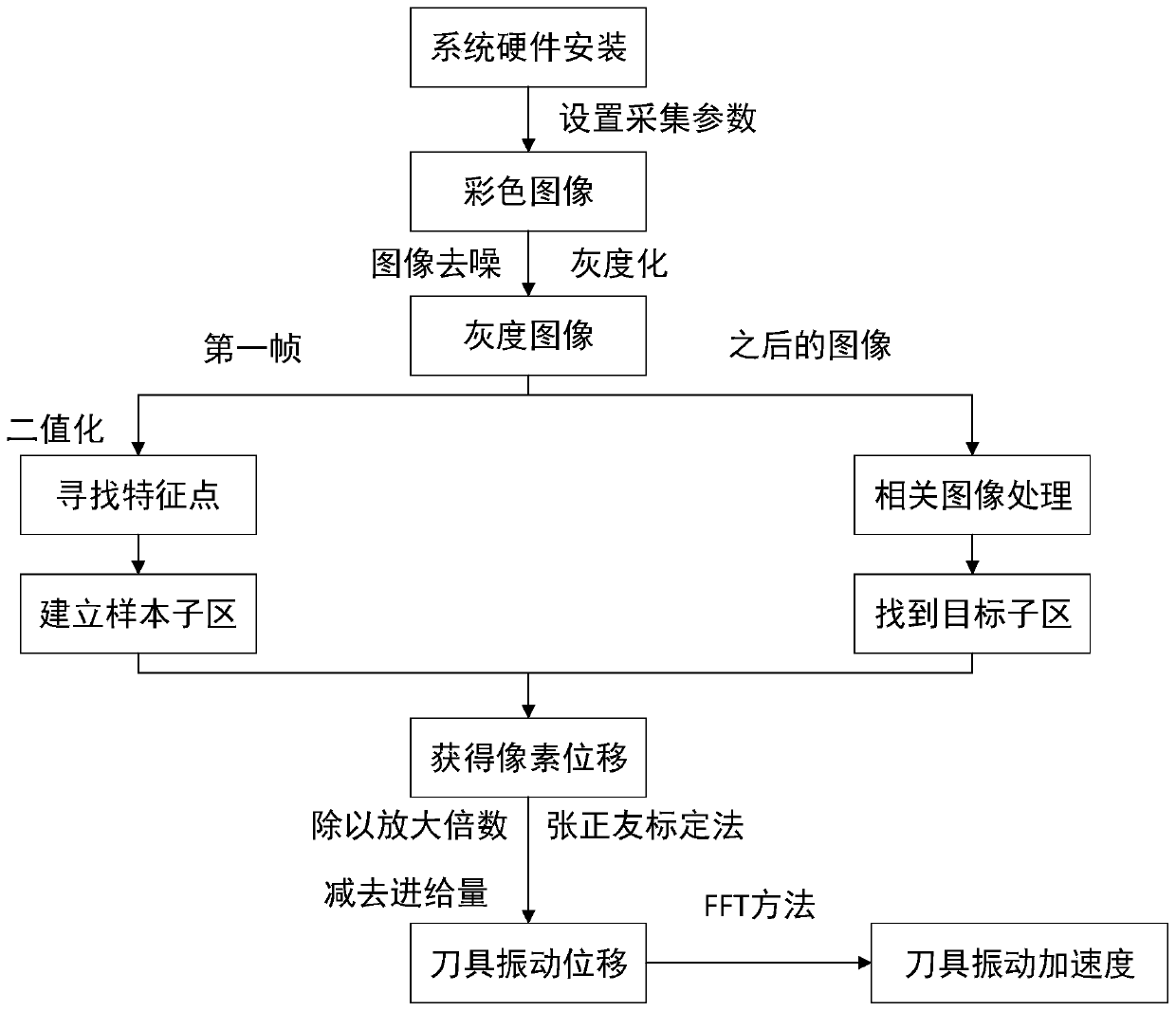

[0036] Such as figure 1 As shown, a machine vision-based turning chatter acceleration acquisition system includes:

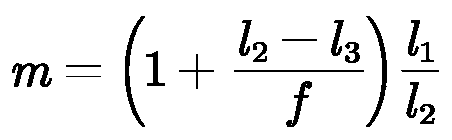

[0037] The image acquisition subsystem is set in the X direction shown in the figure; a circular marker 3 is set on the tool 2 as the characteristic area of the collected image, and the marker should be set on the plane of the tool as much as possible, and its diameter should not exceed Knives are attached figure 1 indicated by the Y-direction width of the A magnifying glass 6 is set on the connection between the camera lens 7 and the marker 3, wherein the distance between the magnifying glass and the camera lens is 0 for obtaining enlarged and clear images; flexible connection, in the attached figure 1 The Y direction shown is in a linked state, and the Z direction can move freely, so as to ensure that the camera lens 7, the magnifying glass 6 and the marker 3 are in the vicinity when the tool 2 moves axially. figure 1 The shown X direction is always on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com