Coaxial Powder Feed Nozzles for Strip Spots

A coaxial powder feeding and nozzle technology, applied in coating installation, process efficiency improvement, processing and manufacturing, etc., can solve problems such as application limitations and inability to directly use semiconductor lasers, to prevent high temperature oxidation, improve laser melting, etc. The effect of improving the coating efficiency and improving the coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

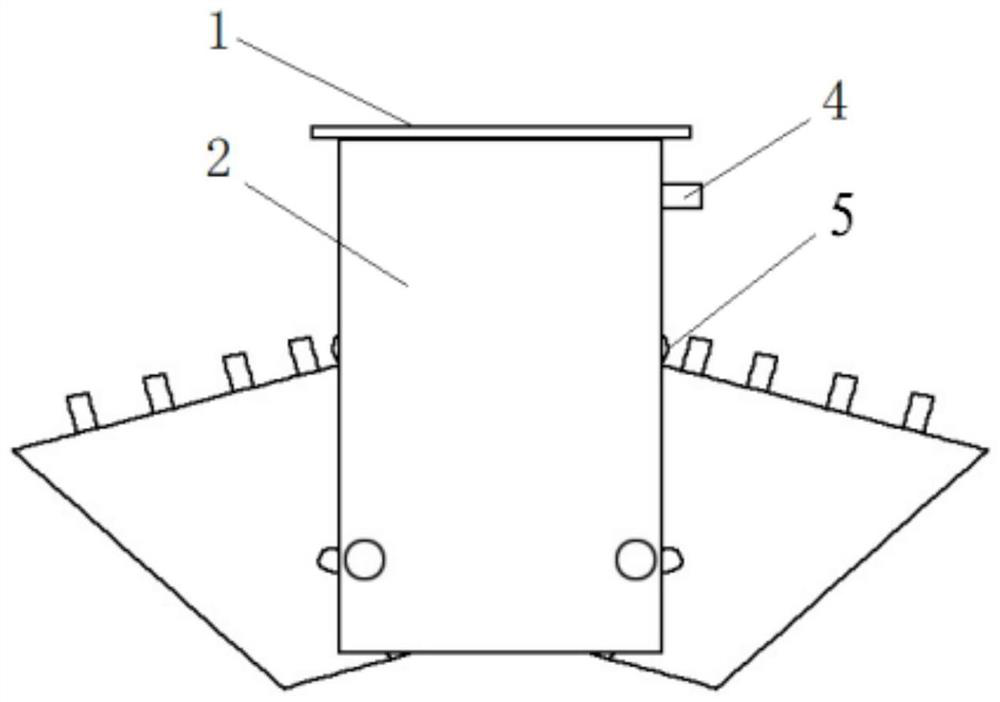

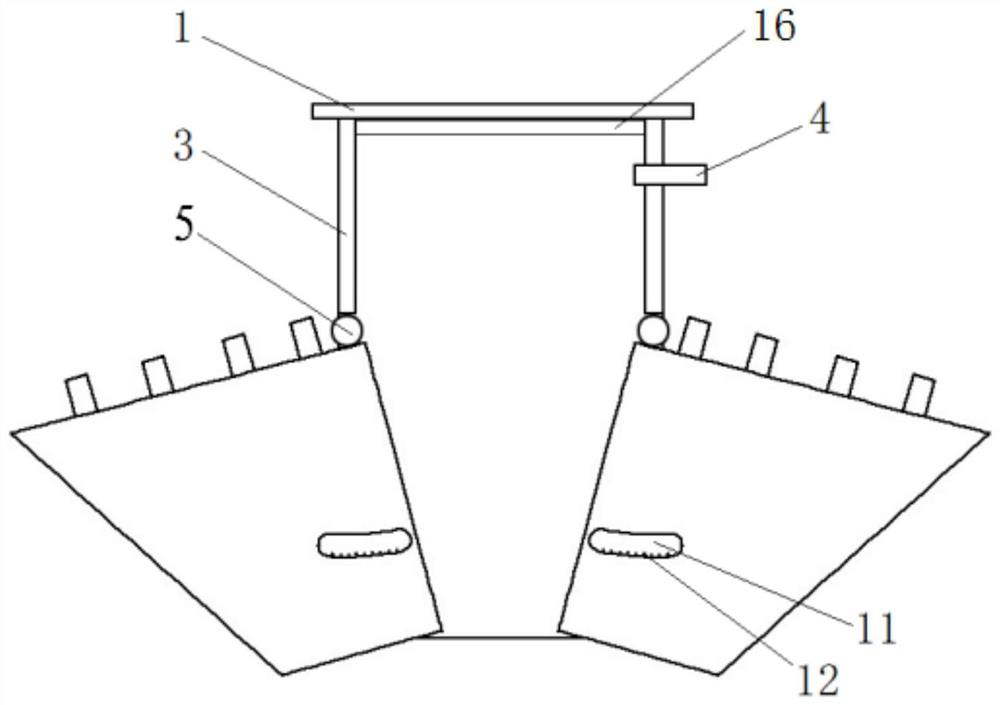

[0058] In this embodiment, a semiconductor laser with an output wavelength of 975 nm, an output power of 12 kW, and an output spot width of 36 mm is used. The connecting bracket is made of a 2 mm stainless steel plate to form a rectangular box structure with an inner width of 30 mm and a length of 50 mm. The vertical baffle is 3 high. It is 30mm, the inner protective gas inlet is set at the center of one side of the longitudinal baffle 3, the inner diameter is Ф6mm, the height of the lateral baffle 2 is 70mm, and a hole is opened at a height of 10mm from the side 2mm for the installation of manual knobs or shafts (of course also A micro stepping motor can be used), and a rotating shaft, namely the rotating shaft connector 5, is installed under the longitudinal baffle 3.

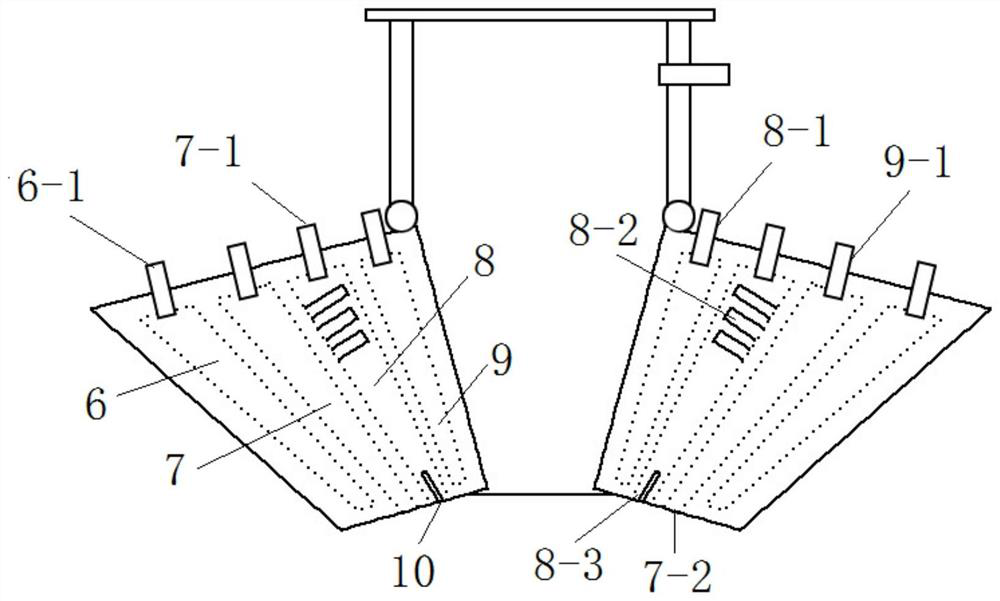

[0059] The single-side nozzle is made of red copper material with good thermal conductivity. The powder inlet port 8-1 is made of 3, which are located at 15mm, 25mm, and 35mm respectively. The diameter is Ф4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com