Encapsulation method of flexible solar cell module coil

A technology of solar cells and encapsulation methods, applied to electrical components, electronic equipment, chemical instruments and methods, etc., can solve the problems of low heating efficiency and achieve high heating efficiency, small heat loss, and good encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

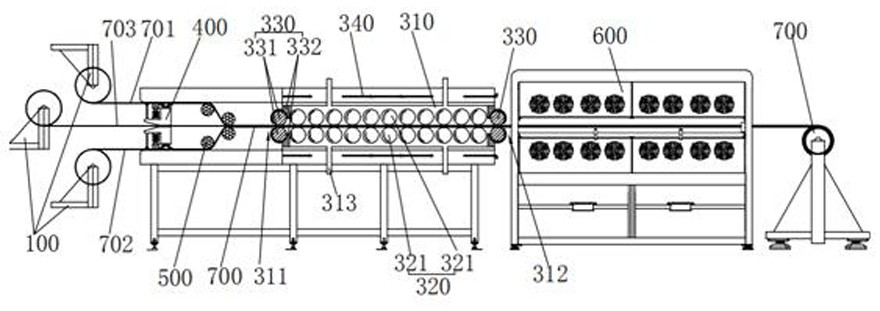

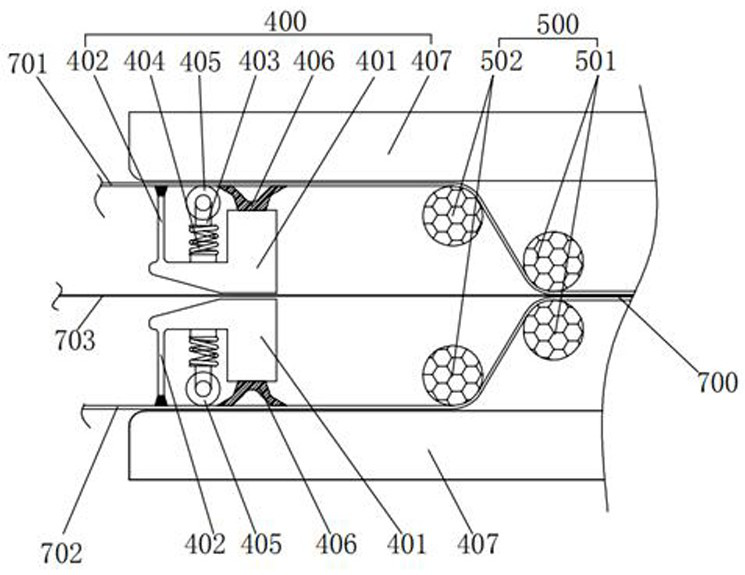

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals.

[0028] A method for encapsulating flexible solar cell module rolls, using a single-component organic silicone glue to bond each layer of material in the module, and pressing the module 700 sequentially through multiple sets of hot pressing rollers 320, and the module 700 is extruded During the heating process, it is vacuumed at the same time. Preferably, keep the vacuum at -0.8×10 when vacuuming 5 Pa to -0.6×10 5 Pa between. The temperature of the pressing roller group 320 rises sequentially, from 50±10°C to 100±10°C, the temperature difference between the hot rollers is 1-2°C, the rolling pressure is 500-750N / pair, and the vacuuming time is 30-40 minutes , the temperature of the pressure roller group located in the front is low, the glue can be gradually heated to soften, the glue is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com