Novel direct current smelting furnace

An electric furnace, a new technology, applied in the field of electric arc furnace, can solve the problem of unresolved load matching between the DC power supply device and the electric furnace molten pool, uneven power distribution of the electric furnace molten pool, high ore consumption per ton of products and high power consumption. , to achieve the effect of improving the actual industrial operation value, enhancing the overcurrent capability of the electrode, and high natural power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

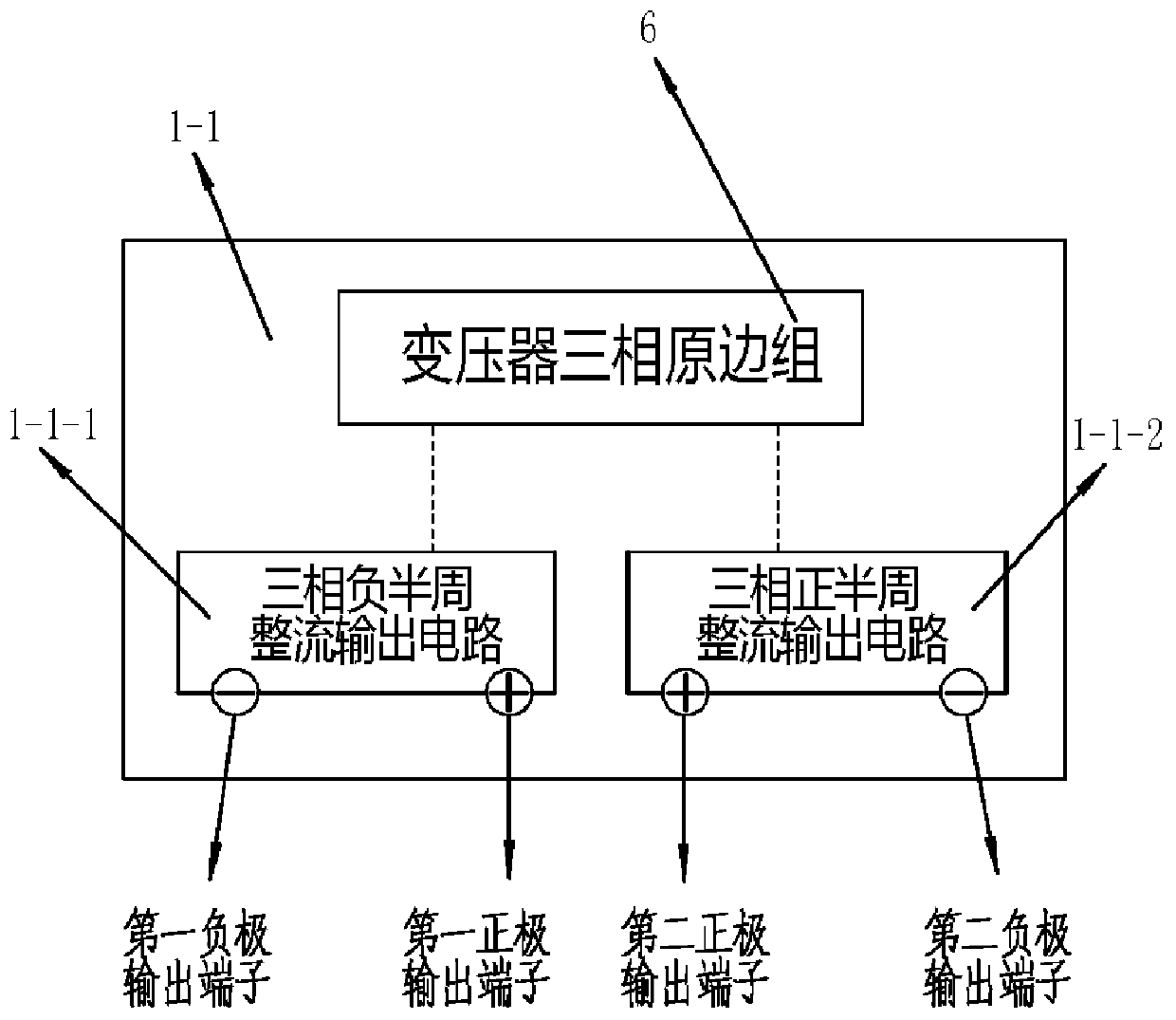

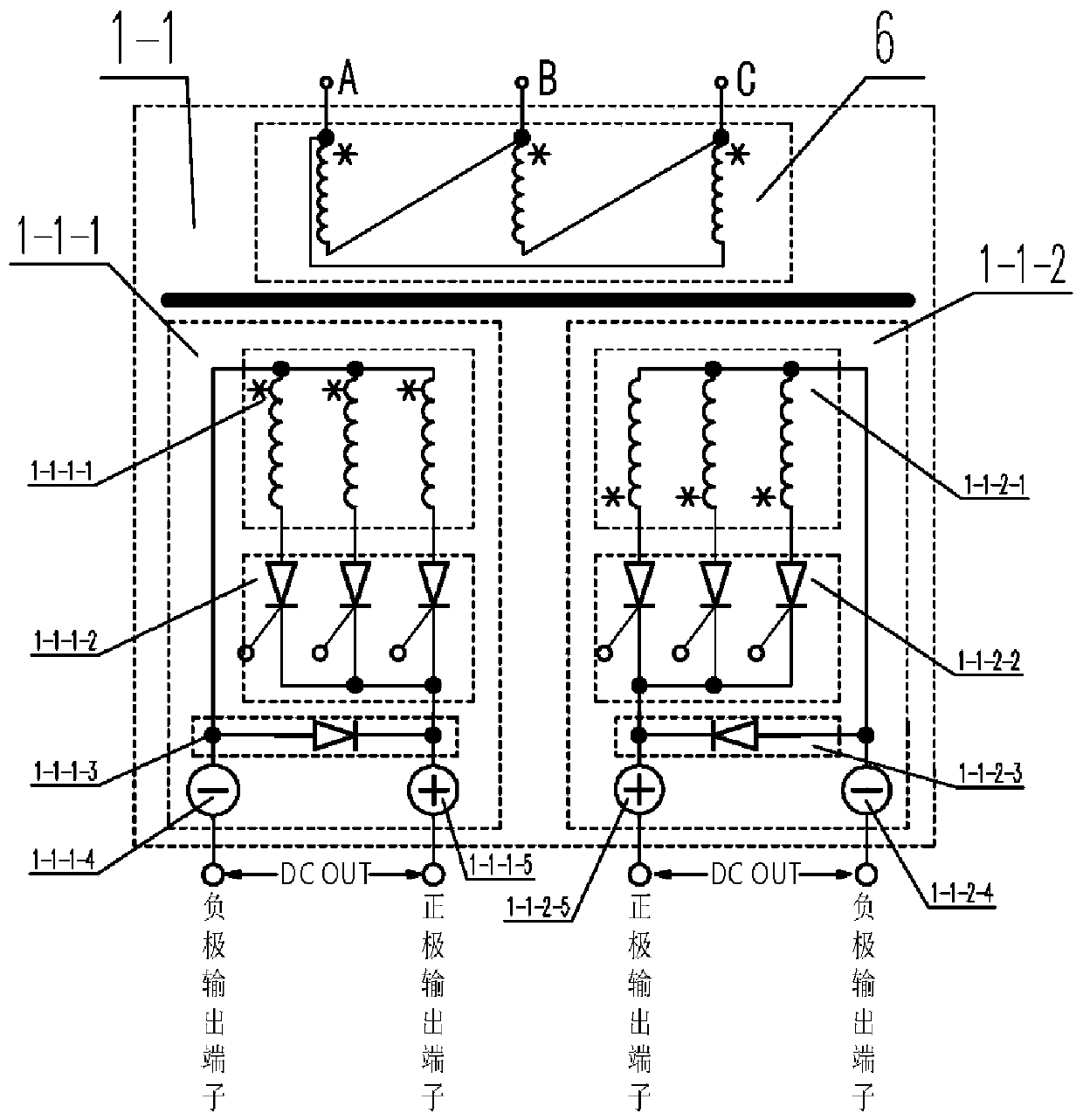

[0060] Example 1, combined with Figure 10 ~ Figure 11 As shown, when the total number of electrodes of the multi-load layout device 3 is four, the number of double-circuit DC power supply groups is two, and the two double-circuit DC power supply groups can use the first double-circuit DC power supply group 1-1 and the second double-circuit DC power supply group 1-1. Loop DC power supply group 1-2 indicates that the first double-loop DC power supply group 1-1 includes a three-phase negative half-cycle rectification output circuit 1-1-1 and a three-phase positive half-cycle rectification output circuit 1-1-2, and the second double-loop The DC power supply group 1-2 includes a three-phase negative half-cycle rectification output circuit 1-2-1 and a three-phase positive half-cycle rectification output circuit 1-2-2, and the four electrodes respectively use No. 1 electrode 3-1 and No. 2 electrode 3- 2. No. 3 electrode 3-3 and No. 4 electrode 3-4 indicate that No. 1 electrode 3-1 a...

example 2

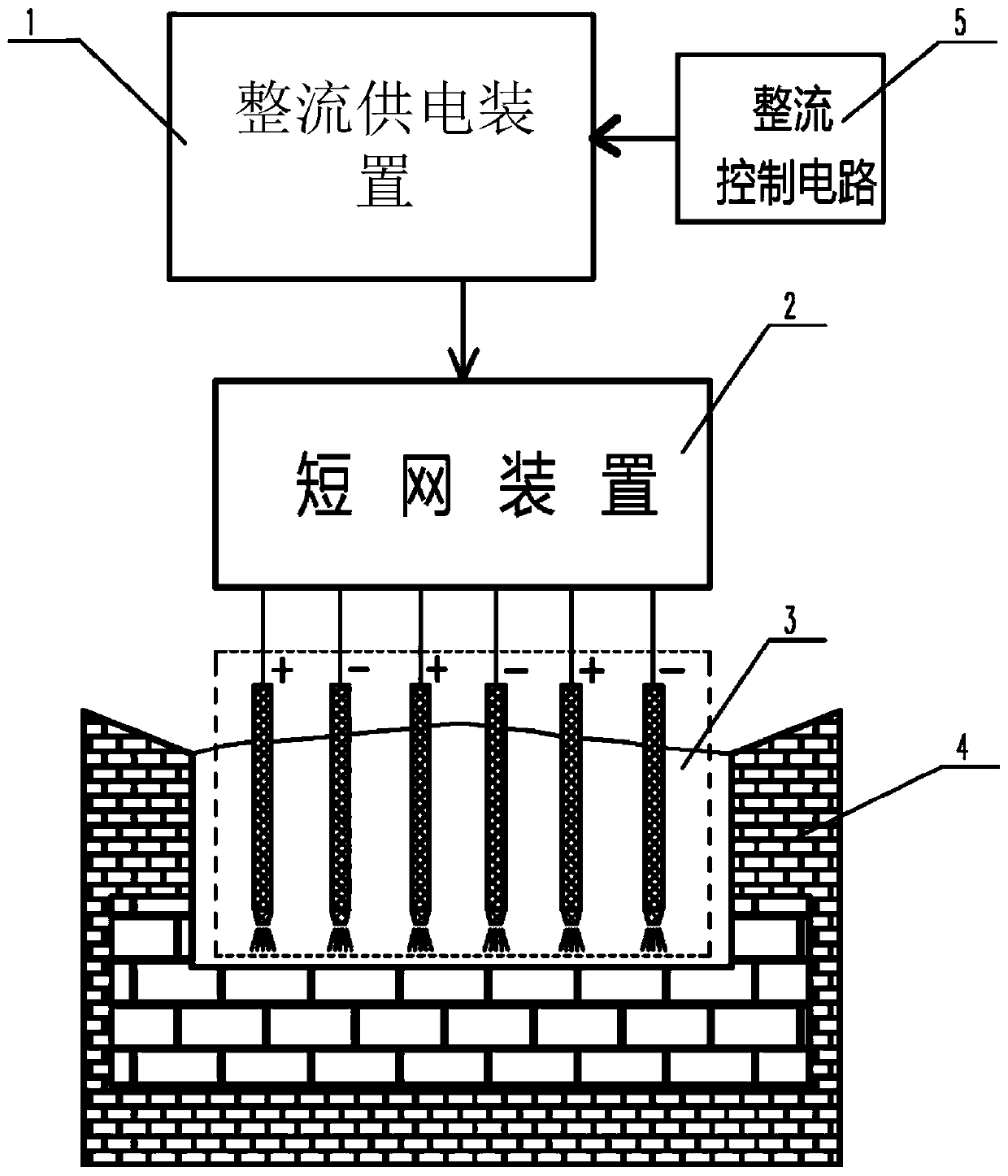

[0067] Example 2, combined with Figure 12 to Figure 15As shown, when the total number of electrodes of the multi-load layout device 3 is 6, the number of double-circuit DC power supply groups is 3, and the three double-circuit DC power supply groups can use the first double-circuit DC power supply group 1-1, the second double-circuit DC power supply group The loop DC power supply group 1-2 and the third double-loop DC power supply group 1-3 indicate that the first double-loop DC power supply group 1-1 includes a three-phase negative half-cycle rectification output circuit 1-1-1 and a three-phase positive half-cycle rectification output circuit Circuit 1-1-2, the second double-circuit DC power supply group 1-2 includes a three-phase negative half-cycle rectification output circuit 1-2-1 and a three-phase positive half-cycle rectification output circuit 1-2-2, the third double-circuit DC power supply Group 1-3 includes a three-phase negative half-cycle rectification output circ...

example 3

[0076] Example 3, combined with Figure 16 ~ Figure 18 As shown, when the total number of electrodes of the multi-load layout device 3 is 8, the number of dual-circuit DC power supply groups is 4, and the 4 dual-circuit DC power supply groups can use the first dual-circuit DC power supply group 1-1, the second dual-circuit DC power supply group The loop DC power supply group 1-2, the third double-loop DC power supply group 1-3, and the fourth double-loop DC power supply group 1-4 indicate that the 8 electrodes respectively use No. 1 electrode 3-1, No. 2 electrode 3-2, No. 3 electrode 3-3, No. 4 electrode 3-4, No. 5 electrode 3-5, No. 6 electrode 3-6, No. 7 electrode 3-7, No. 8 electrode 3-8, among them, No. 1 electrode 3- 1, No. 3 electrodes 3-3, No. 5 electrodes 3-5, No. 7 electrodes 3-7 are positive electrodes, No. 2 electrodes 3-2, No. 4 electrodes 3-4, No. 6 electrodes 3-6, No. 8 Electrode 3-8 is a negative polarity electrode, No. 1 electrode 3-1 is adjacent to No. 2 elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com