Sintering system

A technology of sintering machine and flue gas, which is applied in the field of sintering system, can solve the problems of inability to reduce pollutant emission and ensure the quality of sinter ore, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

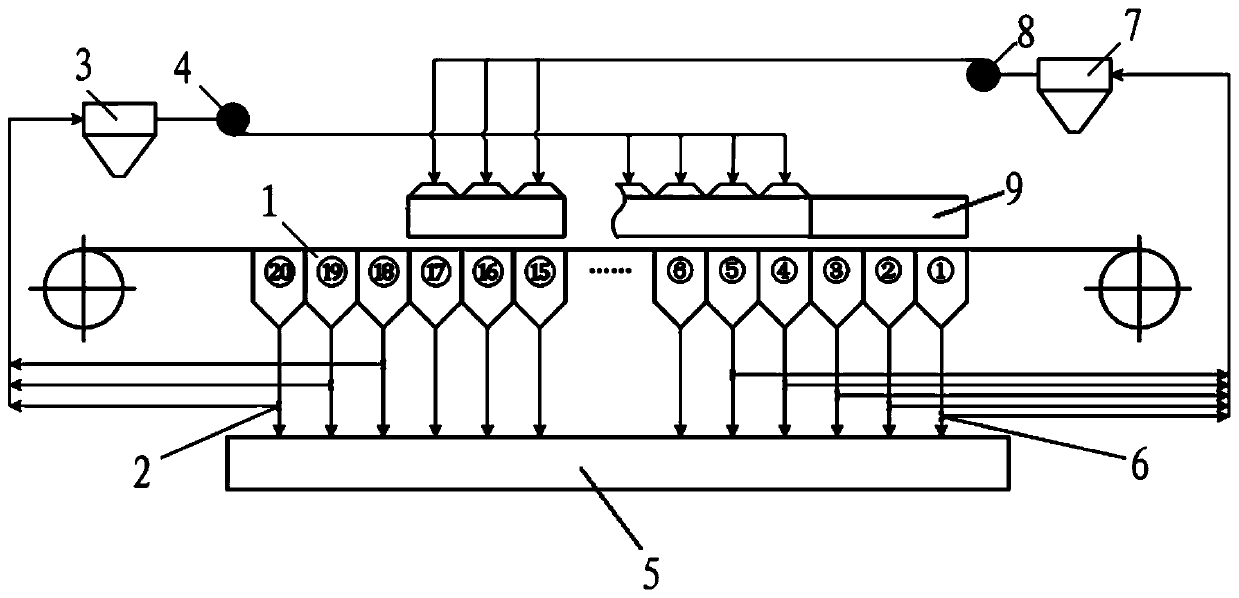

[0017] The embodiment of the present invention provides a sintering system, which solves the technical problem in the prior art that the quality of sintered ore cannot be reduced while reducing pollutant emissions, and achieves the goal of ensuring the quality of sintered ore while reducing pollutant discharge. technical effect.

[0018] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

[0019] The hot flue gas from the air box at the rear of the sintering machine is led back to the material surface at the front of the sintering machine for hot-section cycle sintering, and the cold-section flue gas from the front air box is led back to the material surface at the rear of the sintering machine for cold-section cycle sintering. At the same time, through front and rear cross flue gas circulation, the high-quality flue gas with high temperature and high oxygen in the rear is used to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com