Series preheating method and series preheating system for coal gas of sintering ignition furnace

A technology of ignition furnace and sintering point, which is applied to furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of inability to use large-scale sintering machines, poor ignition effect, and low ignition temperature, so as to improve ignition effect and prolong life. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

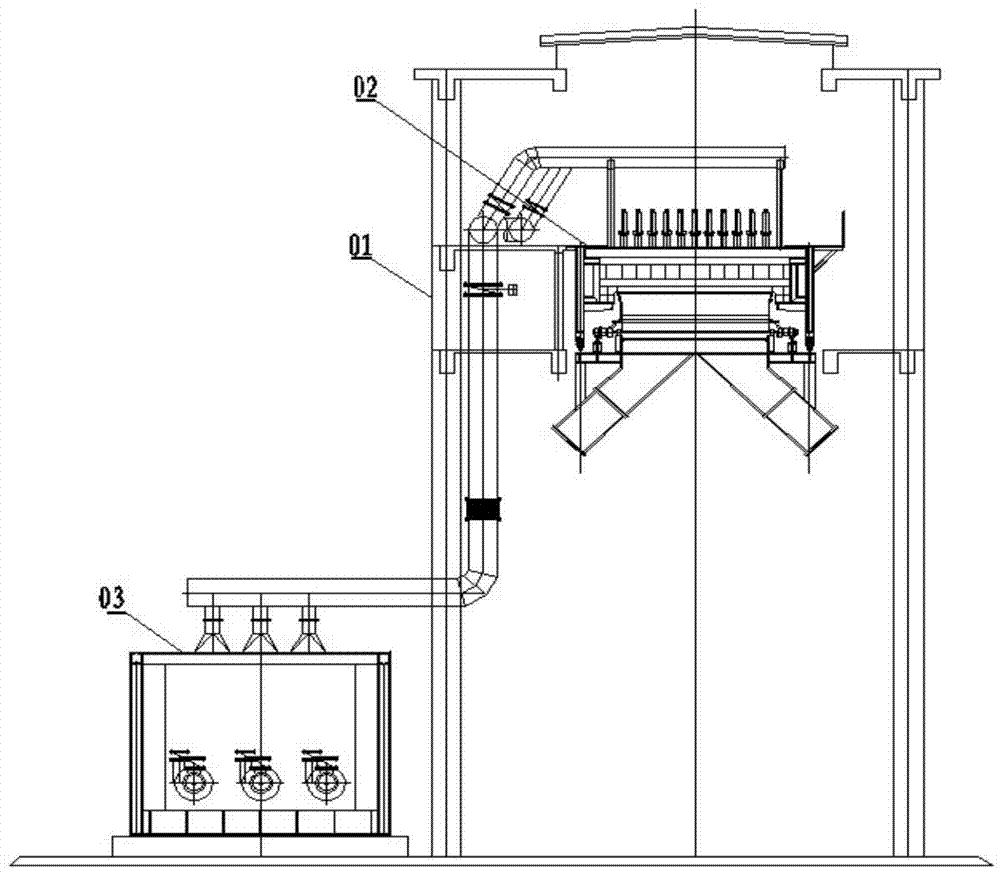

[0027] This embodiment uses a series preheating system of combustion air heat exchanger and gas heat exchanger for sintering ignition furnace, which is arranged under the sintering machine ( figure 1 ), outside the sintering machine workshop 1, the sintering machine is 180m 2 Sintering Machine.

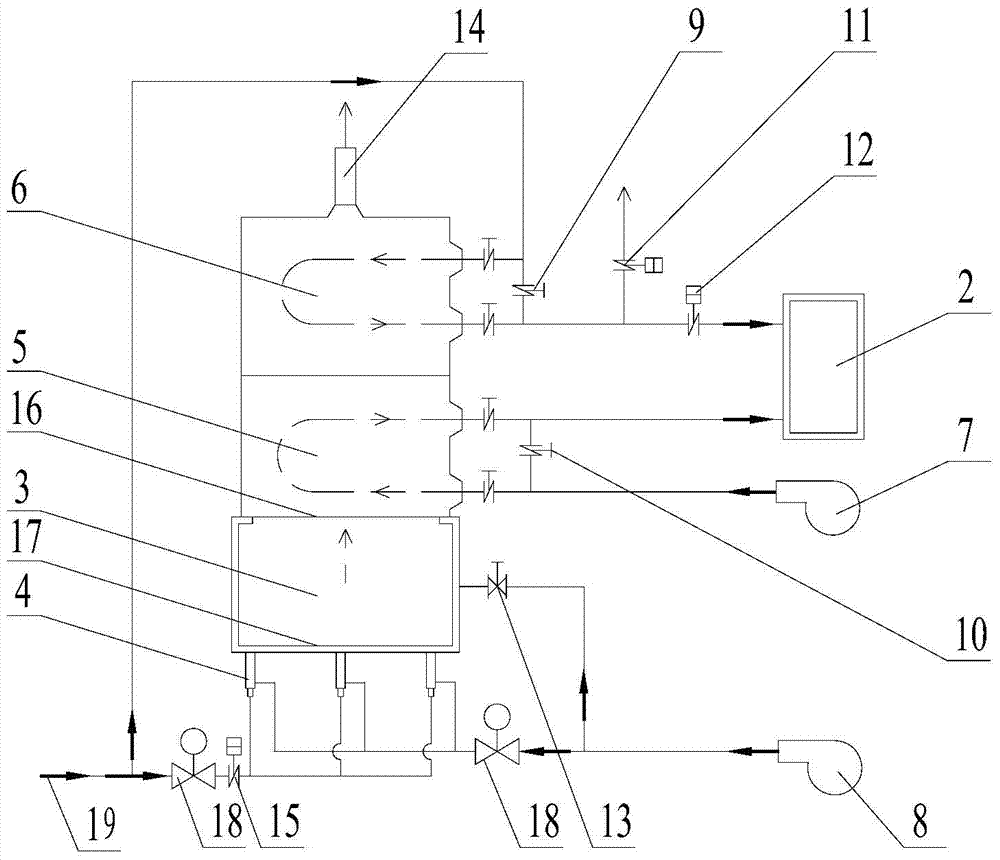

[0028] The sintering ignition furnace uses a combustion air heat exchanger and a gas heat exchanger to preheat the system structure in series ( figure 2 ) Including preheating furnace 3, combustion air heat exchanger 5 for ignition furnace and gas heat exchanger 6 for ignition furnace; preheat furnace 3, combustion air heat exchanger 5 for ignition furnace and gas heat exchanger 6 for ignition furnace The flow direction of the preheating furnace flue gas is arranged in series, the area of the combustion air heat exchanger 5 for the ignition furnace and the gas heat exchanger 6 for the ignition furnace are respectively 110m 2 And 130m 2 . The combustion-supporting air heat exchanger 5 ...

Embodiment 2

[0034] Sintering machine is 300m 2 Sintering Machine. The sintering ignition furnace uses a system for preheating in series with a combustion air heat exchanger and a gas heat exchanger. The heat exchange area of the combustion air heat exchanger 5 and the gas heat exchanger 6 are 180m respectively 2 And 210m 2 . Three burners are arranged on the furnace end wall of preheating furnace 3, and the heating capacity of the burners is 5×10 9 J / h·Taiwan.

[0035] The other settings of the system are the same as in Example 1.

[0036] The preheating furnace uses blast furnace gas (heat value 780kCal / m 3 ) Is the fuel. The combustion-supporting air for the ignition furnace is provided by the combustion-supporting fan 7 for the ignition furnace. When it passes through the combustion-supporting air preheater 5 for the ignition furnace, it undergoes cross-flow convection heat exchange with high-temperature flue gas, and the temperature reaches 330°C; When the coal gas passes through the ga...

Embodiment 3

[0039] Sintering machine is 400m 2 Sintering Machine. The sintering ignition furnace is a series preheating system of combustion air heat exchanger and gas heat exchanger. The heat exchange area of the combustion air heat exchanger and the gas heat exchanger are 220m respectively. 2 And 260m 2 . Three burners are arranged on the furnace end wall of preheating furnace 3, and the heating capacity of the burners is 6.7×10 9 J / h·Taiwan.

[0040] The other settings of the system are the same as in Example 1.

[0041] The preheating furnace uses blast furnace gas (heat value 780kcal / m 3 ) Is the fuel. The combustion air for the ignition furnace is provided by the combustion air fan 7 for the ignition furnace. When it passes through the combustion air preheater 5 for the ignition furnace, it undergoes cross-flow convection heat exchange with the high-temperature flue gas, and the temperature reaches 320℃; When the coal gas passes through the gas preheater 6 for the ignition furnace, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com