Cathode modification layer material and preparation method thereof, and solar cell and preparation method thereof

A cathode modification layer, naphthyl technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor interface contact, affecting the collection of charge carriers by electrodes, limiting the improvement of device efficiency, etc., to reduce work function, The effect of excellent electron transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

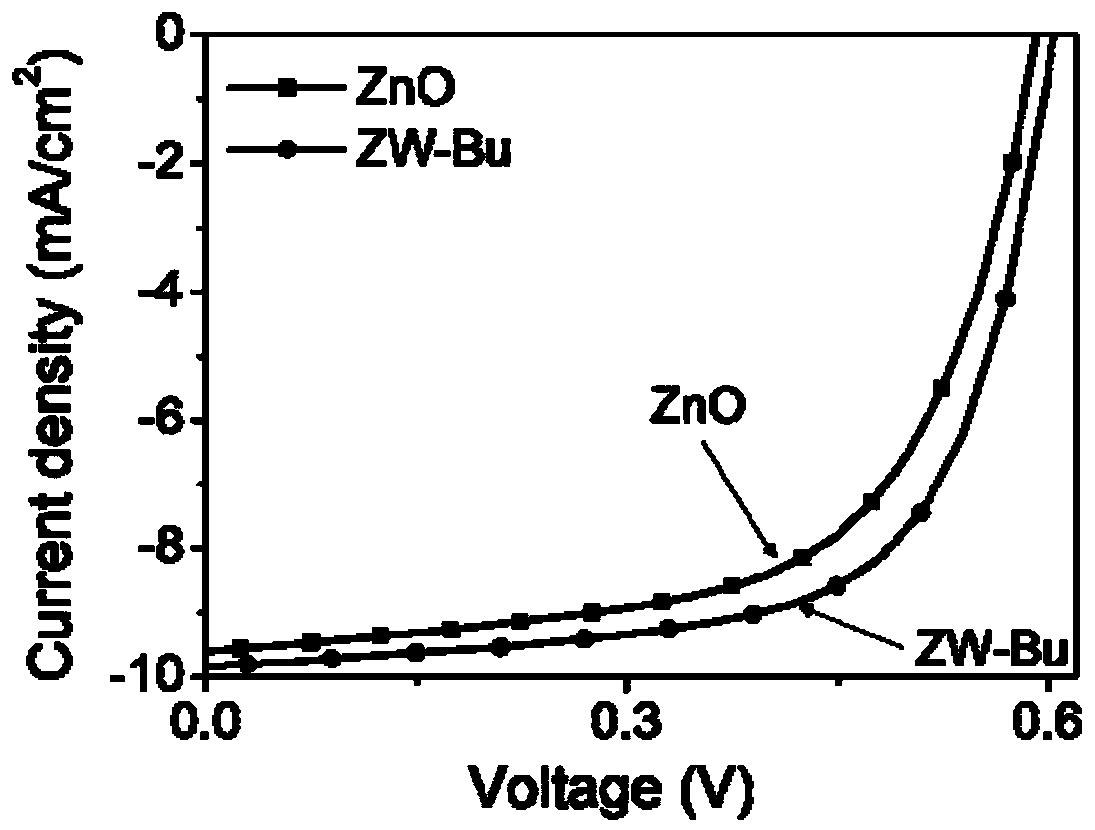

Embodiment 1

[0038] A kind of cathode modification layer material (ZW-Bu), its molecular structural formula is as follows:

[0039]

[0040] The preparation method of the cathode modification layer material comprises the following steps:

[0041] At room temperature, add water to dissolve 4,6-diaminoresorcinol hydrochloride, then add n-butylamine, stop adding when the color of the solution turns purple, and stir for 2 hours, then filter with a funnel, Then use a mechanical pump to filter for 12 hours.

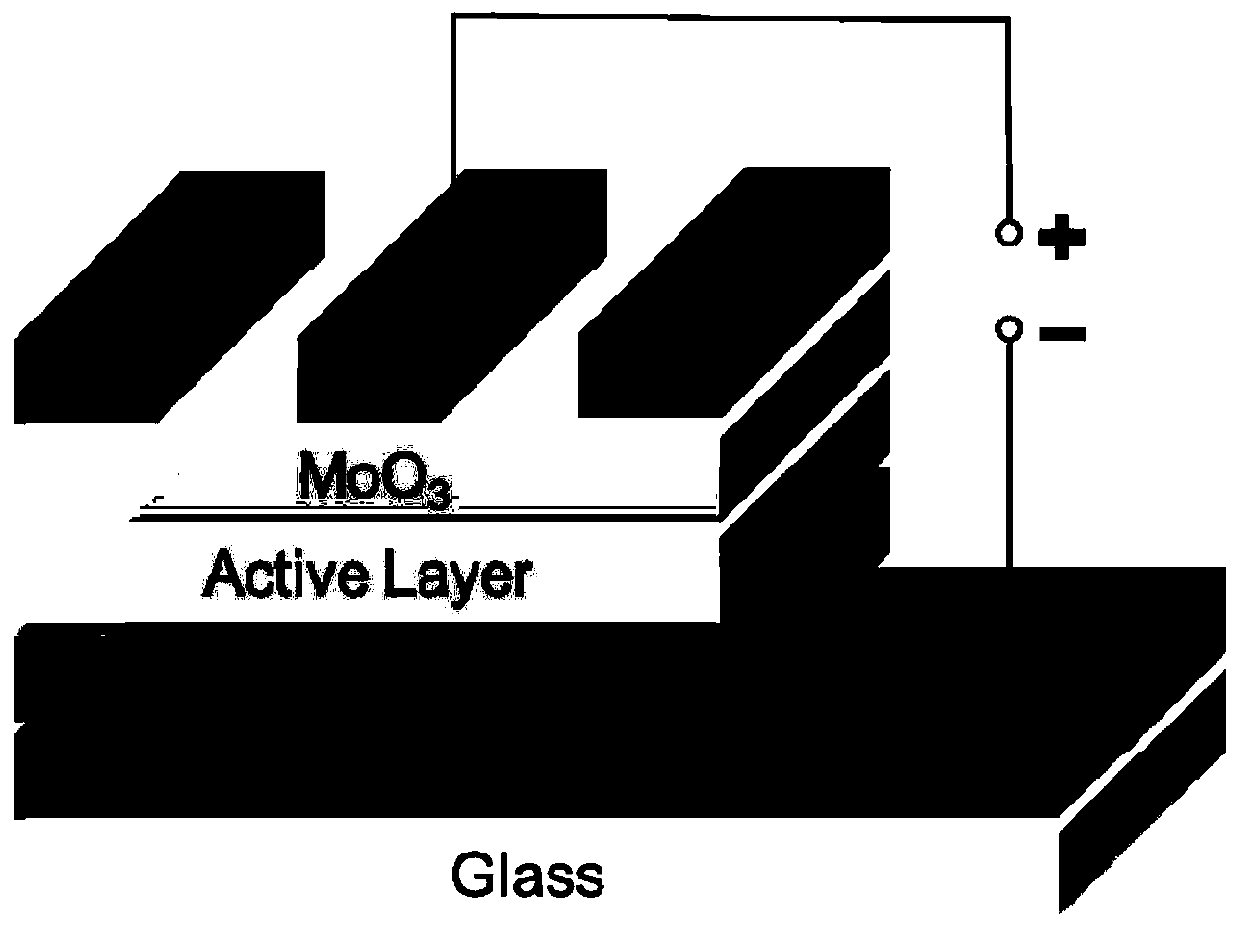

[0042] Using the cathode modification layer material prepared above to prepare a solar cell, the specific process is as follows:

[0043] (1) Select a number of ITO conductive glass from the same batch with a size of 15mm×15mm, a resistance of 20 ohms, and an ITO thickness of 135nm as substrates, and then use detergent, acetone, isopropanol, and ethanol to ultrasonically clean them for 15 minutes. Clean the ITO surface, then dry it with nitrogen, and then place it in an ultraviolet ozo...

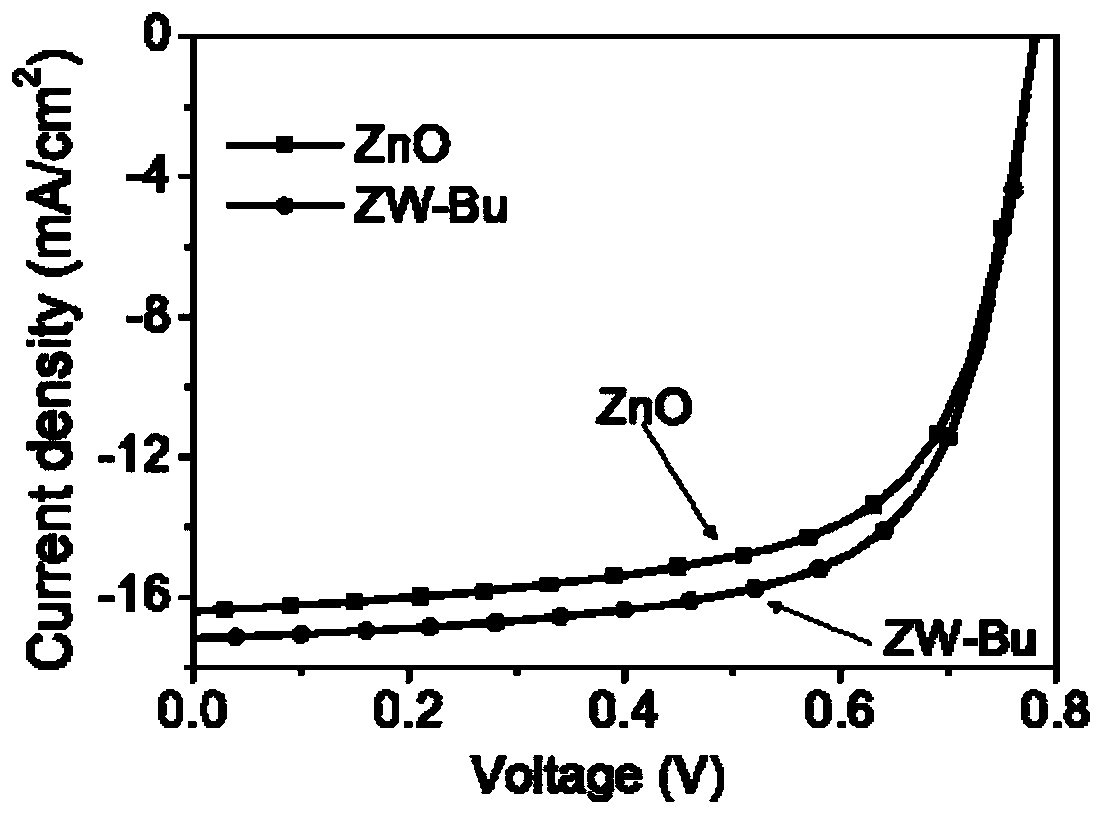

Embodiment 2

[0052] A kind of cathode modification layer material (ZW-Bu), its molecular structural formula is as follows:

[0053]

[0054] The preparation method of the cathode modification layer material comprises the following steps:

[0055] At room temperature, add water to dissolve 4,6-diaminoresorcinol hydrochloride, then add n-butylamine, stop adding when the color of the solution turns purple, and stir for 3 hours, then filter with a funnel, Then use a mechanical pump to filter for 10 hours.

[0056] Using the cathode modification layer material prepared above to prepare a solar cell, the specific process is as follows:

[0057] (1) Select a number of ITO conductive glass from the same batch with a size of 15mm×15mm, a resistance of 20 ohms, and an ITO thickness of 135nm as substrates, and then use detergent, acetone, isopropanol, and ethanol to ultrasonically treat them for 15 minutes. Clean the ITO surface, then dry it with nitrogen, and then treat it under ultraviolet and o...

Embodiment 3

[0066] A kind of cathode modification layer material (ZW-Bu), its molecular structural formula is as follows:

[0067]

[0068] The preparation method of the cathode modification layer material comprises the following steps:

[0069] At room temperature, add water to dissolve 4,6-diaminoresorcinol hydrochloride, then add n-butylamine, stop adding when the color of the solution turns purple, and stir for 2 hours, then filter with a funnel, Then use a mechanical pump to filter for 12 hours.

[0070] Using the cathode modification layer material prepared above to prepare a solar cell, the specific process is as follows:

[0071] (1) Select a number of ITO conductive glass from the same batch with a size of 15mm×15mm, a resistance of 20 ohms, and an ITO thickness of 135nm as substrates, and then use detergent, acetone, isopropanol, and ethanol to ultrasonically treat them for 15 minutes. Clean the ITO surface, then dry it with nitrogen, and then treat it under ultraviolet and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com