A construction method of greening concrete

A technology for greening concrete and construction methods, which is applied in the fields of botanical equipment and methods, marine engineering, planting substrates, etc., can solve problems such as research on water permeability and water retention of concrete, and achieve good mechanical stability, good water permeability, and high resistance. Effects of compressive strength and flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

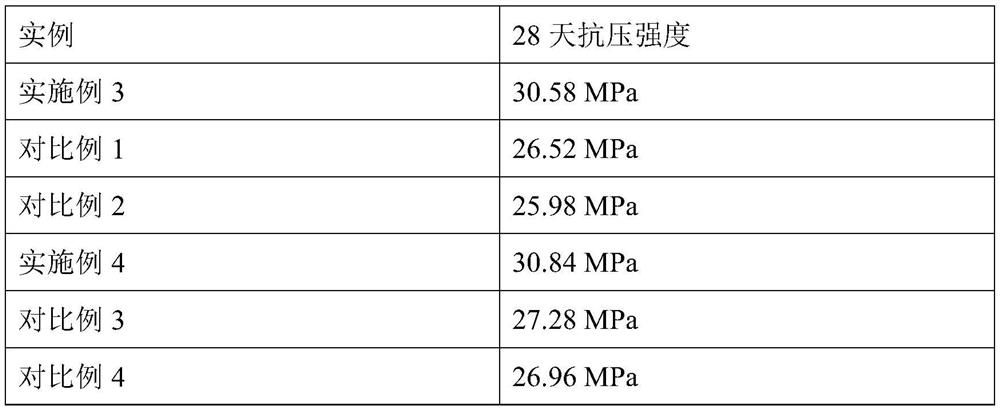

Embodiment 1

[0035] Embodiment 1 A kind of construction method of greening concrete

[0036] Including the following steps:

[0037] (1) Weigh the following components by mass: 400 parts of gravel, 150 parts of cement, 105 parts of fly ash, 70 parts of slag powder, 50 parts of water, carboxymethyl fiber and hydroxyethyl fiber with a mass ratio of 2:1 0.5 parts of cellulose mixture and 4 parts of special additives for greening concrete, the mass ratio of water to cement is 1:3, and the mass ratio of water to fly ash is 1:2;

[0038] (2) mixing the components in the step (1) and then stirring to obtain greening concrete;

[0039] (3) the greening concrete that step (2) is made is laid on the work surface after leveling off, and is scraped off to form a smooth concrete plane;

[0040] (4) Carry out surface hole forming with concrete surface hole forming instrument, make the hole that evenly distributes is formed on the concrete plane in the step (3), the diameter of hole is 20mm, and depth is...

Embodiment 2

[0045] Embodiment 2 A kind of construction method of greening concrete

[0046] Including the following steps:

[0047] (1) Weigh the following components by mass: 600 parts of gravel, 96 parts of cement, 80 parts of fly ash, 67 parts of slag powder, 80 parts of water, carboxymethyl fiber and hydroxyethyl fiber with a mass ratio of 3:1 2 parts of cellulose mixture and 6 parts of special additives for greening concrete, the mass ratio of water to cement is 1:1.2, and the mass ratio of water to fly ash is 1:1;

[0048] (2) mixing the components in the step (1) and then stirring to obtain greening concrete;

[0049] (3) the greening concrete that step (2) is made is laid on the work surface after leveling off, and is scraped off to form a smooth concrete plane;

[0050] (4) Carry out surface hole molding with concrete surface hole forming instrument, make the hole that evenly distributes is formed on the concrete plane in the step (3), the diameter of hole is 25mm, and depth is...

Embodiment 3

[0055] Embodiment 3 A kind of construction method of greening concrete

[0056] Including the following steps:

[0057] (1) Weigh the following components by mass: 400 parts of gravel, 46.8 parts of cement, 70 parts of fly ash, 100 parts of slag powder, 39 parts of water, carboxymethyl fiber and hydroxyethyl fiber with a mass ratio of 2.5:1 5.5 parts of cellulose mixture and 8 parts of special additives for greening concrete, the mass ratio of water to cement is 1:1.2, and the mass ratio of water to fly ash is 1:1.8;

[0058] (2) mixing the components in the step (1) and then stirring to obtain greening concrete;

[0059] (3) the greening concrete that step (2) is made is laid on the work surface after leveling off, and is scraped off to form a smooth concrete plane;

[0060] (4) Carry out surface hole molding with concrete surface hole forming instrument, make the hole that evenly distributes is formed on the concrete plane in step (3), the diameter of hole is 30mm, and dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com