A detection method for stacked steel of cold-rolled wire rods based on the Internet of Things

A detection method and technology of the Internet of Things, which are applied in metal rolling, length measuring device, metal rolling, etc., can solve the problems of inflexible and intelligent detection of cold-rolled wire rod stacking, affecting rolling efficiency, and personal safety threats. , to achieve the effect of flexible and intelligent detection, saving maintenance time, and speeding up the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

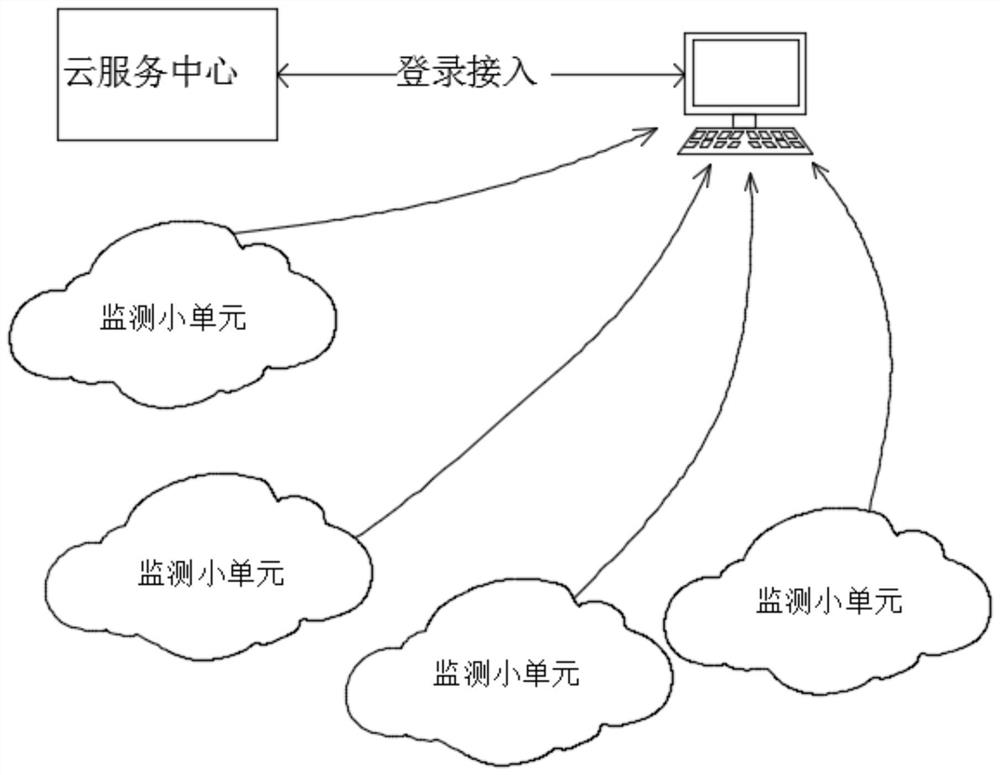

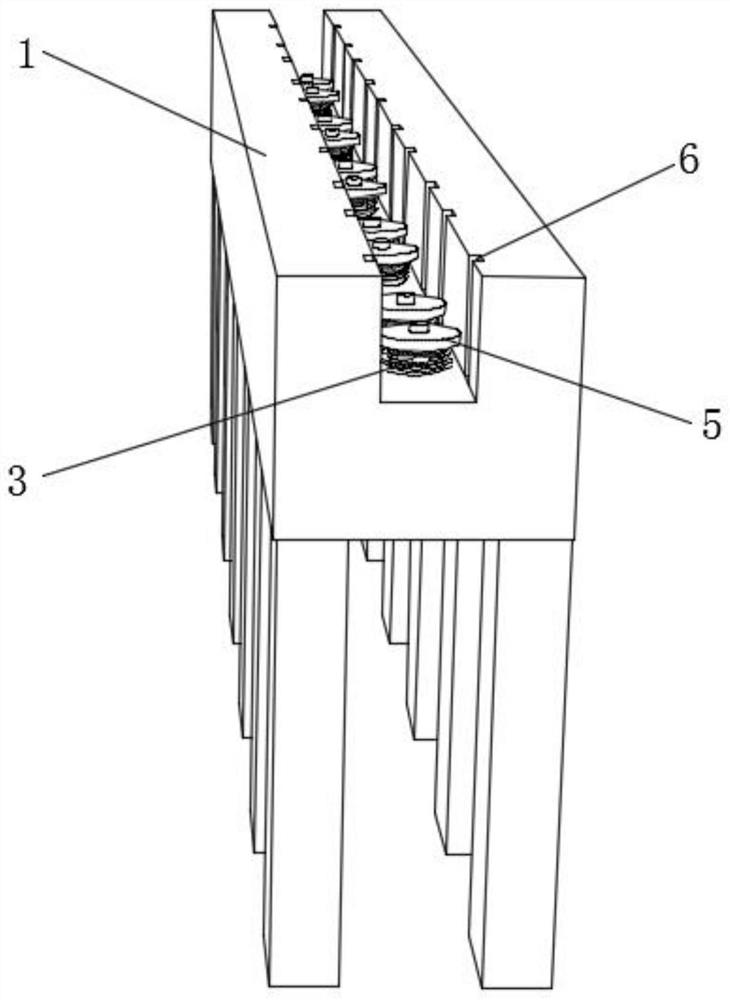

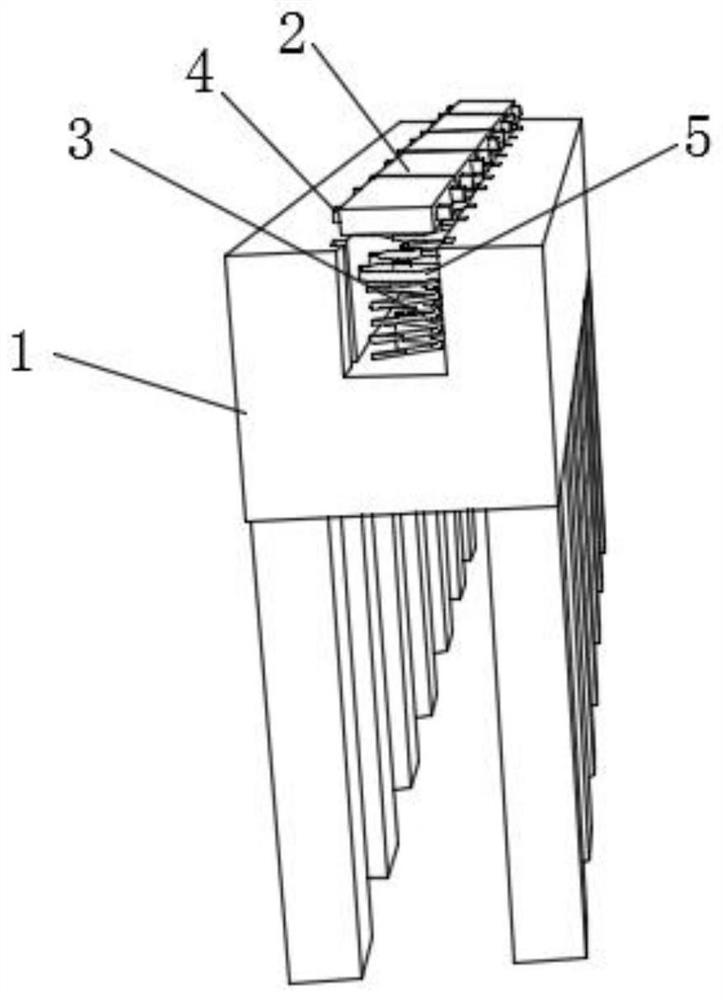

[0045] See figure 1 , A cold-rolled wire rod pile detection method based on the Internet of Things, including a detection station 1 with a built-in controller connected to a computer signal, a real-time monitoring unit is set on the detection station 1, and the real-time monitoring unit is connected to the computer signal through the controller, The real-time monitoring unit includes a plurality of small monitoring units. The upper end of the detection platform 1 has a placement slot for cold-rolled wire rods. The multiple monitoring small units are evenly distributed in the placement slot, and each monitoring small unit is equipped with a memory storage chip. The memory storage chip is electrically connected to the controller, and the lifting plate assembly is placed inside the placement slot. Based on the intelligent control of the Internet of Things computer, the multi-point detection makes the detection of cold-rolled wire stacks flexible and intelligent, and it is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com