High-strength slow-crosslinked chromic gel and preparation method thereof

A high-strength, jelly technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of too fast gelation time and easy damage to the gelation strength, so as to prolong the gelation time and improve the gelling time. Strength and stability, and the effect of delaying the gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

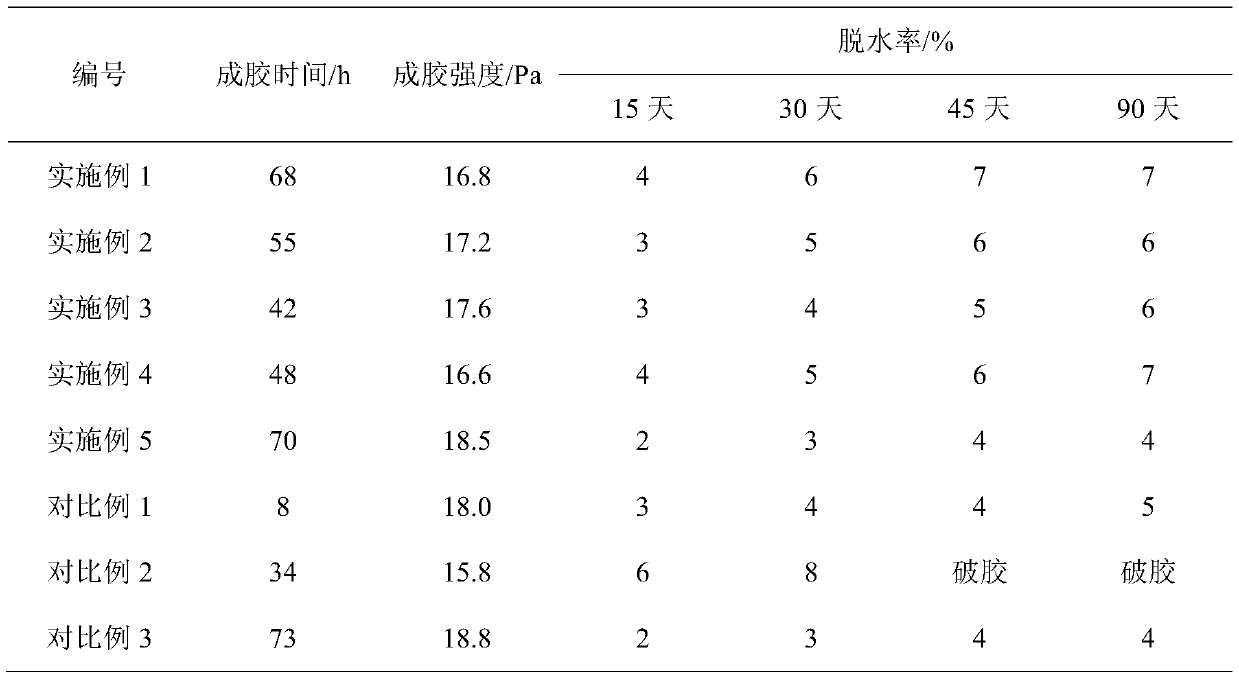

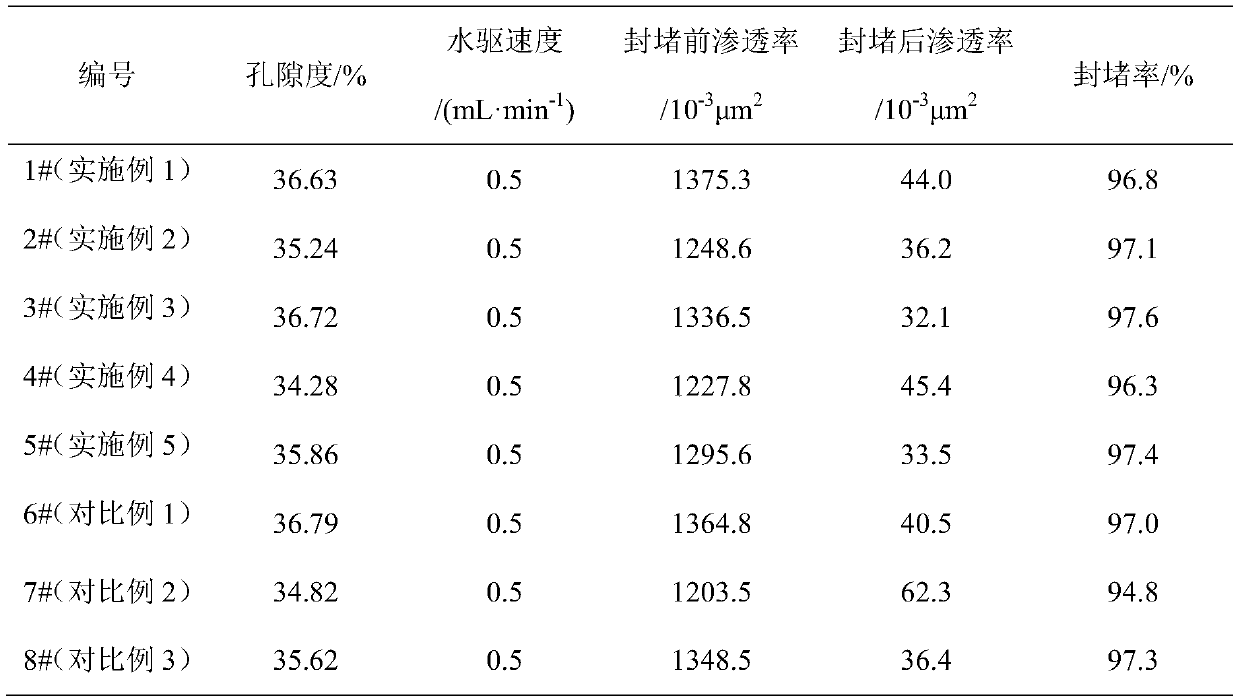

Examples

Embodiment 1

[0032] First, prepare a 5% cationic AM / DAC binary copolymer mother liquor with a mass fraction of 2%, add 40g AM / DAC binary copolymer mother liquor, 0.3g chromium acetate and 1.0g aluminum sol in a beaker, and then add water to mix the solution Make up to 100g and stir well to obtain a gelatinous liquid. Place the gelatinous liquid in an ampoule, sinter and seal it with an alcohol blowtorch, and place it in a constant temperature water bath at 90°C for aging to obtain the jelly of the present invention.

Embodiment 2

[0034] First, prepare a 15% cationic AM / DAC binary copolymer mother liquor with a mass fraction of 2%, add 40g AM / DAC binary copolymer mother liquor, 0.3g chromium acetate and 1.0g aluminum sol in a beaker, and then add water to mix the solution Make up to 100g and stir well to obtain a gelatinous liquid. Place the gelatinous liquid in an ampoule, sinter and seal it with an alcohol blowtorch, and place it in a constant temperature water bath at 90°C for aging to obtain the jelly of the present invention.

Embodiment 3

[0036] First, prepare a 30% cationic AM / DAC binary copolymer mother liquor with a mass fraction of 2%, add 40g AM / DAC binary copolymer mother liquor, 0.3g chromium acetate and 1.0g aluminum sol in a beaker, and then add water to mix the solution Make up to 100g and stir well to obtain a gelatinous liquid. Place the gelatinous liquid in an ampoule, sinter and seal it with an alcohol blowtorch, and place it in a constant temperature water bath at 90°C for aging to obtain the jelly of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com