Centrifugal pump pressure water chamber

A pressurized water chamber and centrifugal pump technology, which is applied in the field of centrifugal pumps, can solve problems such as delamination and fracture, and the coating adhesion has not been greatly improved, and achieve the effects of inhibiting wear, facilitating processing, and optimizing internal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

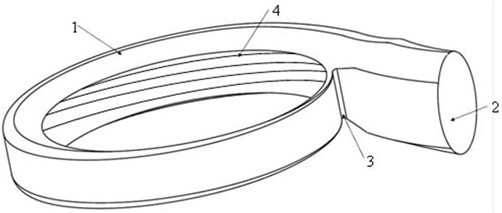

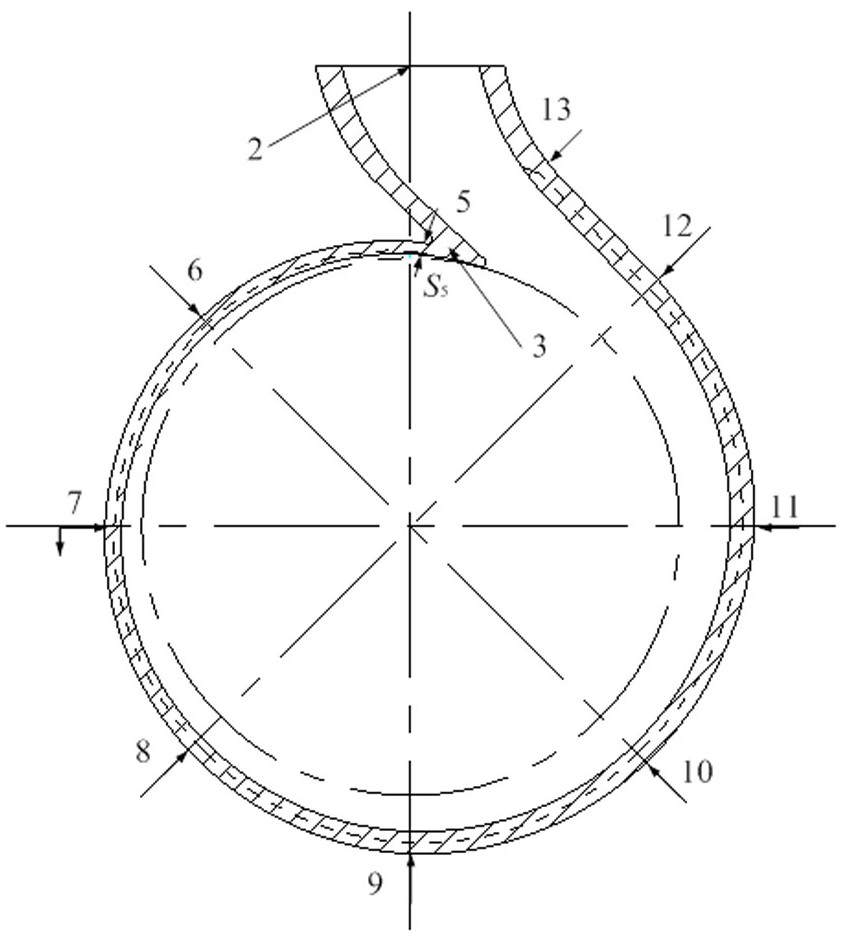

[0009] Such as figure 1 , figure 2 As shown, the present invention is a centrifugal pump pressurized chamber, comprising a pressurized chamber housing 1, an outlet 2 of the pressurized chamber, and a tongue 3 of the pressurized chamber. Groove 4 spreads along the pressurized water chamber partition tongue 3 to the direction of the pressurized water chamber outlet 2.

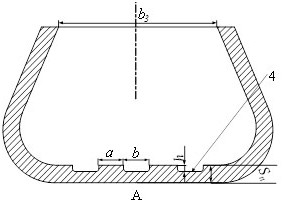

[0010] Such as figure 1 , figure 2 As shown, the pressure water chamber of the centrifugal pump of the present invention includes a pressure water chamber housing 1 , an outlet 2 of the pressure water chamber, a tongue 3 and a groove 4 in the pressure water chamber. The shape of the pressurized water chamber is spiral, and the cross-sectional shape of each flow is trapezoidal. The projection shape of the groove 4 on the plane is consistent with the shape of the flow channel of the pressure water chamber housing 1. The grooves are opened from the pressure water chamber partition tongue 3 and end at the ninth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com