Inner sound quality improvement system caused by vehicle carbon tank

A sound quality and carbon canister technology, applied in the field of interior sound quality improvement systems, can solve problems such as high cost, complexity, and poor noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

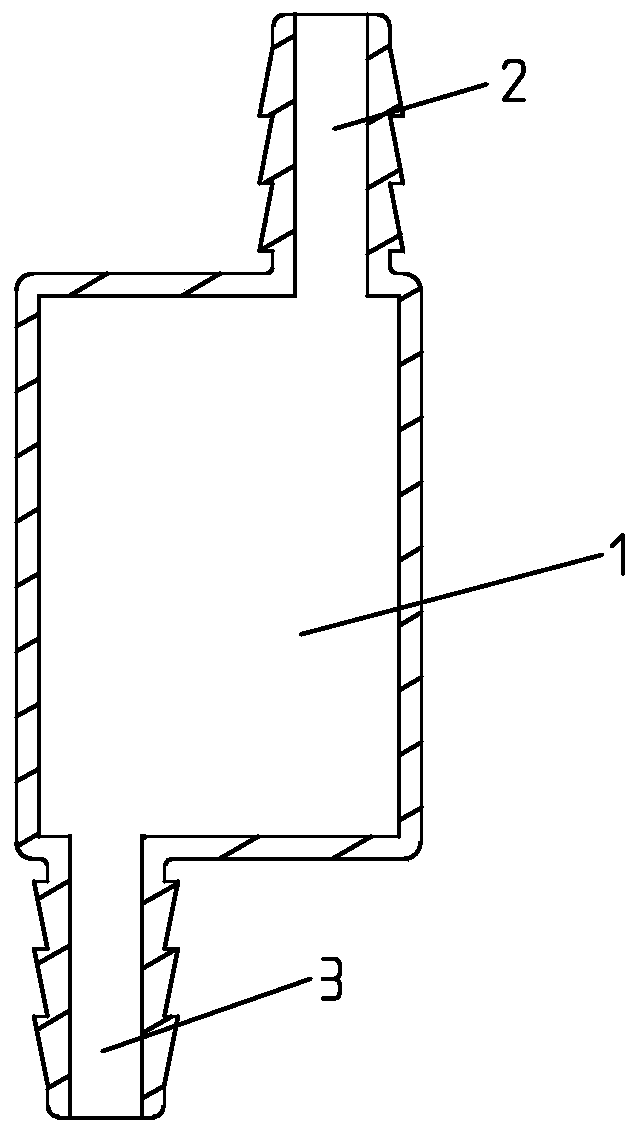

[0030] The first embodiment of the present invention, as attached figure 1 , the inner cavity of the body 1 is a pure cavity structure, and the centerline of the air inlet hole 2 and the centerline of the air outlet hole 3 are not on the same straight line. When the pressure pulsation passes through the inner cavity of the body 1, most of the kinetic energy can be attenuated, thereby effectively buffering and reducing the pulsation energy on the canister desorption tube, and finally reducing the pulsation noise inside the car when idling and low speed driving, improving Interior sound quality characteristics.

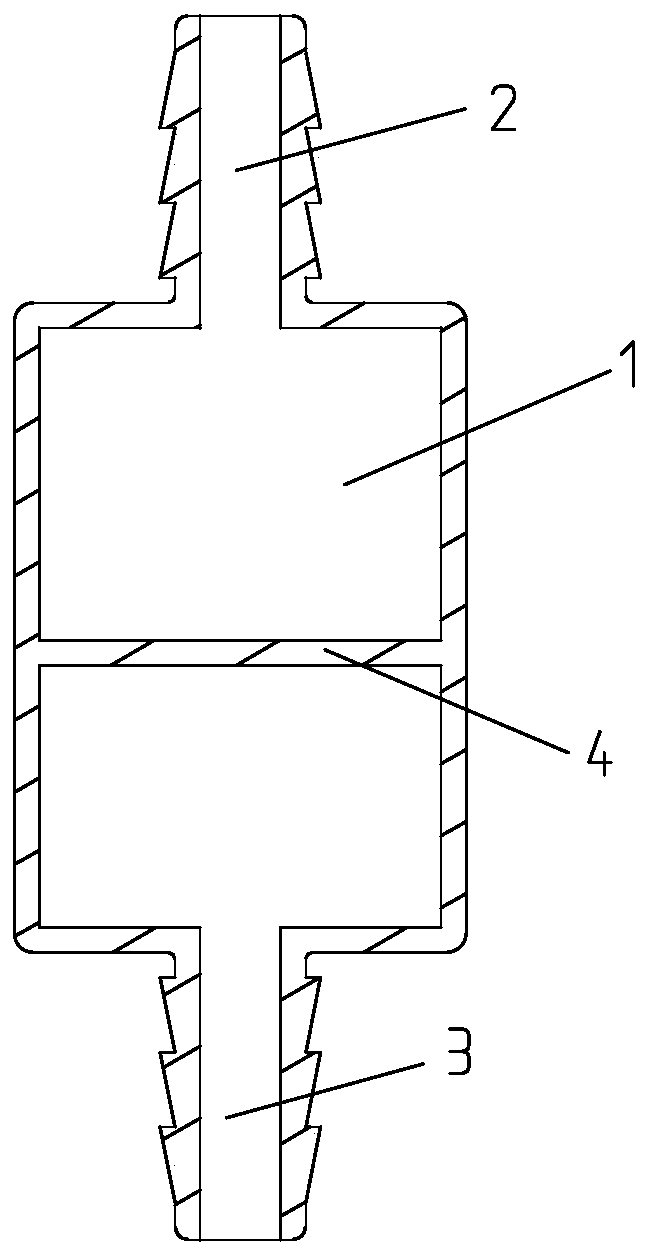

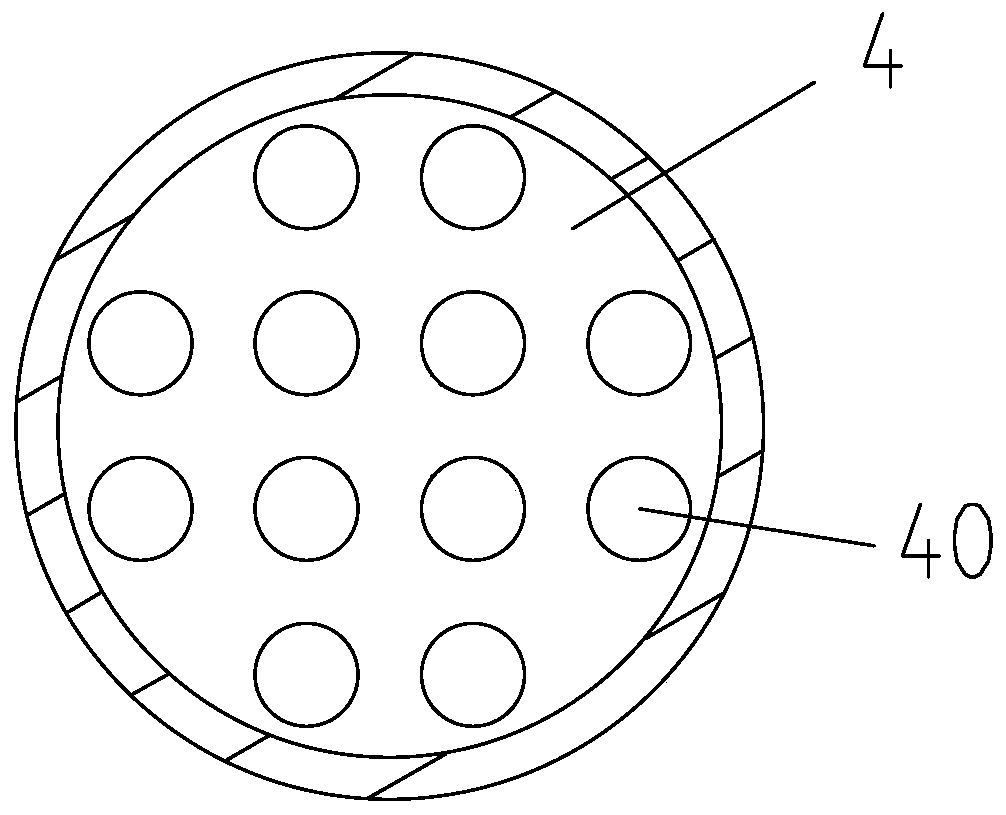

[0031] The second embodiment of the present invention, as attached figure 2 And attached image 3 As shown, the center line of the air inlet hole 2 and the air outlet hole 3 are on the same straight line, and a baffle plate 4 is provided in the cavity of the body 1, and a plurality of through holes 40 are distributed on the baffle plate 4 . The baffle plate 4 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com